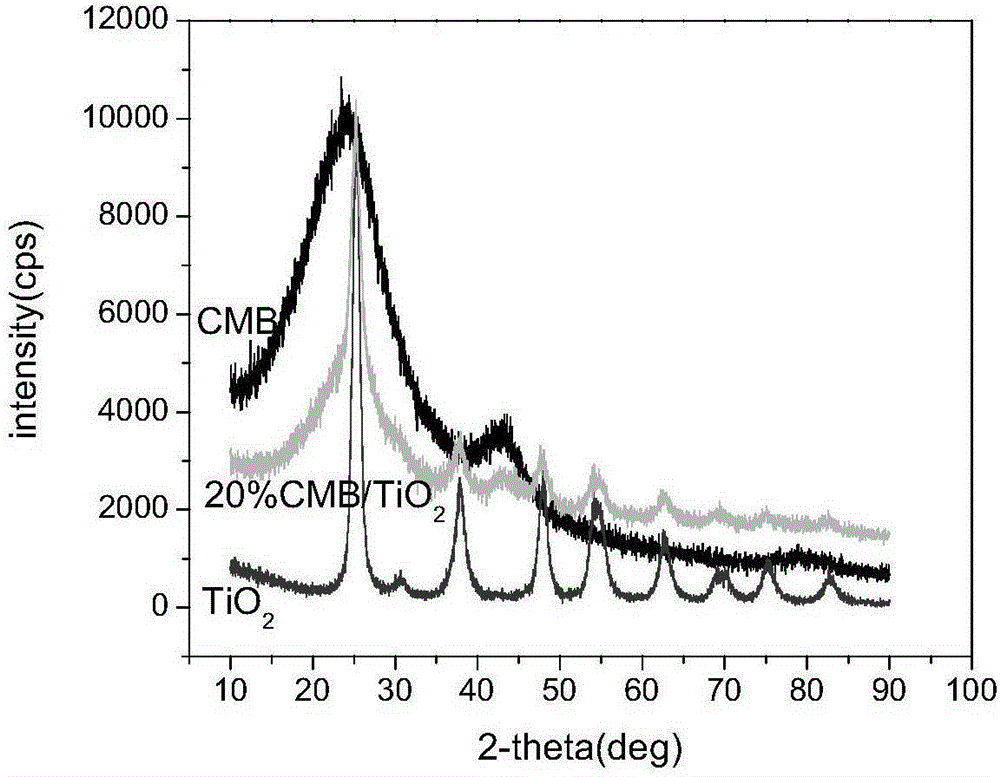

A kind of porous carbon microsphere tio2 composite material and its preparation method and application

A composite material and porous carbon technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of difficult photocatalyst recovery and low catalytic degradation efficiency, and achieve faster photolysis speed and product detachment speed, high catalytic degradation efficiency, and less agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

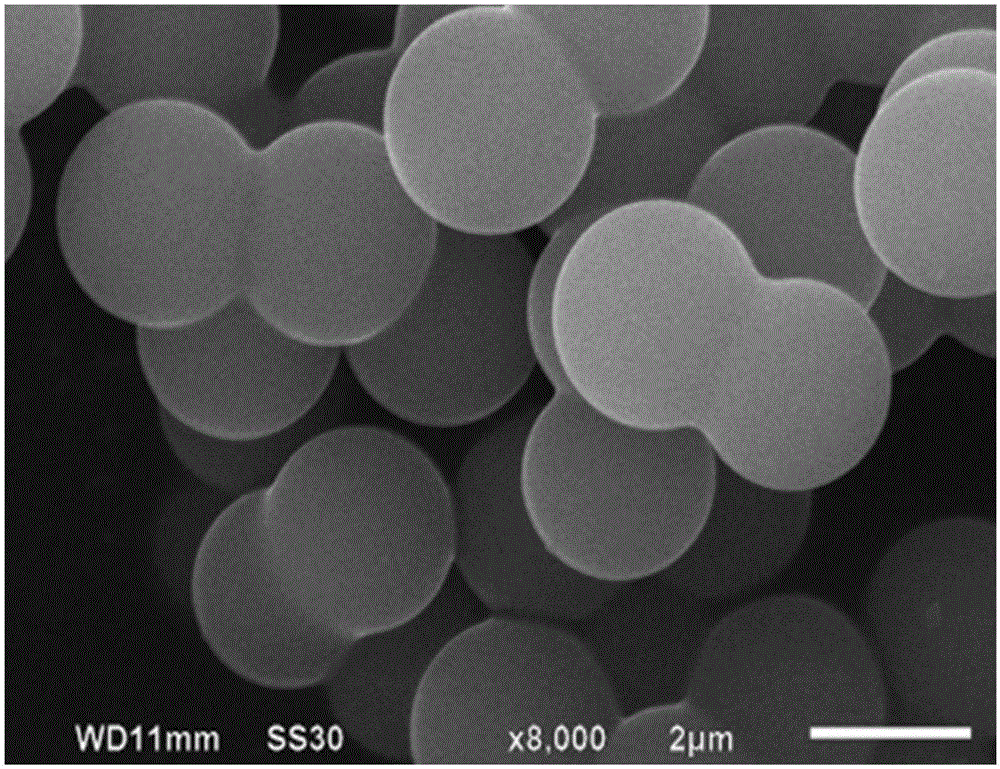

[0041] 1) Preparation of carbon microsphere precursor:

[0042] A certain amount of glucose is dissolved in distilled water to make a concentration of 1.5molL -1 The solution was magnetically stirred to fully dissolve the glucose in distilled water, and then transferred to a 100mL hydrothermal reactor to reach 75% of the volume of the reactor. After reacting at 180°C for 14 hours, take out the reaction kettle, wait for the reaction kettle to cool down to room temperature, take out the product, filter it with suction, wash alternately with distilled water and absolute ethanol until the pH value is about 7, dry at 80°C for 12 hours, and obtain carbon microspheres Precursor.

[0043] 2) Preparation of carbon microspheres:

[0044] The precursor of structured carbon microspheres was carbonized at 750°C in an Ar gas atmosphere for 1 h to obtain structured carbon microspheres.

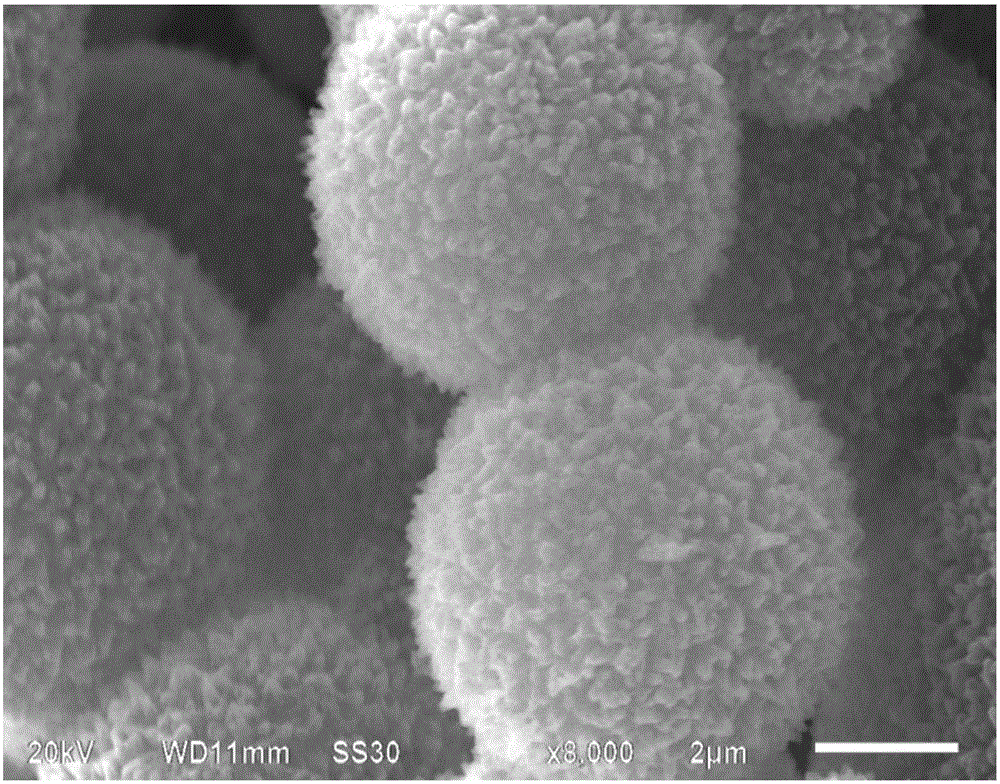

[0045] 3) Preparation of porous carbon microspheres:

[0046] Put the prepared carbon microspheres in...

Embodiment 2

[0050] 1) Preparation of carbon microsphere precursor:

[0051] A certain amount of glucose is dissolved in distilled water to make a concentration of 2molL -1 The solution was magnetically stirred to fully dissolve the glucose in distilled water, and then transferred to a 100mL hydrothermal reactor to reach 70% of the volume of the reactor. After reacting at 180°C for 16 hours, take out the reaction kettle, wait for the reaction kettle to cool to room temperature, take out the product, filter it with suction, wash alternately with distilled water and absolute ethanol until the pH value is about 7, dry at 80°C for 12 hours, and obtain carbon microspheres Precursor.

[0052] 2) Preparation of carbon microspheres:

[0053] The carbon microsphere precursor was carbonized at 700°C in an Ar gas atmosphere for 2h to obtain carbon microspheres.

[0054] 3) Preparation of porous carbon microspheres:

[0055] Put the prepared carbon microspheres into an Erlenmeyer flask, slowly add...

Embodiment 3

[0059] 1) Preparation of carbon microsphere precursor:

[0060] A certain amount of glucose is dissolved in distilled water to make a concentration of 1molL -1 The solution was magnetically stirred to fully dissolve the glucose in distilled water, and then transferred to a 100mL hydrothermal reactor to reach 60% of the volume of the reactor. After reacting at 160°C for 18 hours, take out the reaction kettle, wait for the reaction kettle to cool to room temperature, take out the product, filter it with suction, wash alternately with distilled water and absolute ethanol until the pH value is about 7, dry at 60°C for 14 hours, and obtain carbon microspheres Precursor.

[0061] 2) Preparation of carbon microspheres:

[0062] The structured carbon microsphere precursor was carbonized at 600°C in an Ar gas atmosphere for 3h to obtain the structured carbon microspheres.

[0063] 3) Preparation of porous carbon microspheres:

[0064] Put the prepared carbon microspheres into an Er...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com