Removable water-dispersible acrylic-based adhesive composition and adhesive sheet

An acrylic, dispersion-type technology, applied in the direction of acidic copolymer adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the difficult to meet the requirements of surface protection film improvement, and has not yet achieved re-peelability, etc. problem, to achieve the effect of excellent anti-whitening pollution, excellent anti-static performance, and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

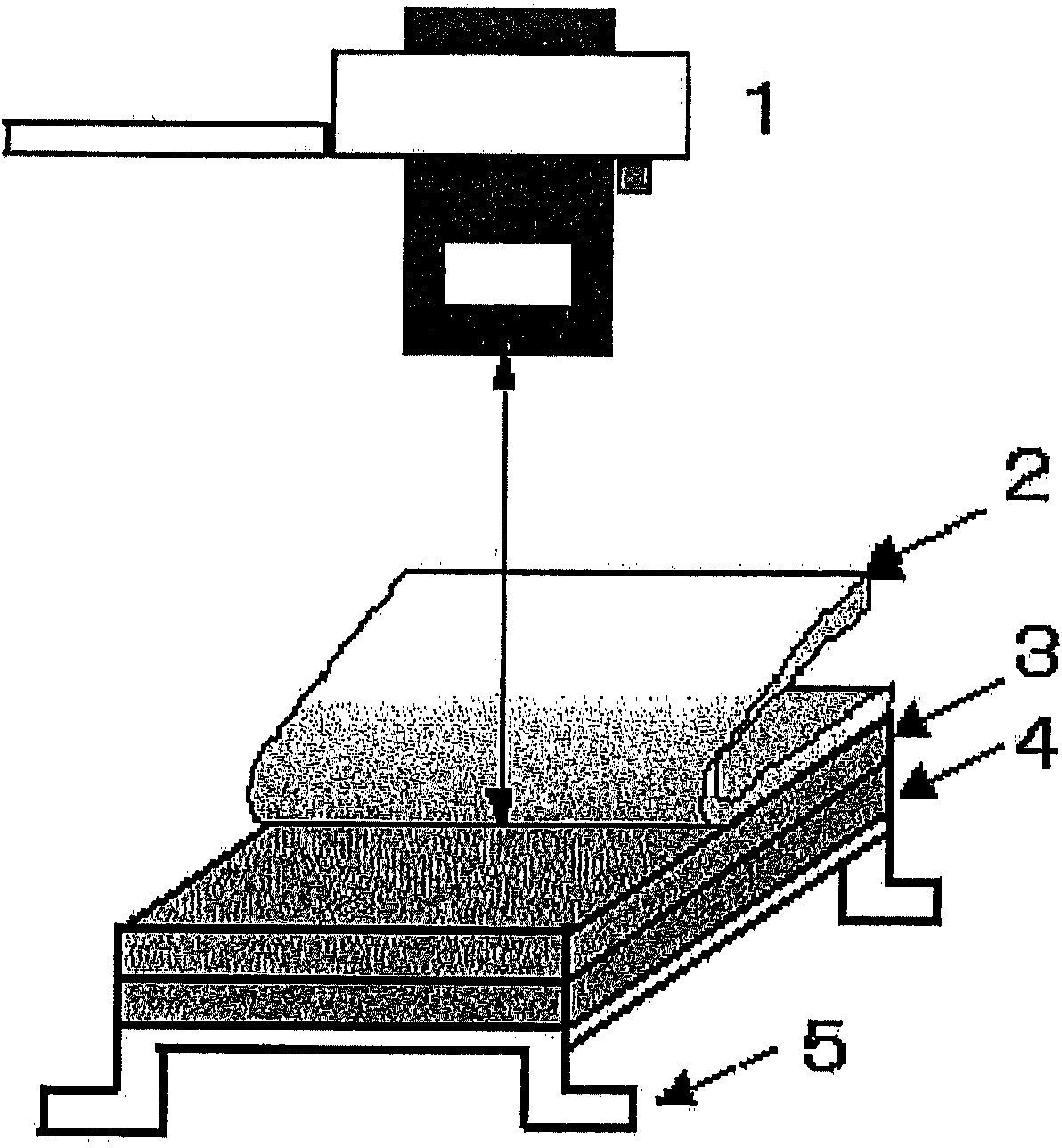

Image

Examples

Embodiment 1-1

[0236] (Preparation of Acrylic Emulsion Polymer)

[0237] Mix 90 parts by weight of water, 96 parts by weight of 2-ethylhexyl acrylate (2EHA), 4 parts by weight of acrylic acid (AA) as shown in Table 1, and a reactive nonionic anionic emulsifier (Daiichi Kogyo Pharmaceutical Co., Ltd. Co., Ltd., trade name "Aquaron HS-1025") 3 parts by weight, and then stirred and mixed with a high-speed mixer to prepare a monomer emulsion.

[0238] Then, 50 parts by weight of water, 0.01 part by weight of a polymerization initiator (ammonium persulfate) and an amount corresponding to 10% by weight of the monomer emulsion were added to a reaction vessel with a condenser tube, a nitrogen gas introduction tube, a thermometer and a stirrer. , emulsion polymerization was carried out at 65° C. for 1 hour while stirring. Then, 0.05 parts by weight of a polymerization initiator (ammonium persulfate) was further added, and the remaining whole monomer emulsion (an amount corresponding to 90% by weight...

Embodiment 1-2~1-10

[0243]

[0244] As shown in Table 1, a monomer emulsion was prepared in the same manner as in Example 1-1, changing the raw material monomers and compounding amounts, and the like. In addition, additives not described in the table were prepared in the same compounding quantities as in Example 1-1. In addition, using the monomer emulsion, a re-peelable water-dispersed acrylic pressure-sensitive adhesive composition and a pressure-sensitive adhesive sheet were obtained in the same manner as in Example 1-1.

[0245] [evaluate]

[0246] The re-peelable water-dispersed acrylic pressure-sensitive adhesive compositions and pressure-sensitive adhesive sheets obtained in Examples and Comparative Examples were evaluated by the following measurement methods or evaluation methods. In addition, the evaluation results are shown in Table 1.

[0247]

[0248] The prepared adhesive sheet was cut into a size of 70 mm in width and 130 mm in length, and after the separator was peeled off, i...

Embodiment 2-1

[0279] (Preparation of Acrylic Emulsion Polymer)

[0280] Mix 90 parts by weight of water, 92 parts by weight of 2-ethylhexyl acrylate (2EHA) as shown in Table 2, 4 parts by weight of acrylic acid (AA), and 4 parts by weight of methyl methacrylate (MMA) in the container. 3 parts by weight of a nonionic anionic emulsifier (manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd., trade name "Aquaron HS-1025"), and then stirred and mixed with a high-speed mixer to prepare a monomer emulsion.

[0281] Then, 50 parts by weight of water, 0.01 part by weight of a polymerization initiator (ammonium persulfate) and an amount corresponding to 10% by weight of the monomer emulsion were added to a reaction vessel with a condenser tube, a nitrogen gas introduction tube, a thermometer and a stirrer. , emulsion polymerization was carried out at 65° C. for 1 hour while stirring. Then, 0.05 parts by weight of a polymerization initiator (ammonium persulfate) was further added, and the remaining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com