Broad-spectrum crop biomass pretreatment system

A technology for crops and biomass, which is applied in the field of broad-spectrum crop biomass pretreatment system, can solve the problems of insufficiency in processing capacity or scale, large collection radius, and increased cost, and achieve strong material adaptability, large processing capacity, The effect of energy homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following is only exemplary and does not limit the protection scope of the present invention.

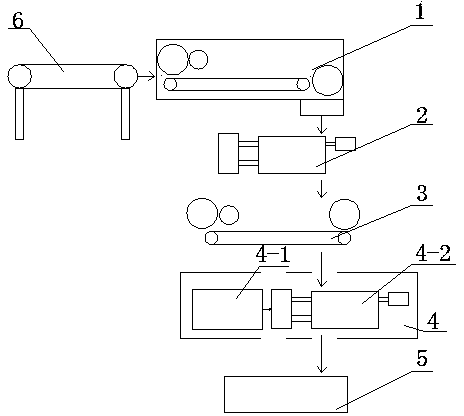

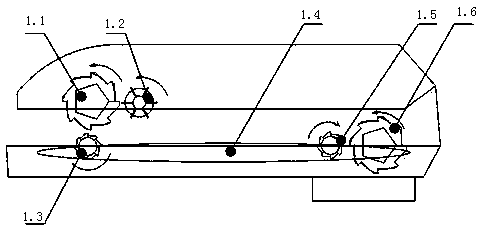

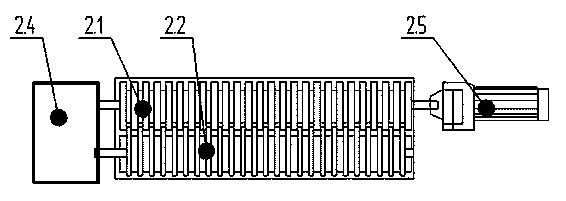

[0031] Reference attached figure 1 , a broad-spectrum crop biomass pretreatment system, including a primary feeding device 1, a primary pulverizer 2, a secondary feeding device 3, a secondary fine powder machine 4 and a homogenizer 5 arranged in sequence. Among them, the primary feeding device 1 is used to cut the materials to be processed into segments and blocks, and discharge the obtained segmental and block materials; the primary pulverizer 2 is used to crush the materials discharged from the primary feeding device 1. Segmental and blocky materials to obtain granular materials; the secondary feeding device 3 is used to break the granular materials and discharge the obtained materials; the secondary fine powder machine 4 is used to fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com