High flow liquid crystalline polymer composition

A technology for liquid crystal polymers and compositions, applied in liquid crystal materials, chemical instruments and methods, etc., can solve problems such as adversely affecting the thermal and mechanical properties of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

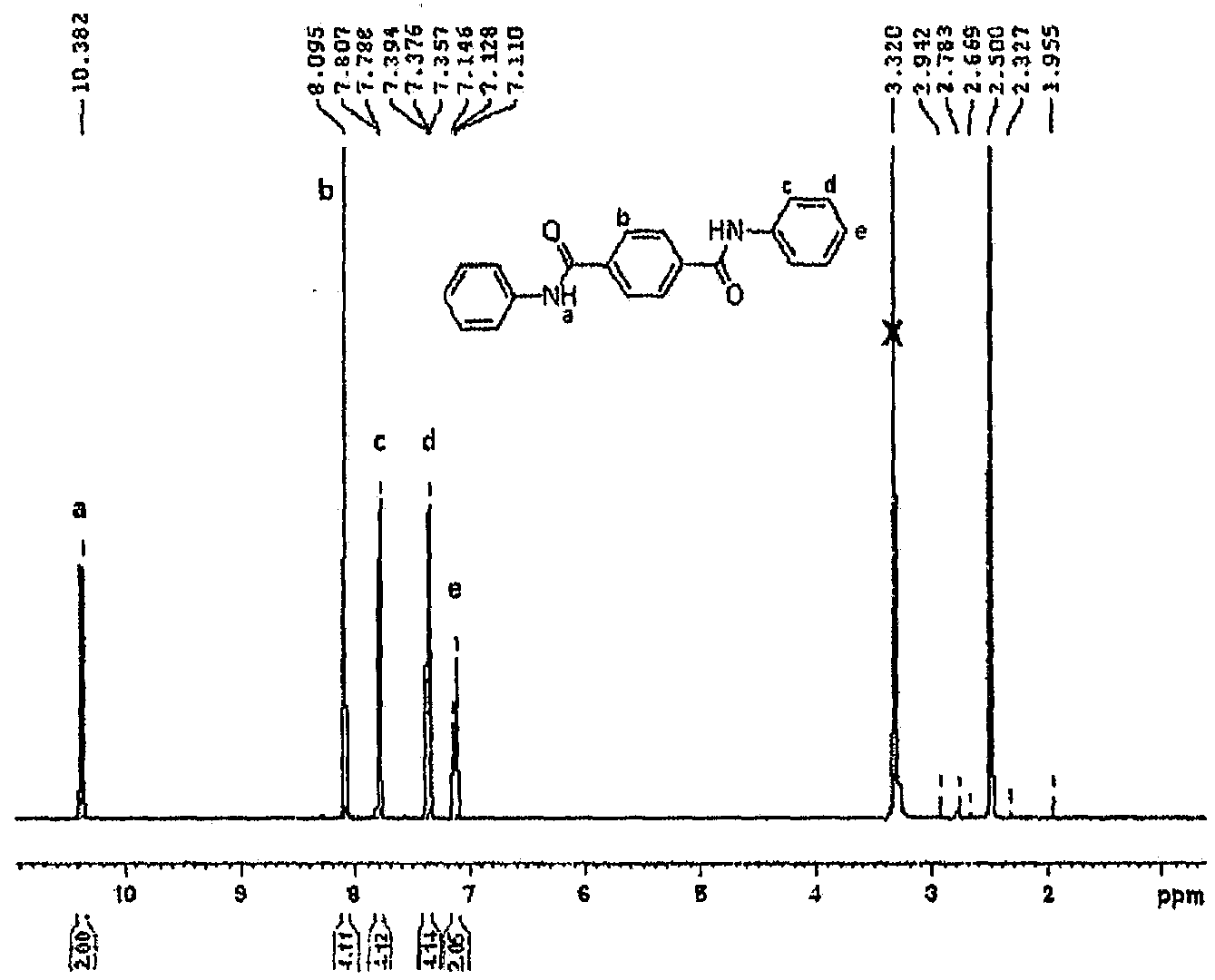

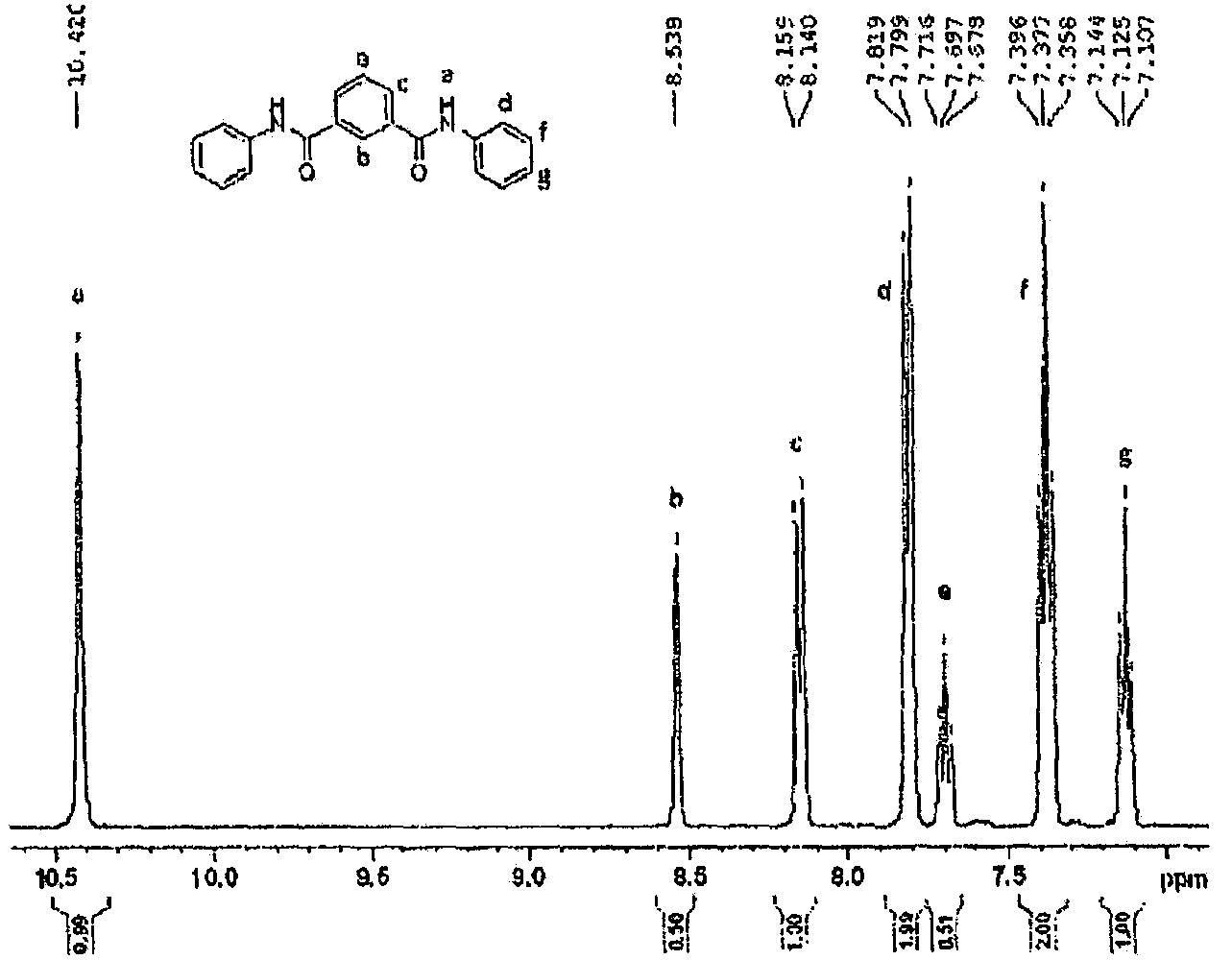

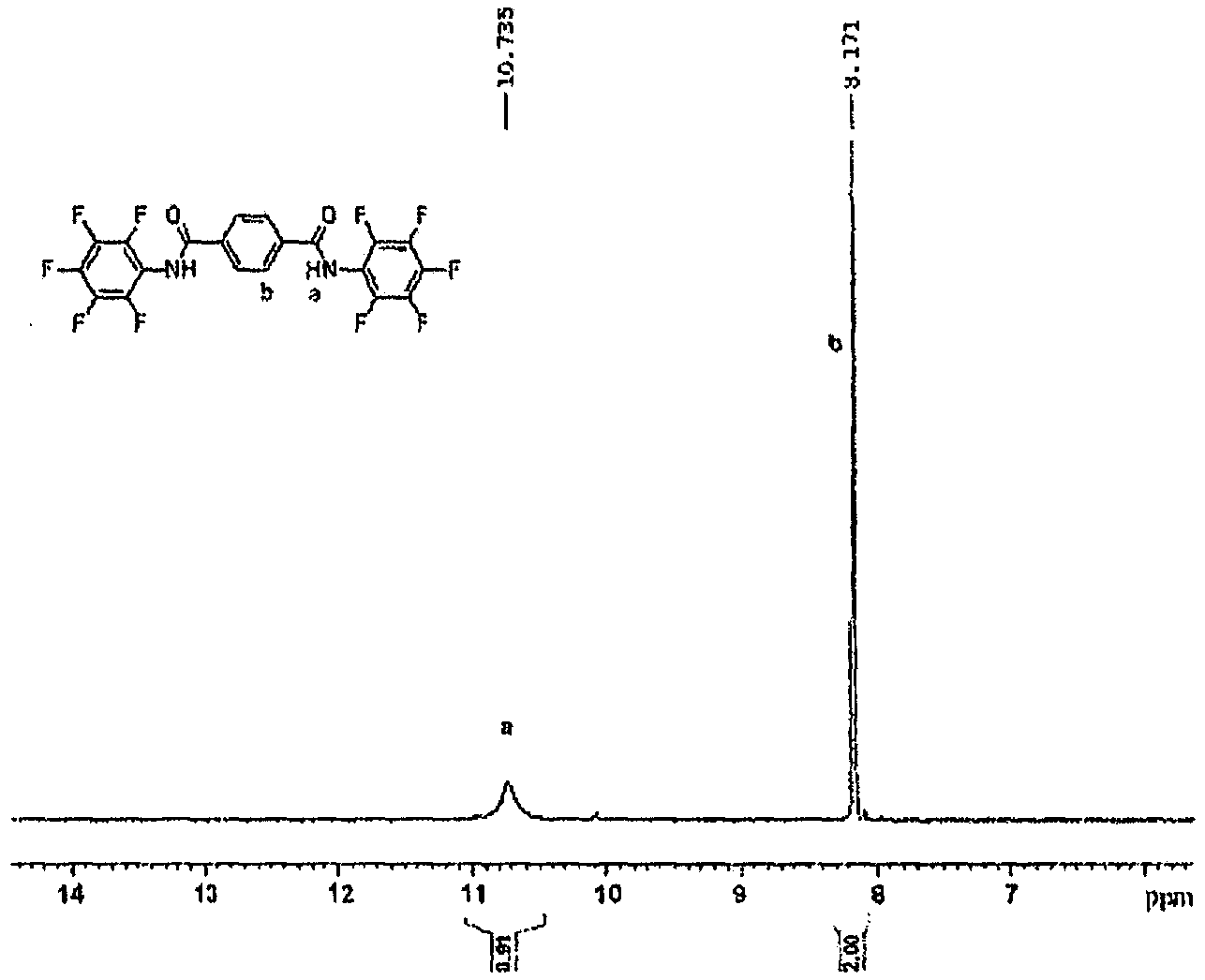

Method used

Image

Examples

Embodiment 1

[0147] Compound A was synthesized as described above and tested for its effect on the melt viscosity of a polymer commercially available from Ticona, LLC having the following monomer content: 63% 4-hydroxybenzoic acid ("HBA"), 5% 2,6-hydroxynaphthoic acid (“HNA”), 16% terephthalic acid (“TA”), 11% 4,4’-bisphenol (“BP”) and 5% paracetamol (“ APAP"). More specifically, the polymer was heated at 120°C and powder coated with pentaerythritol tetrastearate (PETS, commercial grade Lonza Glycolube P) at a loading of 0.3 wt.% based on polymer weight. Compound A was tested at various concentrations. The result is shown below.

[0148]

[0149] As shown, even a small amount of Compound A produces a significant decrease in melt viscosity.

Embodiment 2

[0151] Compound A was synthesized as described above and its effect on the melt viscosity of the commercial grade polymers and filler materials used in Example 1 was tested. More specifically, a control sample was synthesized by heating the polymer at 120 °C and powder-coating it with pentaerythritol tetrastearate (PETS, commercial grade Lonza Glycolube P) at a loading of 0.3 wt% (based on polymer). Cloth the polymer. The coated polymer was then compounded with glass and talc fillers in a 25-mm extruder. Another sample was prepared in a similar manner, except that it contained 1 wt.% of Compound A. The compositions and their respective properties are shown below.

[0152] combination

[0153] intrinsic viscosity

[0154] As shown, Compound A was able to reduce viscosity even in the presence of filler materials.

Embodiment 3

[0156] Compounds A, B, C, E, F2 and G2 were synthesized as described above and their effect on the melt viscosity of the commercial grade polymer used in Example 1 was tested. More specifically, the polymer was heated at 120°C and powder coated with pentaerythritol tetrastearate (PETS, commercial grade Lonza Glycolube P) at a loading of 0.3 wt.% based on polymer weight. The thermal pellets were then coated with 2 wt.% (based on polymer weight) of one of Compounds A, B, C, E, F2 and G2. A control sample was also formed which used 4,4'-bisphenol in an amount of 2 wt.% as flow additive. The mixture was then melt compounded using a Leistritz 18 mm co-rotating fully intermeshing twin screw extruder with 6 temperature control zones (including at the extrusion die) and a total L / D of 30. A general purpose screw design was used to compound the oligomers into the resin matrix. All materials were fed via volumetric feeders to the feed inlet in the first barrel. The material is melted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com