Counter-rotating end milling cutter

A technology of reverse rotation and end milling cutter, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of milling cutters becoming blunt, machining cutting amount not meeting processing needs, and increasing production costs, etc., to achieve greater The effect of processing cutting amount, reducing processing cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

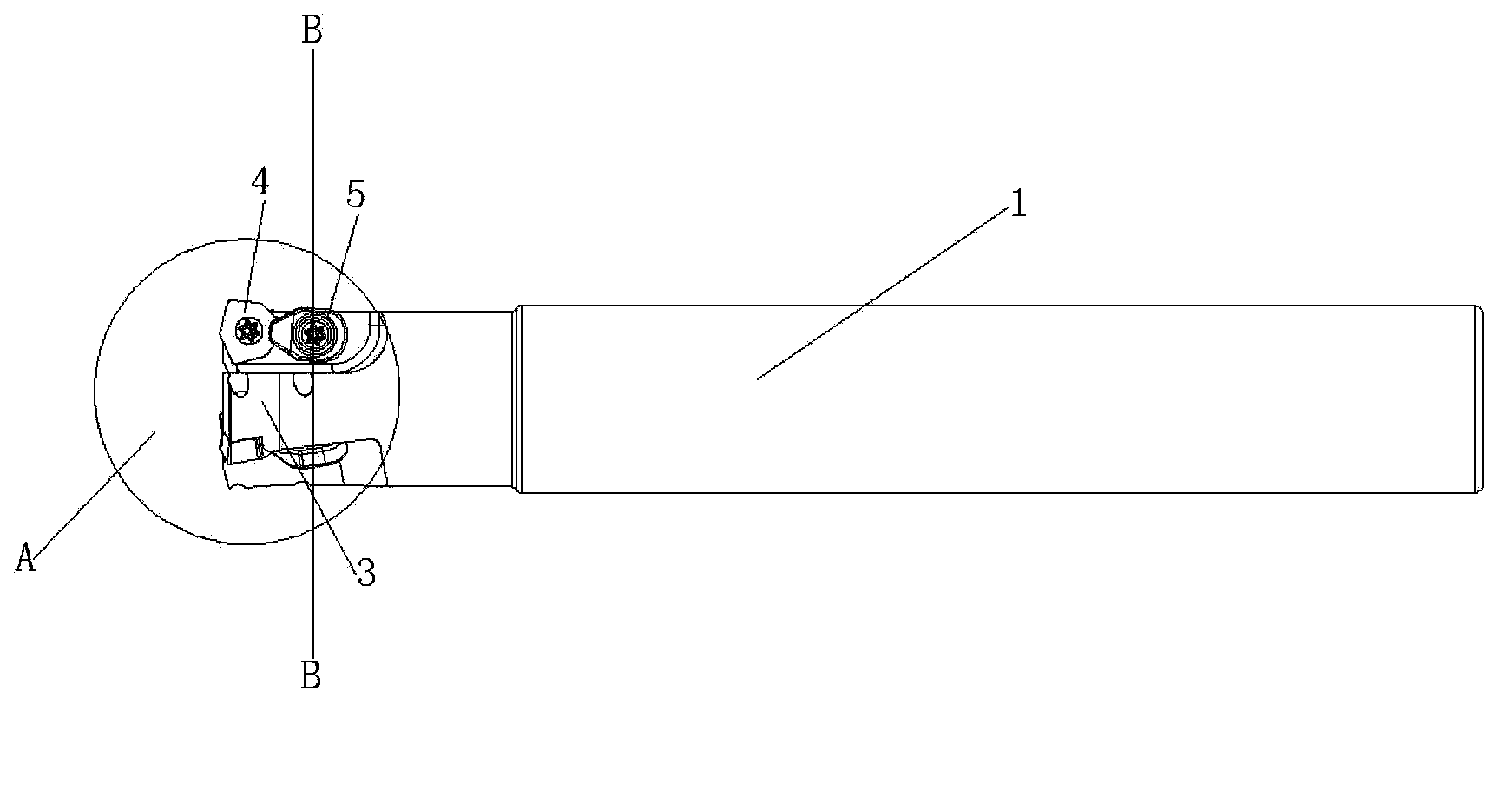

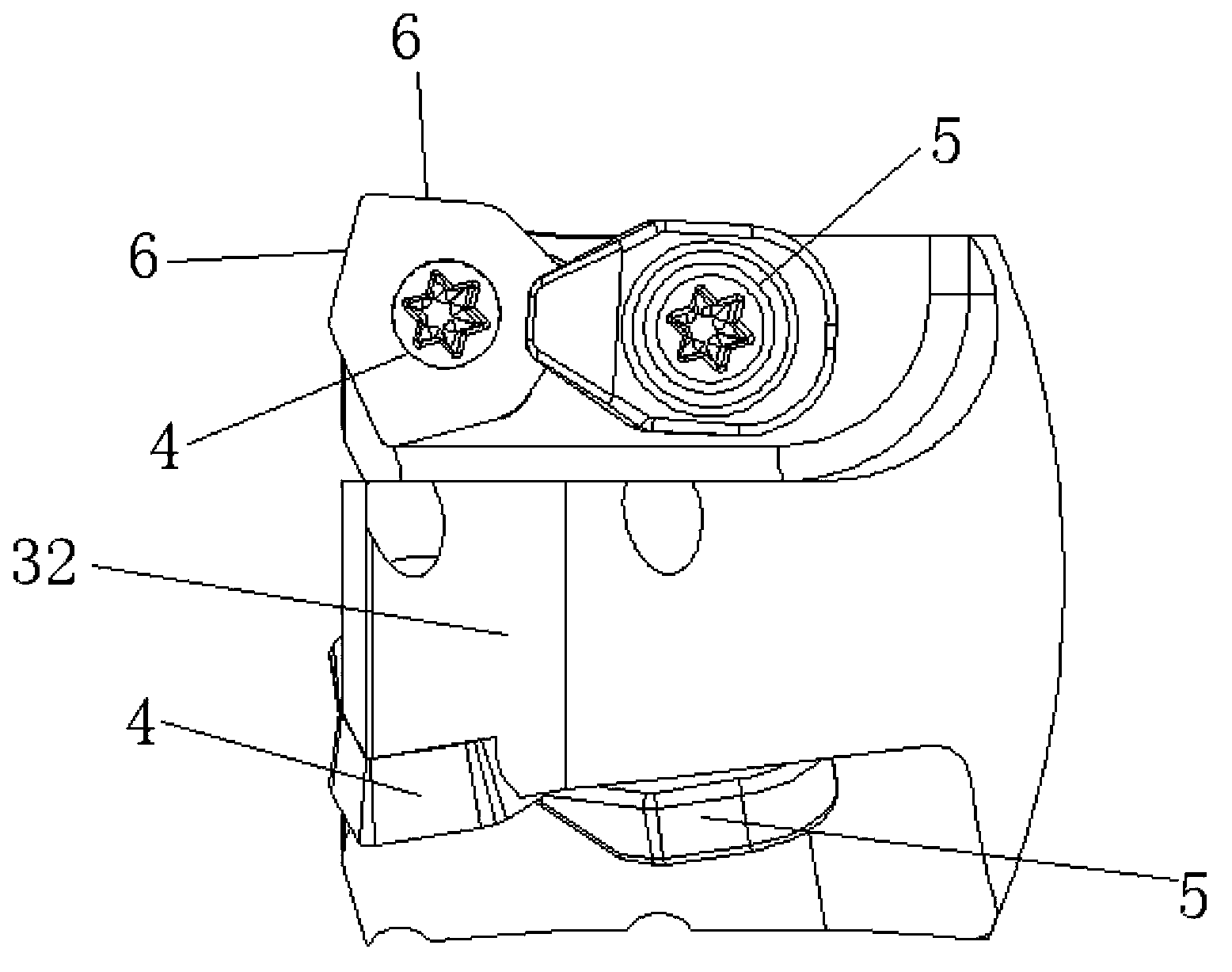

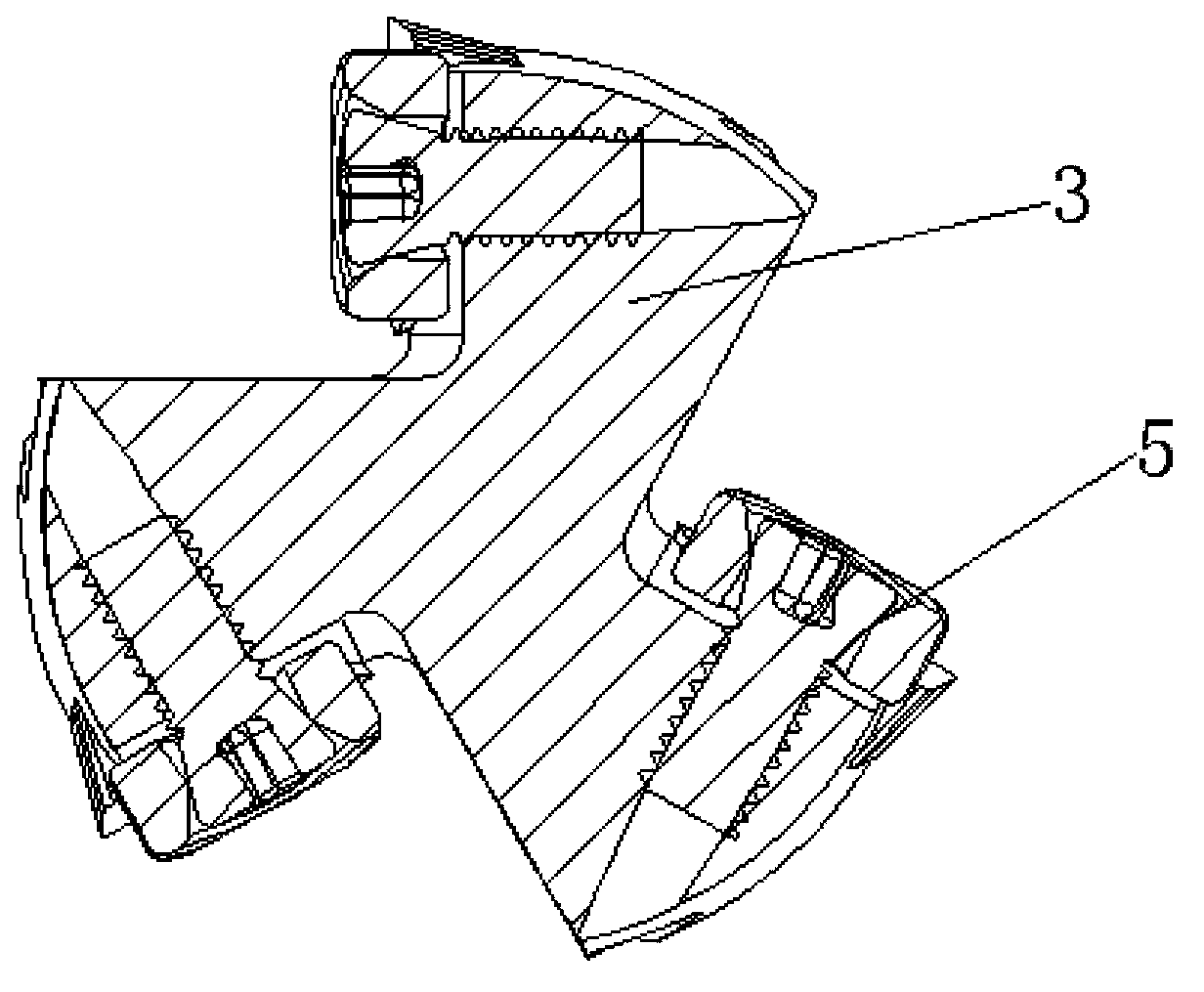

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a counter-rotating end mill includes a cylindrical shank 1, a plurality of grooves 2 are arranged at intervals around one end of the shank, and a ridge 3 is formed between two adjacent grooves. The axial direction of the shank is at a certain helical angle to the ridge, and the helical direction of the ridge is opposite to the feed direction of the workpiece to be processed. A blade 4 and a pressing plate 5 are fixedly arranged on one side of the ridge, and the blade It consists of a number of cutting edges 6 that are connected head to tail in sequence, wherein two adjacent cutting edges protrude from the end surface 31 of the ridge and the side surface 32 respectively, and the two cutting edges are respectively in the shape of the end surface and the side surface of the ridge. At a certain angle, the pressure plate is located between the blade and the handle, and the pressure plate is part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com