A method of using a static cracking agent for pile cutting in construction

A static cracking agent and construction technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as easy to cause a lot of concrete fragments, harmful to pile workers, and noisy crushing process, so as to reduce machine and labor The effect of investment, cost saving and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] A kind of static cracking agent used for cutting piles in construction. The preparation method of the static cracking agent is as follows: firstly, limestone calcium carbonate of different sizes is calcined through a calciner at a high temperature of 2000 degrees for 72 hours, and after calcination for 72 hours, it is taken out and cooled. After being crushed into granules with a size of 8-12mm by a crusher, the granules are packed to form a strip-shaped static cracking agent with a length of 600-800mm and a width of 60-80mm.

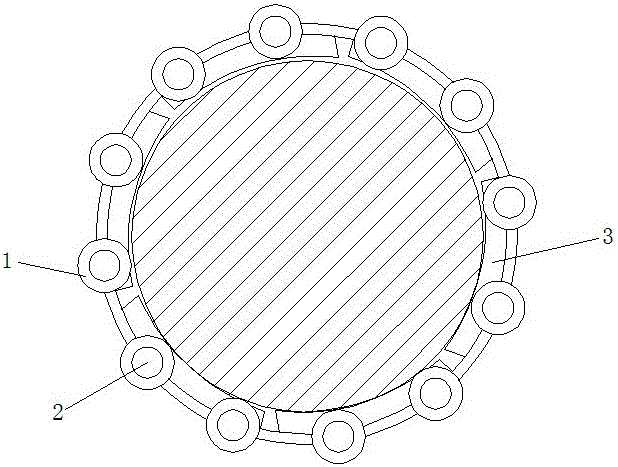

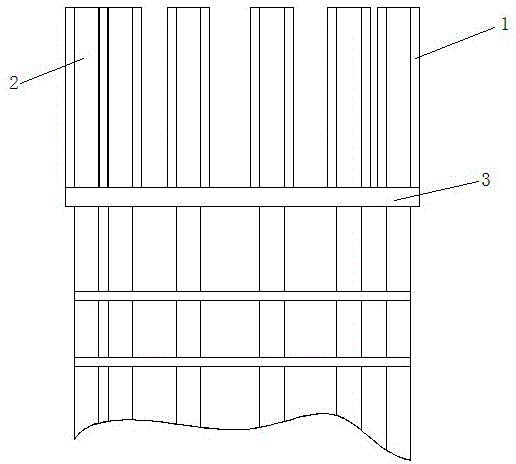

[0016] Such as figure 1 , figure 2 As shown, a method of using a static cracking agent for building cut piles, it first puts the polystyrene foam tube 1 on the steel bar 2 of the pile head, so that the steel bar 2 can be separated from the cement to prevent it from bonding, Then install strip static cracking agent 3 at the cutting place of the pile head, pour the cement concrete into the pile and bury the pile, and the strip static cracking age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com