Water-dispersible acrylic adhesive composition and adhesive sheet

An acrylic, dispersive technology, applied in the direction of non-polymer adhesive additives, adhesive types, conductive adhesives, etc., can solve the problems of pollution, not yet obtained re-peelability, etc., to achieve low pollution, appearance characteristics The effect of excellent, excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

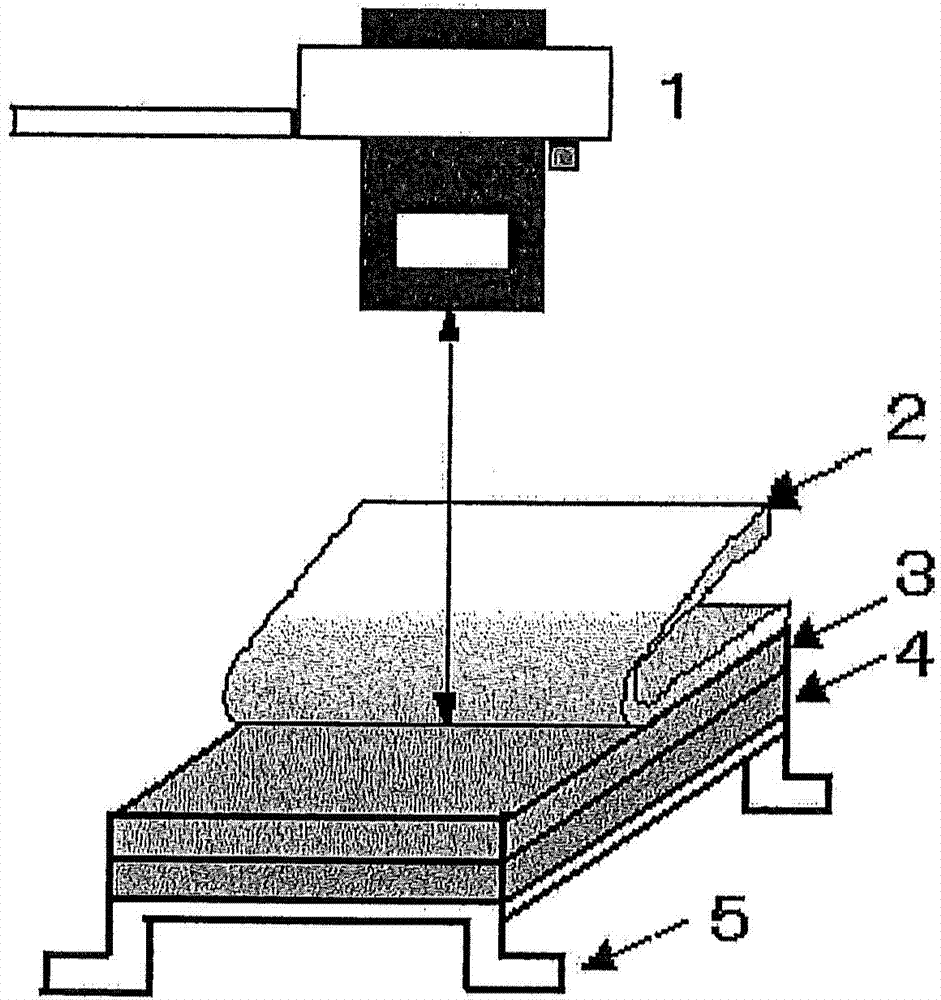

Image

Examples

Embodiment 1

[0256] (Preparation of Acrylic Emulsion Polymer)

[0257] 90 parts by weight of water, 96 parts by weight of 2-ethylhexyl acrylate (2EHA), 4 parts by weight of acrylic acid (AA), and a reactive nonionic anionic emulsifier (manufactured by ADEKA Co., Ltd.) are mixed in the container. , trade name "Adecariasorp SE-10N") 3 parts by weight, and then stirred and mixed with a high-speed mixer to prepare a monomer emulsion.

[0258] Then, 50 parts by weight of water, 0.01 part by weight of a polymerization initiator (ammonium persulfate) and an amount equivalent to 10% by weight in the aforementioned monomer emulsion were added to a reaction vessel having a condenser tube, a nitrogen gas introduction tube, a thermometer, and a stirrer, Emulsion polymerization was carried out at 75° C. for 1 hour while stirring. Then, 0.07 parts by weight of a polymerization initiator (ammonium persulfate) was further added, and the remaining whole monomer emulsion (an amount corresponding to 90% by ...

Embodiment 2~8、 comparative example 1~5

[0264] As shown in Tables 1 and 2, monomer emulsions were prepared in the same manner as in Example 1, changing the types and compounding amounts of the raw material monomers and ionic liquids, and the like. In addition, additives not described in the table were prepared in the same compounding quantities as in Example 1. Moreover, using the said monomer emulsion, it carried out similarly to Example 1, and obtained the water dispersion type acrylic adhesive composition and the adhesive sheet.

[0265] [Evaluation]

[0266] The water-dispersible acrylic pressure-sensitive adhesive compositions and pressure-sensitive adhesive sheets obtained in Examples and Comparative Examples were evaluated by the following measurement methods or evaluation methods. In addition, the evaluation results are shown in Tables 1 and 2.

[0267] (1) Stripping electrostatic voltage

[0268] The prepared adhesive sheet was cut into a size of 70 mm in width and 130 mm in length, and after the separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com