Water-dispersible acrylic pressure-sensitive adhesive composition, pressure-sensitive adhesive layer, and pressure-sensitive adhesive sheet

一种丙烯酸、分散型的技术,应用在非高分子粘合剂添加剂、酸性共聚物粘合剂、聚醚粘合剂等方向,能够解决污染、尚未得到外观特性和再剥离性水分散型丙烯酸类粘合剂等问题,达到低污染性、优良外观特性、优良防静电性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

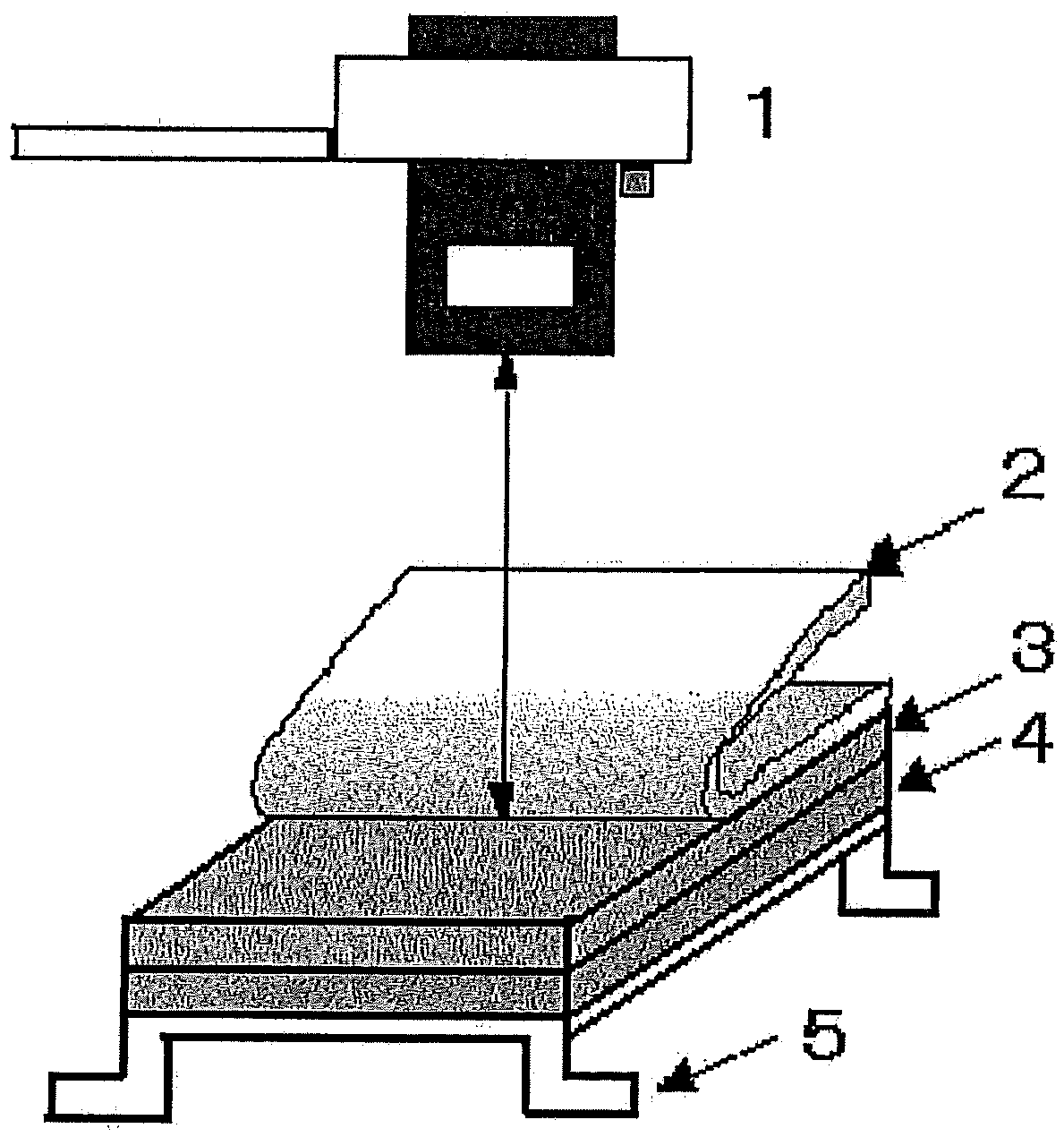

Image

Examples

Embodiment 1-1

[0310] (Preparation of Acrylic Emulsion Polymer)

[0311] Mix 90 parts by weight of water in the container, and 94 parts by weight of 2-ethylhexyl acrylate (2EHA) as shown in Table 1, 2 parts by weight of methyl methacrylate (MMA), 4 parts by weight of acrylic acid (AA), react 6 parts by weight of a nonionic anionic emulsifier (manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd., trade name "Aquaron HS-10"), and then stirred and mixed with a high-speed mixer to prepare a monomer emulsion. Then, 50 parts by weight of water, 0.01 part by weight of a polymerization initiator (ammonium persulfate) and 10% by weight of the monomer emulsion prepared above are added to a reaction vessel having a condenser tube, a nitrogen introduction tube, a thermometer and an agitator. amount, emulsion polymerization was carried out at 75° C. for 1 hour while stirring. Thereafter, 0.07 parts by weight of a polymerization initiator (ammonium persulfate) was added, and the remaining whole monomer...

Embodiment 1-2~1-8 and comparative example 1-1~1-6

[0317] As shown in Table 1 and Table 2, a monomer emulsion was prepared in the same manner as in Example 1-1, changing the types and compounding amounts of the raw material monomers and emulsifiers. Moreover, using the said monomer emulsion, it carried out similarly to Example 1-1, and obtained the water dispersion type acrylic adhesive composition and the adhesive sheet. In addition, Table 1 and Table 2 show the solvent-insoluble content and the weight-average molecular weight (Mw) of the solvent-soluble content of the acrylic emulsion polymers obtained in Examples and Comparative Examples.

[0318] [evaluate]

[0319] The water-dispersed acrylic pressure-sensitive adhesive compositions and pressure-sensitive adhesive sheets obtained in Examples and Comparative Examples were evaluated by the following measurement methods or evaluation methods. In addition, the evaluation results are shown in Table 1 and Table 2.

[0320] (1) Elongation at break of crosslinked acrylic adhesi...

Embodiment 2-1

[0377] (Preparation of Acrylic Emulsion Polymer)

[0378] Mix 90 parts by weight of water in the container, and 94 parts by weight of 2-ethylhexyl acrylate (2EHA) as shown in Table 3, 2 parts by weight of methyl methacrylate (MMA), 4 parts by weight of acrylic acid (AA), react 6 parts by weight of a nonionic anionic emulsifier (manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd., trade name "Aquaron HS-10"), and then stirred and mixed with a high-speed mixer to prepare a monomer emulsion. Then, 50 parts by weight of water, 0.01 part by weight of a polymerization initiator (ammonium persulfate) and 10% by weight of the monomer emulsion prepared above are added to a reaction vessel having a condenser tube, a nitrogen introduction tube, a thermometer and an agitator. amount, emulsion polymerization was carried out at 75° C. for 1 hour while stirring. Thereafter, 0.07 parts by weight of a polymerization initiator (ammonium persulfate) was added, and the remaining whole monomer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| composition ratio | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com