Sugar-based modified polysiloxane silicone softener and preparation method thereof

A silicone softener, polysiloxane technology, applied in the direction of plant fibers, etc., can solve the problems of decreased smoothness and softening effect of fabrics, affecting the softening effect and washability, affecting the adsorption of silicone chain segments, etc., to achieve wide storage capacity. Operation temperature range and application temperature range, rapid and complete biodegradation, and the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

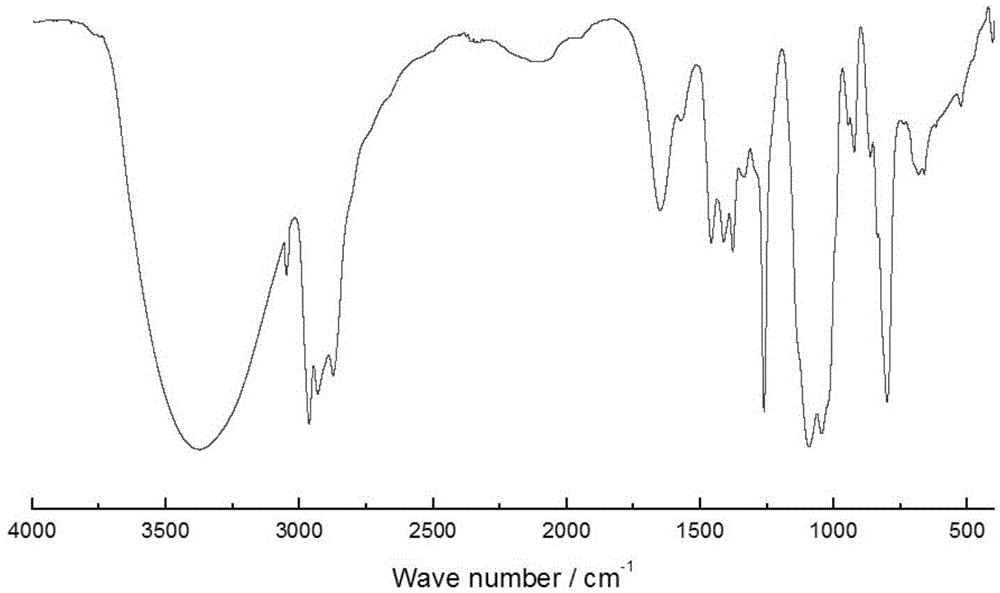

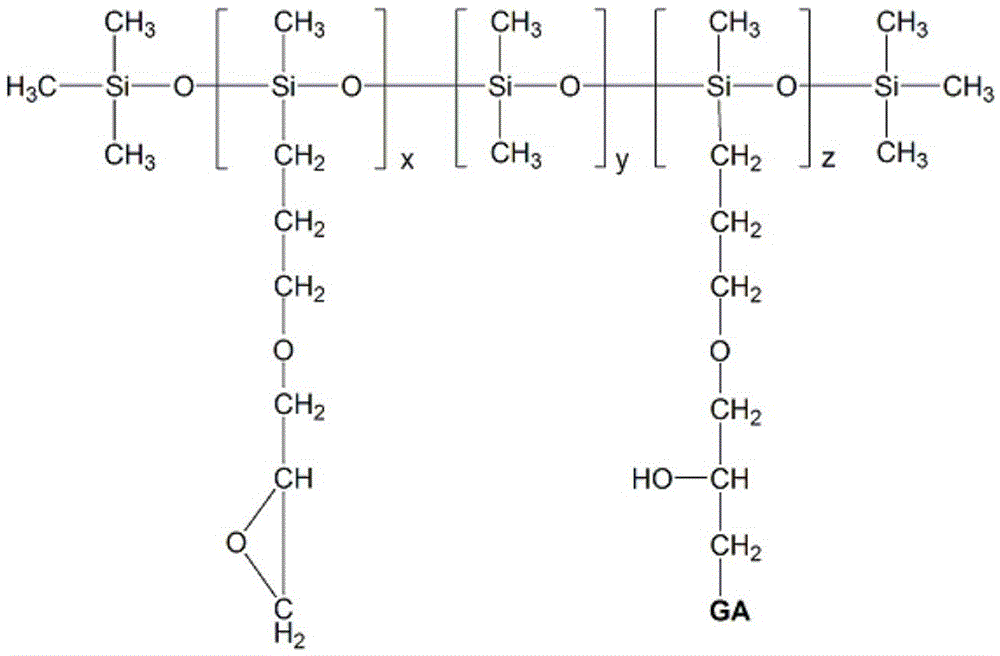

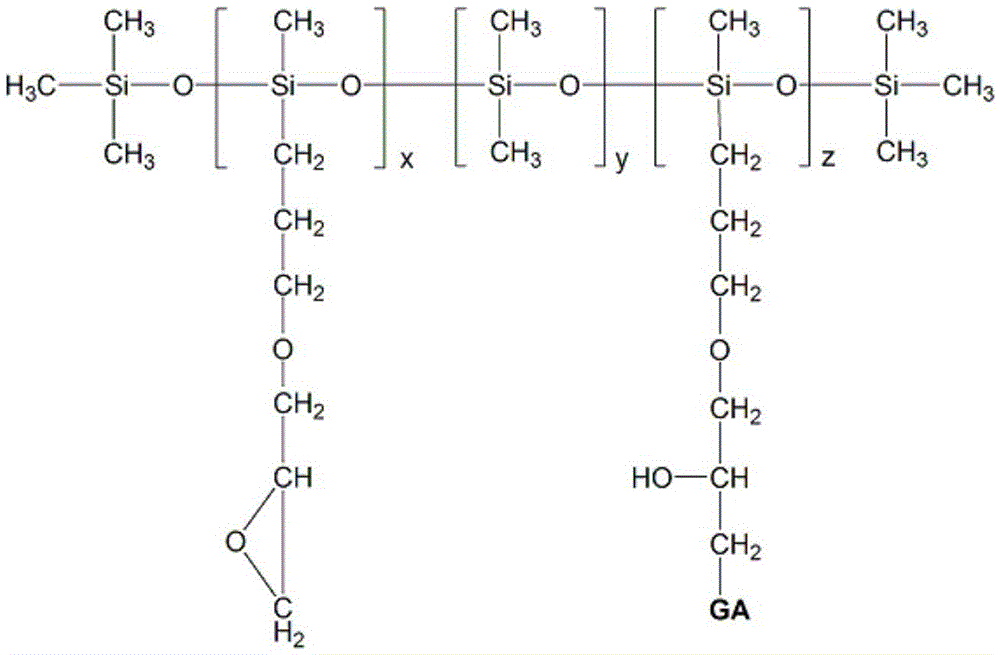

Image

Examples

preparation example Construction

[0023] The preparation method of the microemulsion type sugar-based modified polysiloxane softening agent of the present invention comprises the following steps:

[0024] (1) Preparation of epoxy-modified polysiloxane intermediate

[0025] In a four-necked flask equipped with a mechanical stirring device and a condensation reflux device, add a certain amount of water and a certain amount of nonionic surfactant composition, stir at room temperature to form a transparent aqueous solution; add an alkaline catalyst and stir to become a transparent aqueous solution; at 400 At a stirring rate of ~600rpm / min, add a certain amount of γ-glycidyl etheroxypropylmethyldialkoxysilane and octamethylcyclotetrasiloxane (D4) into the four-necked bottle successively; Stirring at a stirring rate of 800rpm / min for 10-60min to obtain a translucent emulsion system.

[0026] The above emulsion system is heated up to 60-100° C., reacted at a stirring rate of 600-800 rpm / min for 2-8 hours, and then c...

Embodiment 1

[0047] (1) Preparation of epoxy-modified polysiloxane intermediate

[0048]In a 2000ml four-neck flask equipped with a mechanical stirring device and a condensation reflux device, add a composition of 198g water and 99g APG (wherein APG121439.5g, APG161813.2g, APGi824.8g, APG0621.5g), and stir at room temperature to form a transparent aqueous solution; Add 24.75g of catalyst KOH and stir to form a transparent aqueous solution; at a stirring rate of 600rpm / min, add 49.7g of γ-glycidyl etheroxypropylmethyl diethoxysilicon and 98.0g of octamethylcyclotetrasiloxane D4198.0g successively Add it into a four-neck flask; stir for 60 min at a stirring rate of 800 rpm / min to obtain an emulsion system.

[0049] The above emulsion system was heated up to 95° C., reacted at a stirring rate of 800 rpm / min for 8 hours, and then cooled to room temperature to obtain an alkoxy-modified polysiloxane intermediate emulsion.

[0050] (2) Preparation of sugar-based modified polysiloxane softener

...

Embodiment 2

[0061] (1) Preparation of epoxy-modified polysiloxane intermediate

[0062] In a 3000ml four-neck flask equipped with a mechanical stirring device and a condensing reflux device, add a composition of 1191.3g water and 45.1g APG (wherein APG0812.2g, APG121432.9g), and stir at room temperature to form a transparent aqueous solution; add catalyst C 2 h 5 OK7.7g was stirred to become a transparent aqueous solution; at a stirring rate of 600rpm / min, 5.0g of γ-glycidyl etheroxypropylmethyl dimethoxysilane and 6.6g of octamethylcyclotetrasiloxane D4296 were successively added to four In a mouth bottle; Stir at a stirring rate of 800rpm / min for 20min to obtain a translucent emulsion system.

[0063] The above emulsion system was heated up to 90° C., reacted at a stirring rate of 800 rpm / min for 4 hours, and then cooled to room temperature to obtain a translucent emulsion of an alkoxy-modified polysiloxane intermediate.

[0064] (2) Preparation of sugar-based modified polysiloxane so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com