Extraction device and extraction method for tobacco bois flavors in tobacco processing waste gas

A technology of tobacco leaf processing and extraction equipment, which is applied in the direction of essential oils/flavors, separation methods, chemical instruments and methods, etc., can solve the problems of low recovery rate of spices and poor quality of spices, and achieve improved extraction recovery rate, convenient operation, and high performance reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

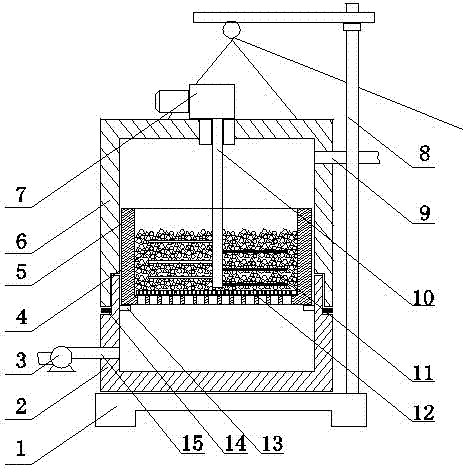

[0023] Such as figure 1 As shown, a device for extracting tobacco flavor and fragrance from tobacco leaf processing waste gas of the present invention includes a fragrance collector whose base 1 communicates with the waste gas exhaust pipe. The butt joint structure of the seam and the sealing gasket 14. The upper part of the lower section 2 of the housing is provided with a fragrance absorption screen 5 through the flange or the boss 13, and the absorbent 4 is spread in the fragrance absorption screen 5. Tube 9. The absorbent 4 is composed of 30 parts of activated carbon, 30 parts of silica gel and 30 parts of zeolite in parts by weight. The particle diameter of the absorbent 4 is 3 mm, and has a larger surface area for the adsorption of spices in the exhaust gas. The thickness of the absorbent is 10 cm, which can pass the exhaust gas relatively smoothly, and make the exhaust gas and the absorbent There is ample opportunity for contact absorption. One deck of screen cloth ...

Embodiment 2

[0027] This solution is basically the same as that of Example 1, except that the absorbent 4 is composed of 20 parts by weight of activated carbon, 40 parts of silica gel and 40 parts of zeolite. The particle diameter of the absorbent 4 is 1.5 mm, and has a larger surface area for the adsorption of spices in the exhaust gas. The paving thickness of the absorbent 4 is preferably 20 cm, and each layer of paddles 11 is radially arranged with 3 pieces; In the process of extracting tobacco flavors and fragrances, the rotation speed of the stirring paddle was adjusted to 20 rpm; the absorption time was set to 36 hours. According to laboratory analysis, the recovery rate of tobacco flavors and fragrances in the exhaust gas was 91.6%.

Embodiment 3

[0029] This solution is basically the same as that of Example 1, except that the absorbent 4 is composed of 10 parts by weight of activated carbon, 50 parts of silica gel and 50 parts of zeolite. The particle size of the absorbent 4 is 1 mm, and has a larger surface area for the adsorption of tobacco flavors and fragrances in the exhaust gas. The thickness of the absorbent 4 is 30 cm, and each layer of blades 11 is radially arranged with 4 pieces; In the process of extracting tobacco flavors and fragrances, the rotation speed of the stirring paddle was adjusted to 10 rpm; the absorption time was set to 48 hours, and the recovery rate of tobacco flavors and fragrances in the exhaust gas was 95.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com