Solid-free active salt water drilling fluid for coalbed methane (CBM) horizontal wells

A brine drilling fluid and horizontal well technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of no production, wellbore cleanliness and wellbore stability, and wellbore collapse, etc., to achieve improved the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The formula of the brine drilling fluid provided by the present invention is: water+1.0% water-based lubricant+0.5% waterproof locking agent, adjust its density to 1.15g / cm with industrial sodium chloride 3 ;

[0022] Preparation process: Take an appropriate amount of water, add 1.0% water-based lubricant under stirring conditions, and add industrial sodium chloride after fully dissolving to adjust its density to 1.15g / cm 3 , and finally add 0.5% waterproof locking agent, fully dissolved and placed for 2 hours.

[0023] Performance measurement: according to "GB / T16783.1-2006 Oil and Gas Industry Drilling Fluid Field Test Part 1 Water-based Drilling Fluid".

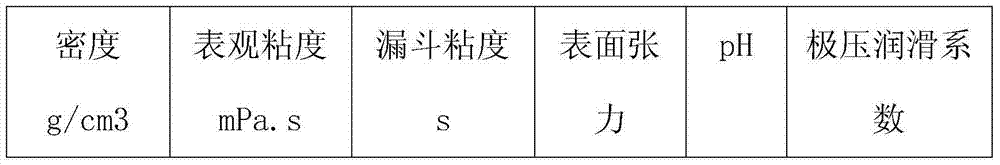

[0024] Drilling fluid properties: Table 1 shows the properties of the solid-free active brine drilling fluid prepared in Example 1 (surface tension is measured at room temperature).

[0025] Table 1: Drilling Fluid Properties

[0026]

[0027]

Embodiment 2

[0029] The formula of the brine drilling fluid provided by the present invention is: water+2.0% water-based lubricant+0.5% waterproof locking agent, adjust its density to 1.10g / cm with industrial potassium chloride 3 ;

[0030] Preparation process: Take an appropriate amount of water, add 2.0% water-based lubricant under stirring conditions, and add industrial potassium chloride after fully dissolving to adjust its density to 1.10g / cm 3 , and finally add 0.5% waterproof locking agent, fully dissolved and placed for 2 hours.

[0031] Performance measurement: according to "GB / T16783.1-2006 Oil and Gas Industry Drilling Fluid Field Test Part 1 Water-based Drilling Fluid".

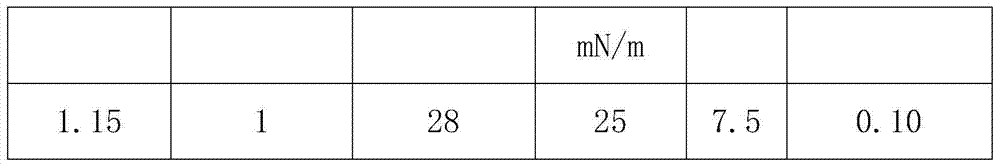

[0032] Drilling fluid properties: Table 2 shows the properties of the solid-free active brine drilling fluid prepared in Example 2 (surface tension is measured at room temperature).

[0033] Table 2: Drilling Fluid Properties

[0034]

Embodiment 3

[0036] The formula of the brine drilling fluid provided by the present invention is: water+3.0% water-based lubricant+1.0% waterproof locking agent, adjust its density to 1.35g / cm with industrial calcium chloride 3 ;

[0037] Preparation process: Take an appropriate amount of water, add 3.0% water-based lubricant under stirring conditions, add industrial calcium chloride after fully dissolving to adjust its density to 1.35g / cm 3 , and finally add 1.0% waterproof locking agent, fully dissolved and left for 2 hours.

[0038] Performance measurement: according to "GB / T16783.1-2006 Oil and Gas Industry Drilling Fluid Field Test Part 1 Water-based Drilling Fluid".

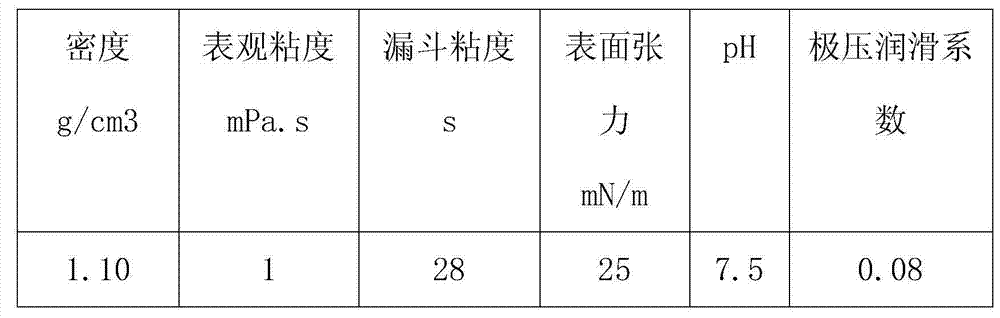

[0039] Drilling fluid properties: Table 3 shows the properties of the solid-free active brine drilling fluid prepared in Example 3 (surface tension is measured at room temperature).

[0040] Table 3 Drilling Fluid Properties

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com