High-power factor active valley-fill type alternating current and direct current converter

An AC-DC conversion and high power factor technology, applied in the electronic field, can solve problems such as difficult to further improve the AC input power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

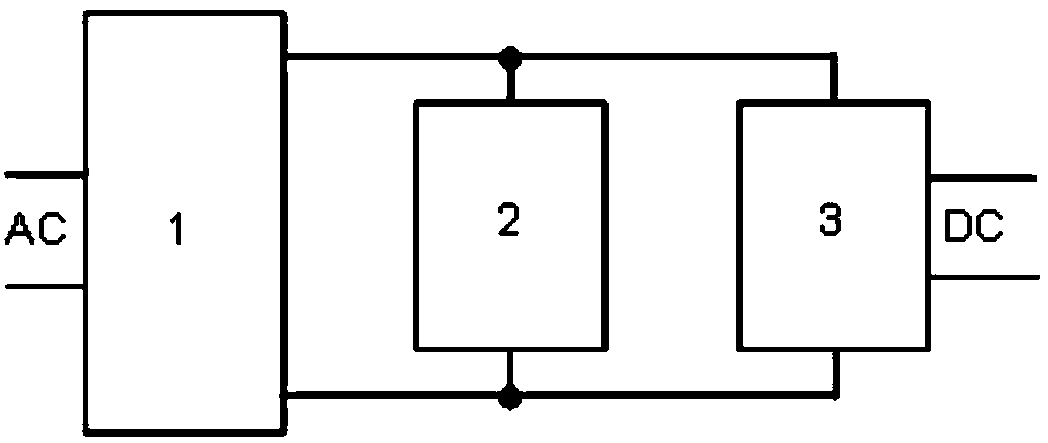

[0053] Embodiment 1, a high power factor active valley filling AC-DC converter, such as Figure 5 Shown: including a diode rectifier bridge 1, an active nonlinear capacitor network 2 and a subsequent switching power converter 3.

[0054] 1. The diode rectifier bridge 1 consists of 4 diodes (conventional technology).

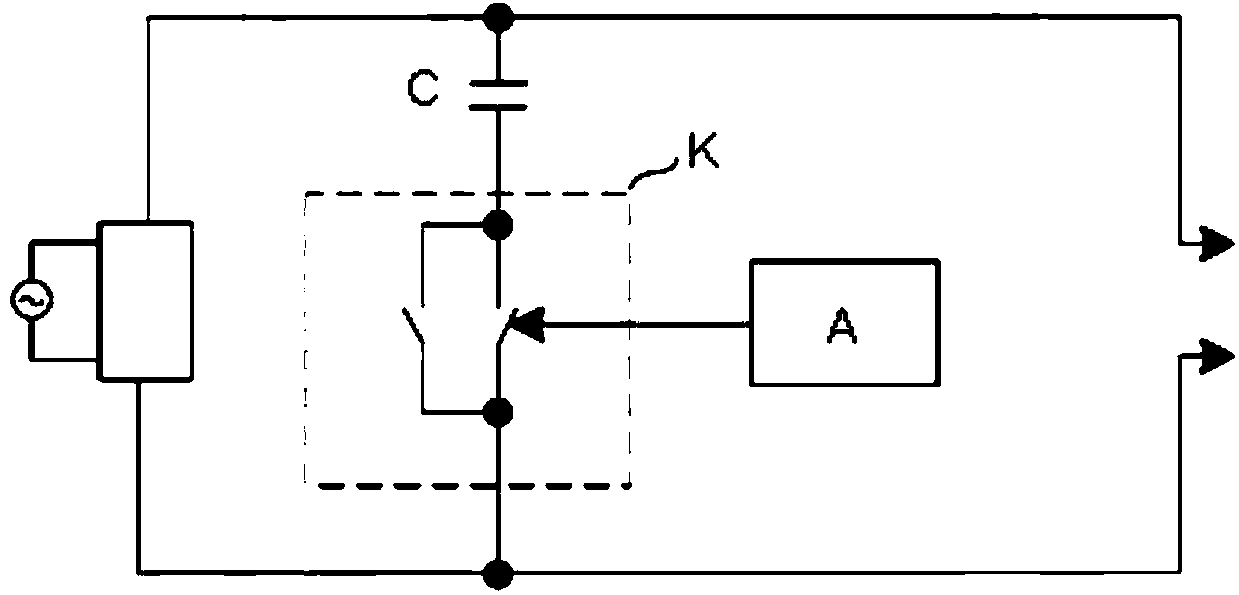

[0055] 2. The active nonlinear capacitor network 2 is specifically composed of an energy storage capacitor C, a switch network, a switch control module A and a switch K.

[0056] The switch network is composed of active switch M, inductor L and freewheeling diode D. The switch K is a bidirectional switch.

[0057] The electrical connection relationship of the active nonlinear capacitor network 2 is as follows: the energy storage capacitor C is connected in series with the switch K to form a branch; the freewheeling diode D is connected in series with the active switch M to form another branch; the above two The branches are connected in parallel with each othe...

Embodiment 2

[0071] However, in Embodiment 1, the charging circuit of the energy storage capacitor C needs an active switch M, an inductor L and a freewheeling diode D, which increases the cost and complexity of the entire system. In energy-saving lamps, LED lighting and other low-power and cost-sensitive products, the present invention can also be used to realize a low-cost and high-power-factor active valley-filling AC-DC converter. Due to the low power of energy-saving lamps, LED lighting, etc., the value of the energy storage capacitor C in the active nonlinear capacitor network 2 can be selected as a relatively low value, such as a capacitance value between 0.1uF and 4.7uF. There are many types of capacitors; in addition to electrolytic capacitors, there are film capacitors, ceramic dielectric capacitors, and so on. The life of electrolytic capacitors is affected by the ambient temperature in which they work. When the ambient temperature increases by ten degrees, the life of the electr...

Embodiment 3

[0089] Embodiment 3, as Figure 7 As shown, a conventional N-channel MOSFET is used as the switch K (in contrast, a P-channel MOSFET in Example 2); the rest are identical to Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com