Type I collagen modified porous titanium coat and making method thereof

A technology of porous titanium and collagen, applied in medical science, prosthesis, etc., can solve the problems of easy desorption, limited collagen, instability, etc., and achieve the effects of good biological performance, good repeatability, and good fixation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

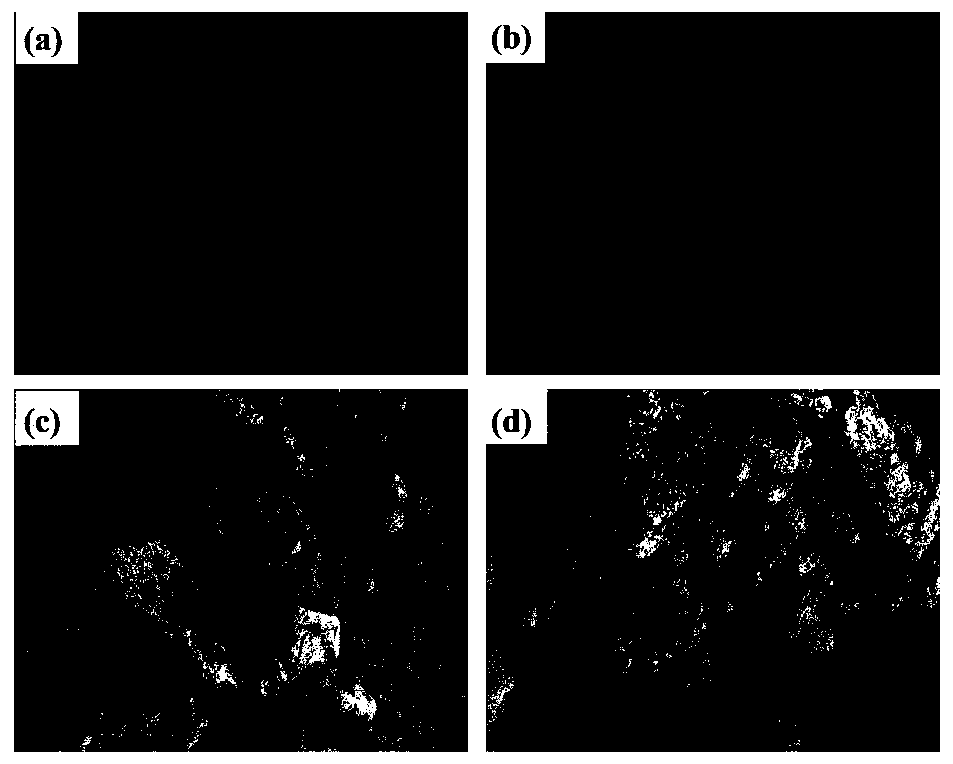

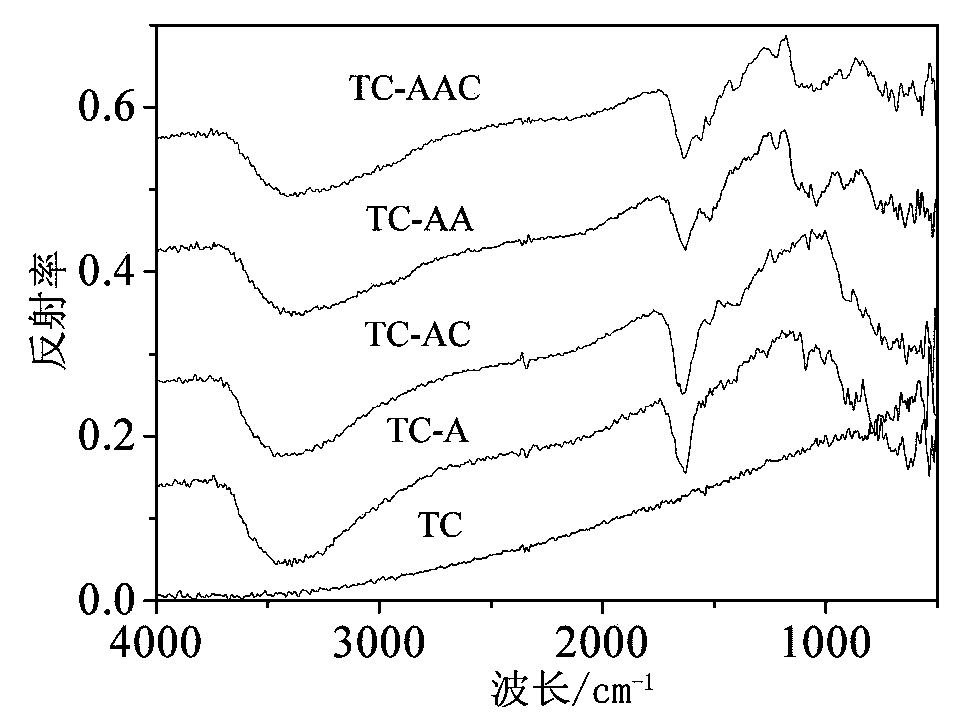

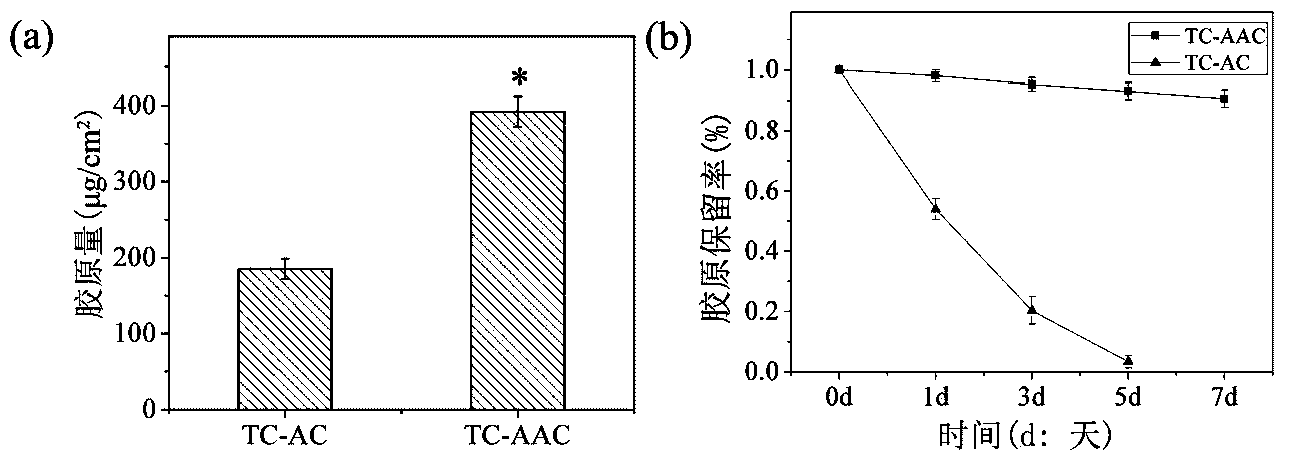

Image

Examples

preparation example Construction

[0024] (1) Preparation of titanium coating: The titanium coating was prepared by plasma spraying technology.

[0025] (2) Alkali treatment: immerse the titanium coating in a NaOH solution with a concentration of 5-10M and keep it warm at 60-80°C for 6-12 hours. After taking it out, it can be cleaned with deionized water ultrasonically, and the ultrasonic cleaning can last for about 5 minutes. Here, 5-10M NaOH is used as the lye for alkali treatment, but it should be understood that other suitable lyes are also applicable, such as potassium hydroxide.

[0026] (3) Aging in deionized water: Soak the porous titanium coating obtained by alkali treatment in deionized water at 40-80°C for 3-7 days. The water can be changed once a day, and finally dried at 40°C.

[0027] (4) Silanization: Soak the dry porous titanium coating in a 5-10% aminopropyltriethoxysilane (APS) / toluene solution, heat the solution to boiling, condense and reflux, and react for 6-12 hours , after cooling, ultr...

Embodiment 1

[0031] [Preparation of modified titanium coating based on covalent bond immobilization of type I collagen]

[0032] The titanium coating (marked as TC) was prepared by plasma spraying technology. The prepared titanium coating was immersed in 5M NaOH solution, kept at 80°C for 12h, cleaned with deionized water ultrasonically, and aged in deionized water at 60°C. Leave for 7 days, change the water once a day, and dry at 40°C. The alkali-treated modified titanium coating is marked as TC-A. Soak the dried sample TC-A in a 10% APS / toluene solution, heat the solution to boiling, condense and reflux, and react for 12 hours. After cooling, it was ultrasonically cleaned once with alcohol and twice with deionized water, and dried in vacuum. Silanized titanium coatings are designated TC-AA. Soak the sample TC-AA in a solution with a concentration of 1 mg / mL type I collagen / 5 mM acetic acid. 1 mL of 120 mg / mL EDC aqueous solution and 1 mL of 30 mg / mL NHS aqueous solution were dropped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com