Resin composition, resin pellet, method for manufacturing resin pellet, and solar battery sealant

A technology of resin composition and resin particles, which can be used in circuits, photovoltaic power generation, electrical components, etc., and can solve problems such as particle adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

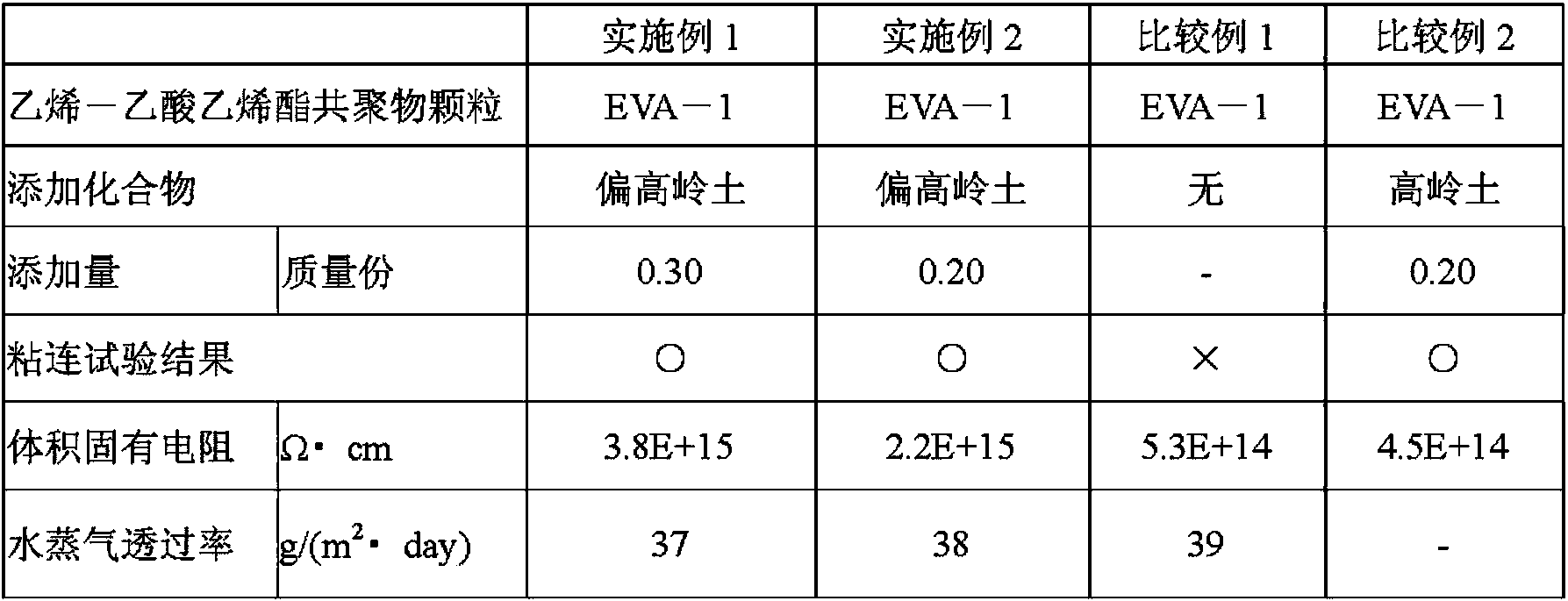

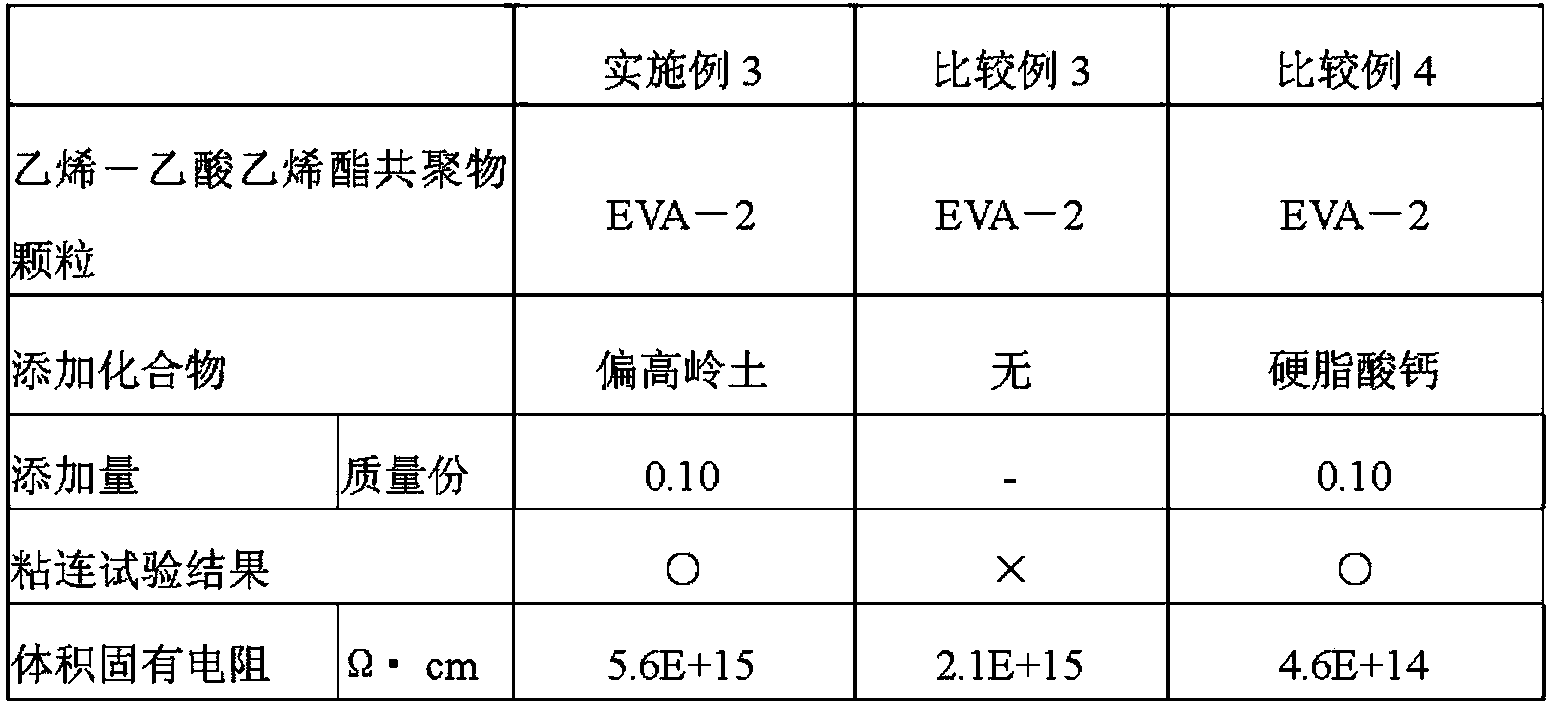

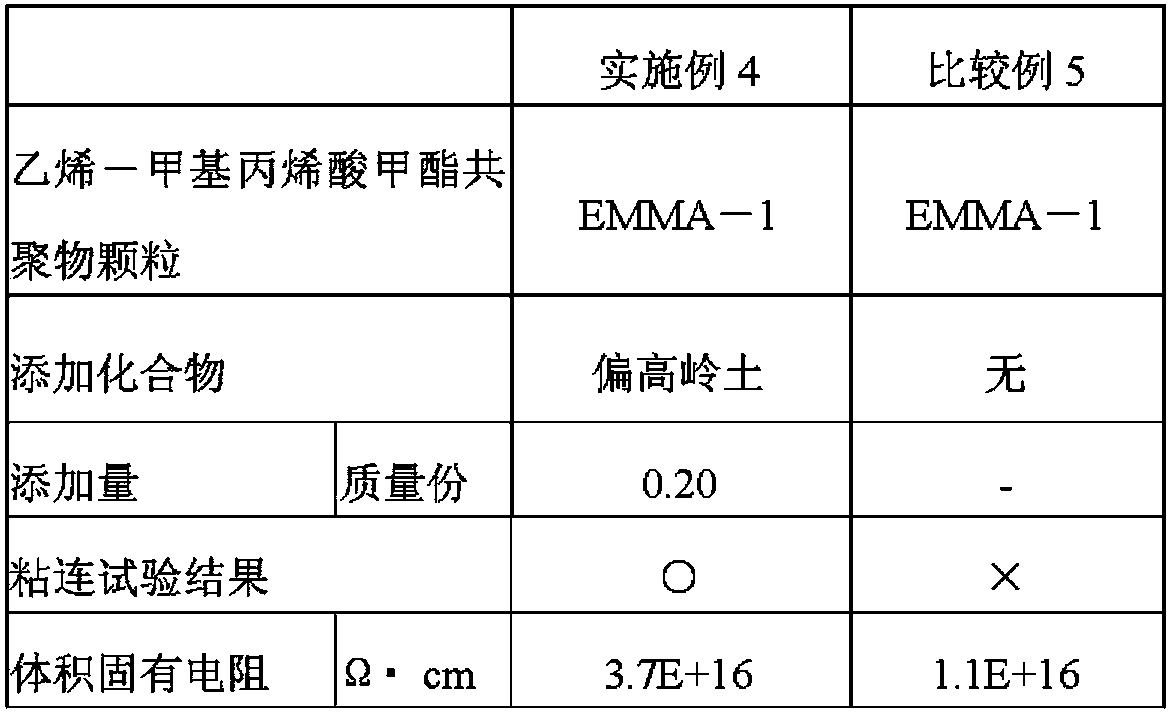

[0064] Below, the present invention is further described in detail through examples.

[0065] (experiment method)

[0066] The particle adhesion test and the measurement of physical properties in Examples and Comparative Examples were performed by the following methods.

[0067] 〔Particle adhesion test〕

[0068] Put 32g of sample particles into a plastic bag with a zipper of 60mm×85mm, and close the zipper. Next, in an atmosphere of 40°C, apply 900g / cm 2 After maintaining this state for 24 hours under a load of 5° C., this state was maintained for 24 hours. The load was then unloaded and the bags were kept at 23°C for 24 hours. Then, the bag was broken to take out the pellets, and the non-adhesiveness of the pellets was observed and evaluated based on the following criteria.

[0069] ○: No adhesion between particles

[0070] ×: 5 or more particles closely adhere to each other

[0071] 〔Volume intrinsic resistance (unit: Ω cm)〕

[0072] The pellets after the blocking te...

Embodiment 1

[0092]Using an autoclave reactor, under the conditions of reaction temperature 188-195°C, reaction pressure 180-185MPa, feed gas composition (ethylene: 63-68% by mass, vinyl acetate: 37-32% by mass), use peroxide - tert-butyl 2-ethylhexanoate was used as an initiator to synthesize ethylene-vinyl acetate copolymer. The obtained ethylene-vinyl acetate copolymer was pelletized using an extruder to obtain ethylene-vinyl acetate copolymer pellets. Put 32g of ethylene-vinyl acetate copolymer particles (32% by mass of structural units derived from vinyl acetate, MFR37g / 10min, molecular weight distribution 3.8, hereinafter referred to as EVA-1.) into a polyethylene bag 0.096g of metakaolin (Isoturaite MC-6, manufactured by Mizusawa Chemical Industry Co., Ltd., average particle diameter 6 μm) (with respect to 100 parts by mass of EVA-1, metakaolin is 0.3 parts by mass), stirred for 2 minutes, and then carried out the blocking test . The volume resistivity was measured using the resin...

Embodiment 2

[0094] Except having used 0.064g of metakaolin, it implemented similarly to Example 1 (metakaolin is 0.2 mass parts with respect to 100 mass parts of EVA-1). The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com