Saccharomyces cerevisiae strain and green plum fruit wine prepared by using saccharomyces cerevisiae strain

A technology of Saccharomyces cerevisiae strain and green plum fruit wine, which is applied in the preparation of alcoholic beverages, fungi, biochemical equipment and methods, etc., to achieve the effect of enriching nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

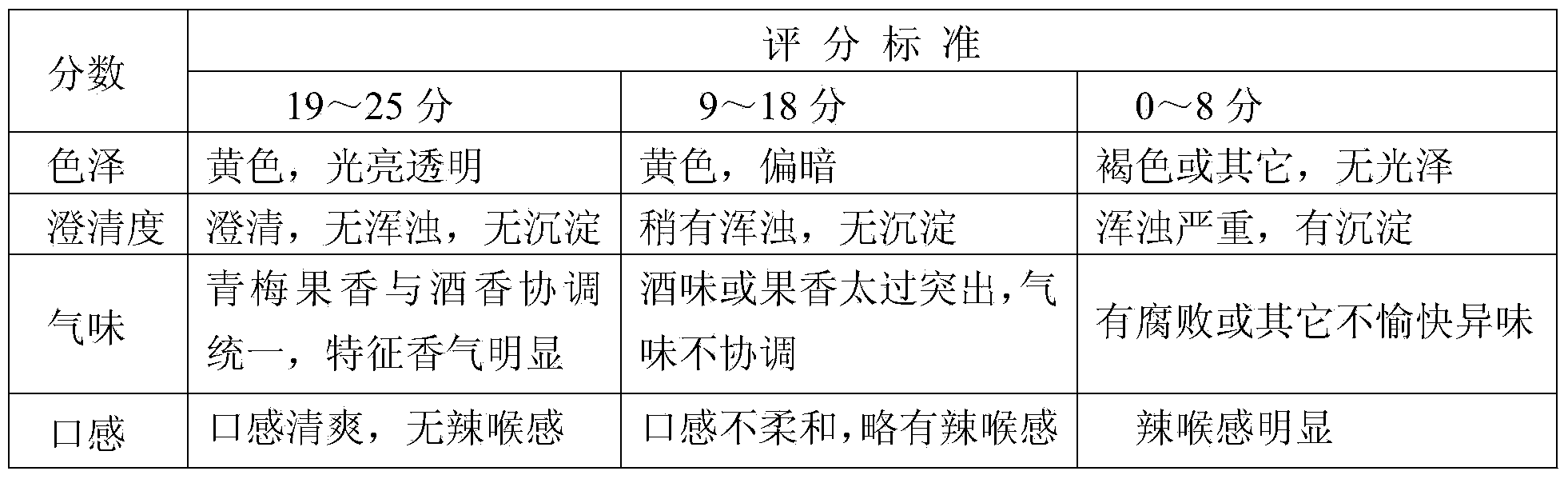

Examples

Embodiment 1

[0039] Embodiment 1: (preparation of green plum fruit wine 1)

[0040] (1) Preparation and processing of greengage pulp: select nine mature (yellow-red, soft flesh) greengage fruits, rinse with clean water, drain the water, remove the core and beat, add 300U / mL pectinase and 1000U / mL fiber to the obtained pulp Sulfase, 45°C constant temperature enzymatic hydrolysis for 3 hours, filtered through a 200-mesh filter cloth, took the filtrate, diluted 8 times with water, added sucrose to 350g / L, adjusted the pH value to 5.5, and set aside;

[0041] (2) Pre-fermentation of green plum wine: Inoculate S. cerevisiae QM5236 into plum juice medium, culture for 48 hours, then insert the inoculum amount of 3mL / L into the pulp treatment solution in step (1) for submerged fermentation. At 20°C, culture for 15 days until no obvious bubbles overflow from the liquid surface, then transfer the clarified fermentation liquid in the upper layer to a sterile container;

[0042] (3) Post-fermentation...

Embodiment 2

[0044] Embodiment 2: (green plum fruit wine preparation 2)

[0045] In this example, add 1500U / mL pectinase and 250U / mL cellulase to green plum pulp in step (1), take the filtrate after enzymatic hydrolysis and filtration, dilute it twice with water, add sucrose to 160g / L, and adjust the pH value to 4.5, standby; after activated S.cerevisiae QM5236 in plum juice medium in step (2), inoculate at an inoculum volume of 15mL / L, culture at 30°C for 3 days until no obvious bubbles overflow the liquid surface, then transfer the upper layer Supernatant liquid; the fermented liquid transferred in step (3) is placed at 30°C, fermented for 7 days, and when the sugar content of the fermented liquid does not change significantly, the supernatant liquid is transferred again; in step (4), the green plum fruit wine in step (3) is sealed , aged at 20°C for 30 days in a dark and cool place, sterilized at 65°C for 30 minutes, filled and sealed, and then it was greengage fruit wine. Others are t...

Embodiment 3

[0046] Embodiment 3: (preparation of green plum fruit wine 3)

[0047] In this example, add 750U / mL pectinase and 500U / mL cellulase to green plum pulp in step (1), enzymatically hydrolyze and filter, take the filtrate, dilute it 4 times with water, add sucrose to 280g / L, and adjust the pH value to 5.0, set aside; in step (2), activate S.cerevisiae QM5236 in plum juice medium, inoculate at an inoculum volume of 7 mL / L, and incubate at 25°C for 7 days until there are no obvious bubbles overflowing the liquid surface, then transfer the upper layer Supernatant liquid; the fermented liquid transferred in step (3) is placed at 25°C and fermented for 10 days until there is no significant change in the sugar content of the fermented liquid, then transfer the supernatant liquid again; in step (4), seal the original greengage wine in step (3) , aged at 15°C for 45 days in a dark and cool place, sterilized at 70°C for 25 minutes, filled and sealed, and then it was greengage fruit wine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com