A high-strength and low-stretch bio-based fiber fabric and its preparation method

A high-strength, low-stretch, bio-based technology, applied in the field of textile manufacturing, can solve problems such as poor anti-pilling effect, low bursting strength of fabrics, and hard hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0142]A method for preparing a high-strength and low-stretch bio-based fiber fabric, including the following steps:

[0143](1) Preparation of yarn

[0144](2) Weaving grey cloth

[0145]The yarn obtained in step (1) is woven in a plain weave to obtain a grey cloth for use;

[0146](3) Dyeing and finishing

[0147]A. Pre-formation: pre-form the grey fabric prepared in step (2) at a temperature of 180°C and a relative humidity of 50%; in the pre-formation machine, the vehicle speed is 10m / min;

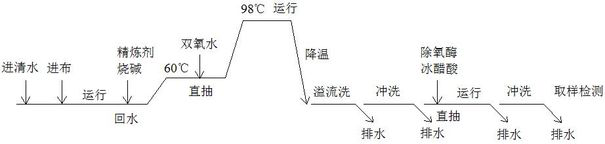

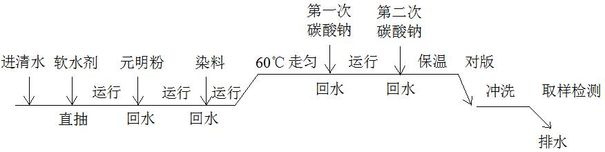

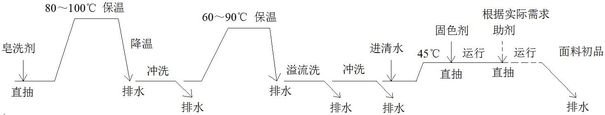

[0148]B. Pretreatment

[0149]Pour clear water into the dye vat, arrange the pre-shaped blanks into the dye vat, and run for 5 min; add refining agent and caustic soda to the auxiliary vat, and after the dissolution is uniform, return the water to the dye vat within 1 min. The cycle period is 8 min;

[0150]Increase the temperature in the dyeing vat to 60℃ at 2℃ / min, add hydrogen peroxide to the auxiliary vat, dissolve it evenly, pump it directly into the dyeing vat for 2min; then heat up the dye vat to 98℃ at 2℃ / mi...

Embodiment 2

[0163]A method for preparing a high-strength and low-stretch bio-based fiber fabric, including the following steps:

[0164](1) Preparation of yarn

[0165](2) Weaving grey cloth

[0166]The yarn obtained in step (1) is woven in a plain weave to obtain a grey cloth for use;

[0167](3) Dyeing and finishing

[0168]A. Pre-formation: pre-form the grey fabric prepared in step (2) at a temperature of 200°C and a relative humidity of 50-90%; in the pre-formation machine, the vehicle speed is 30m / min;

[0169]B. Pretreatment

[0170]Pour clean water into the dye vat, arrange the pre-shaped blanks into the dye vat, and run for 10 min; add refining agent and caustic soda to the auxiliary vat, and after the dissolution is uniform, return the water to the dye vat in 2 min with a cycle period of 10 min;

[0171]Increase the temperature in the dyeing vat to 60℃ at 2℃ / min, add hydrogen peroxide to the auxiliary vat and dissolve it evenly, then pump it directly into the dye vat for 3min; then increase the temperature in...

Embodiment 3

[0184]A method for preparing a high-strength and low-stretch bio-based fiber fabric, including the following steps:

[0185](1) Preparation of yarn

[0186](2) Weaving grey cloth

[0187]The yarn obtained in step (1) is woven in a plain weave to obtain a grey cloth for use;

[0188](3) Dyeing and finishing

[0189]A. Pre-formation: pre-form the grey fabric prepared in step (2) at a temperature of 185°C and a relative humidity of 60%; in the pre-formation machine, the vehicle speed is 15m / min;

[0190]B. Pretreatment

[0191]Pour clean water into the dye vat, arrange the pre-shaped blanks into the dye vat, and run for 6 min; add refining agent and caustic soda to the auxiliary vat, and after the dissolution is uniform, return the water to the dye vat in 2 min with a cycle period of 8.5 min;

[0192]Increase the temperature in the dyeing vat to 60℃ at 2℃ / min, add hydrogen peroxide to the auxiliary vat and dissolve it evenly, then pump it directly into the dye vat for 3min; then heat the dye vat to 98℃ at 2℃ / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com