Antibacterial heat insulation reflective coating and preparation method thereof

A technology of reflective coatings and heat insulation, applied in the field of coatings, can solve the problems of poor flexibility, compactness and adhesion of coatings, no antibacterial effect, unsuitable for coating, etc., and achieve good heat insulation effect, good antibacterial effect, and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An antibacterial heat-insulating reflective coating, comprising the following components in parts by weight: 40 parts of silicon-acrylic emulsion, 2 parts of nano-titanium dioxide, 1 part of nano-zinc oxide, 1 part of zinc pyrithione, 6 parts of vermiculite, sepiolite 5 parts, 4 parts of organic bentonite, 0.5 parts of dispersant 5040, 0.5 parts of mineral oil defoamer, 18 parts of water.

[0018] The preparation method of the antibacterial heat-insulating reflective coating of the present embodiment comprises the following steps:

[0019] Step (1): Grinding vermiculite, sepiolite and organic bentonite to 120-200 mesh;

[0020] Step (2): Add silicone acrylic emulsion into water, then add dispersant 5040 and mineral oil defoamer to it, stir until well mixed, then add ground vermiculite, sepiolite and organic bentonite in step (1) , continue stirring to obtain slurry;

[0021] Step (3): Add nano-titanium dioxide, nano-zinc oxide and zinc pyrithione into the slurry in st...

Embodiment 2

[0023] An antibacterial heat-insulating reflective coating, comprising the following components in parts by weight: 55 parts of silicon-acrylic emulsion, 4 parts of nano-titanium dioxide, 2 parts of nano-zinc oxide, 3 parts of zinc pyrithione, 9 parts of vermiculite, sepiolite 12 parts, 7 parts of organic bentonite, 1 part of dispersant 5040, 2 parts of mineral oil defoamer, 30 parts of water.

[0024] The preparation method of the antibacterial heat-insulating reflective coating of this embodiment is the same as the preparation method of embodiment 1.

Embodiment 3

[0026] An antibacterial heat-insulating reflective coating, comprising the following components in parts by weight: 48 parts of silicon-acrylic emulsion, 3.1 parts of nano-titanium dioxide, 1.6 parts of nano-zinc oxide, 2 parts of zinc pyrithione, 8 parts of vermiculite, sepiolite 9 parts, 5 parts of organic bentonite, 0.9 parts of dispersant 5040, 1.2 parts of mineral oil defoamer, 26 parts of water.

[0027] The preparation method of the antibacterial heat-insulating reflective coating of this embodiment is the same as the preparation method of embodiment 1.

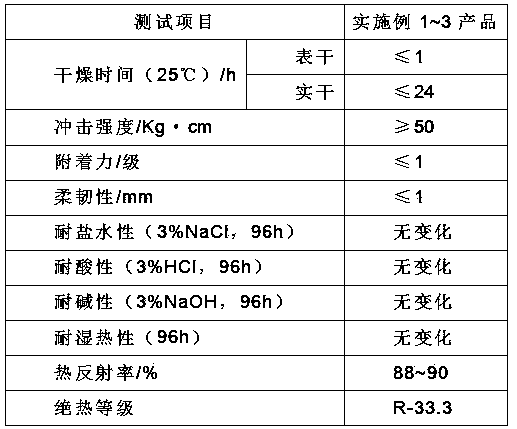

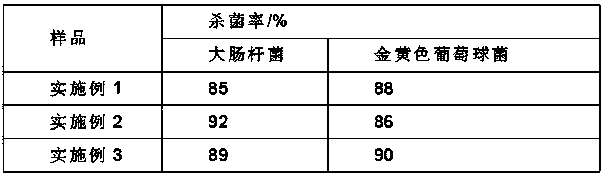

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com