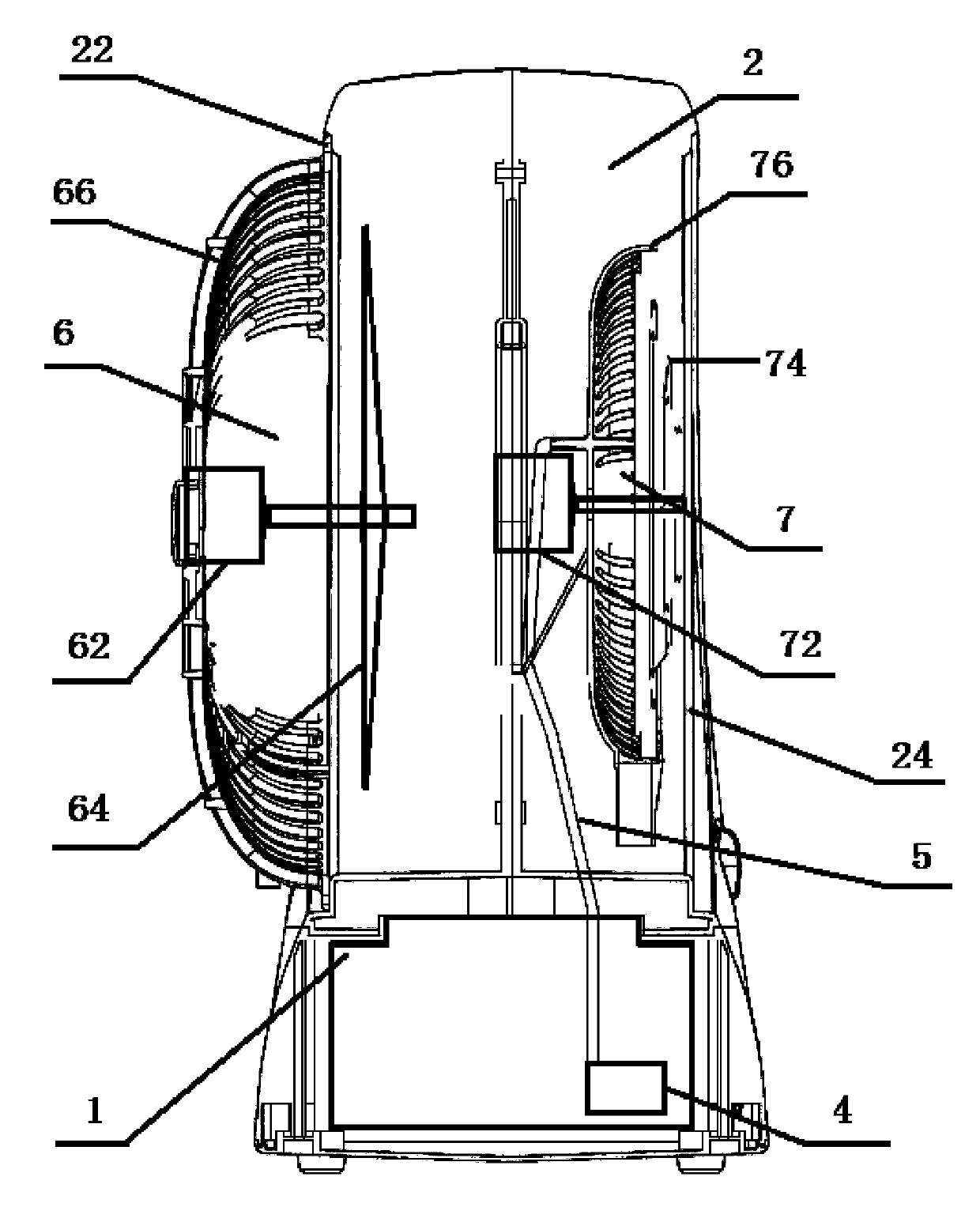

Centrifugal spraying fan comprising ultralow safe voltage motor

A technology of centrifugal spray and safe voltage, applied in the field of electric fans, can solve the problems of poor portability, reduced spray effect, and difficulty in providing long-term continuous water mist from aerosol cans, so as to achieve the effect of easy movement and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020]The damping and shock-absorbing matrix described in this embodiment is made of a composite material of resin and inorganic material; it contains 18.0wt% of MDI, 3.0wt% of hydroxyl-terminated polybutadiene (Polybd brand R-15HT of CrayValley Company), 1.2wt% of trimethylolpropane, 2.2wt% of benzoic acid-2-hydroxyethyl ester, 5.0wt% of vinyltrimethoxysilane, 32.0wt% of diglycidyl acrylate, and the balance of three Aluminum oxide (average particle size 20μm). The preparation method of the damping and shock-absorbing matrix is as follows: Weigh the components according to the proportion, mix and disperse the components except MDI, then add the MDI, stir and mix evenly, cast and solidify, and then pour and solidify at 120 ℃, curing 50min.

Embodiment 2

[0022] The damping and shock-absorbing matrix is made of a composite material of resin and inorganic material; it contains 20.0wt% of MDI, 2.5wt% of hydroxyl-terminated polybutadiene (Polybd grade R-15HT of CrayValley Company), 1.5wt% Trimethylolpropane, 2.0wt% benzoic acid-2-hydroxyethyl ester, 4.0wt% vinyltrimethoxysilane, 28.0wt% diglycidyl acrylate and the balance of aluminum oxide ( Average particle size 20μm). The preparation method of the damping and shock-absorbing matrix is as follows: Weigh the components according to the proportion, mix and disperse the components except MDI, then add the MDI, stir and mix evenly, cast and solidify, and then pour and solidify at 120 ℃, curing 50min.

Embodiment 3

[0036] The water-resistant protective layer is formed on the base of the fan blade with a thickness of 200 μm. It is made of 20.5wt% MDI, 13.5wt% hydroxyl-terminated styrene-butadiene liquid rubber (produced by Shandong Zibo Qilong Chemical Co., Ltd., type II), 4.2 wt% of PTMG1000, 1.8wt% of 1,4-butanediol, 1.2wt% of ethoxylated bisphenol F diacrylate, 1.5wt% of vinyltriethoxysilane, 0.15wt% of defoamer BYK -028, 0.15wt% leveling agent BYK-346, 0.20wt% dibutyltin dilaurate, 8.5wt% titanium dioxide (average particle size 10μm), 9.0wt% dimethyl carbonate and the rest Stir ethyl acetate at a stirring speed of 300-400 rpm for 30 minutes to obtain a polyurethane prepolymer, and then prepare and dry the polyurethane prepolymer by casting or coating to obtain the water-resistant protective layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com