Heat conduction graphite sheet and manufacturing method thereof

A heat-conducting graphite sheet and graphite technology, applied in chemical instruments and methods, film/flaky adhesives, inorganic chemistry, etc., can solve problems such as uneven heat dissipation, local overheating, and poor reliability, and achieve improved flatness and flexibility, improve bidirectional tensile properties, and overcome the effect of excessive heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

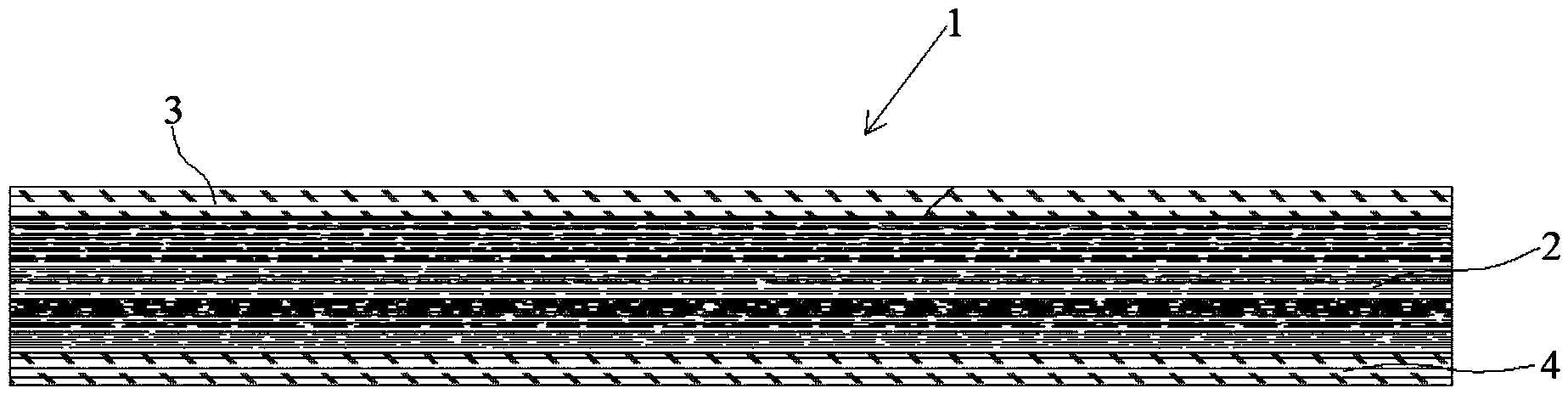

[0035] Embodiment: a kind of heat-conducting graphite sheet, described heat-conducting graphite sheet 1 is made up of polyimide film 2, first coating layer 3 and second coating layer 4, described first coating layer 3, second coating layer The cladding layer 4 is respectively located on the upper and lower surfaces of the polyimide film 2;

[0036] Both the first coating layer and the second coating layer are sintered by a graphite modifier, and the graphite modifier is composed of the following components by weight;

[0037] Described graphite modifier 4 is made up of the component of following parts by weight, as shown in table 1:

[0038] Table 1

[0039] Example 1 Example 2 Example 3 Example 4 Example 5 Benzophenone Tetradianhydride 23 22 24.5 22.5 21 Pyromellitic dianhydride 14 15 16 14.5 15.5 Diaminodiphenylmethane 23.5 25 22.5 24 24.5 dimethylformamide 20 23 24.5 22 21 N-Methylpyrrolidone 10 9 8.5 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com