Recombinant protein photosensitizer for targeting epidermal growth factor receptor (EGFR) and preparation method of recombinant protein photosensitizer

A recombinant protein and photosensitizer technology, applied in the field of recombinant protein photosensitizer preparation, can solve the problems of increased toxic and side reactions, high cost, low yield and the like, and achieves the effect of overcoming chemically coupled photosensitizers, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

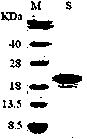

[0033](2) Fermentation and purification of recombinant protein photosensitizer: take 5ml of recombinant strains, inoculate with 100ml LB liquid medium, culture at 37°C for 8h, transfer to 28°C for culture, induce expression with IPTG for 12h, sonicate the cells, and use nickel affinity Chromatographic column purification of protein, SDS-PAGE gel electrophoresis detection of protein, such as figure 2 As shown, the protein size is about 22kD, and the 6×His tag is removed by TAGZyme to obtain a purified recombinant protein photosensitizer.

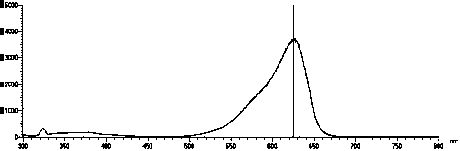

[0034] (3) Analysis of optical properties of recombinant proteins: Scan two optically active recombinant proteins at 400-800nm with a visible spectrophotometer to observe the characteristic absorption peaks of the proteins; use a fluorescence spectrophotometer to analyze the fluorescence spectra of the two recombinant proteins Properties were detected, and the excitation wavelength and excitation peak of the protein were observed. The rec...

Embodiment 2

[0038] (2) Fermentation and purification of recombinant protein photosensitizer: take 800ml of recombinant strains, inoculate in a 5L fermenter containing 4L LB liquid medium, incubate at 37°C for 4h, add 800ml of feeding medium for another 3h, transfer to 28°C Cultivate, induce expression with IPTG for 12 hours, sonicate the bacteria, purify the protein with a nickel affinity column, and detect the protein by SDS-PAGE gel electrophoresis, such as figure 2 As shown, the protein size is about 22kD, and the 6×His tag is removed by TAGZyme to obtain a purified recombinant protein photosensitizer.

[0039] (3) Analysis of optical properties of recombinant proteins: Scan two optically active recombinant proteins at 400-800nm with a visible spectrophotometer to observe the characteristic absorption peaks of the proteins; use a fluorescence spectrophotometer to analyze the fluorescence spectra of the two recombinant proteins Properties were detected, and the excitation wavelength ...

Embodiment 3

[0043] (2) Fermentation and purification of recombinant protein photosensitizer: take 800ml of recombinant strain, inoculate in a 5L fermenter containing 4L LB liquid medium, incubate at 37°C for 4h, inoculate into a culture tank containing 80L medium, incubate for 4h, Add 15L of feed medium, culture at 37°C for another 3h, transfer to 28°C for culture, induce expression with IPTG for 12h, sonicate the bacteria, purify the protein with a nickel affinity column, and detect the protein by SDS-PAGE gel electrophoresis, such as figure 2 As shown, the protein size is about 22kD, and the 6×His tag is removed by TAGZyme to obtain a purified recombinant protein photosensitizer.

[0044] (3) Analysis of optical properties of recombinant proteins: Scan two optically active recombinant proteins at 400-800nm with a visible spectrophotometer to observe the characteristic absorption peaks of the proteins; use a fluorescence spectrophotometer to analyze the fluorescence spectra of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com