Recovery utilization method of continuous fiber-reinforced thermoplastic composite waste material

A technology of reinforced thermoplastic and continuous fiber, applied in the field of composite materials, can solve the problems of fiber damage and performance degradation, and achieve the effect of simple equipment, low price and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

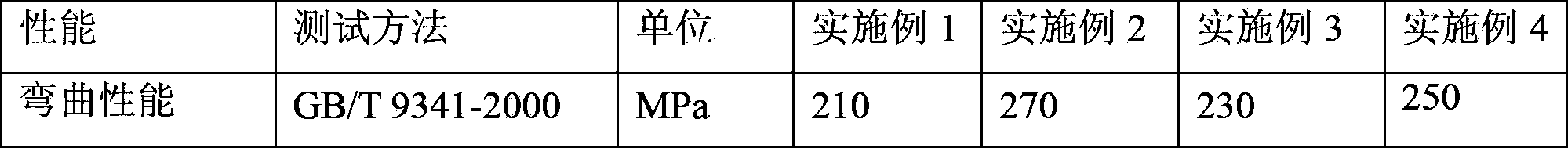

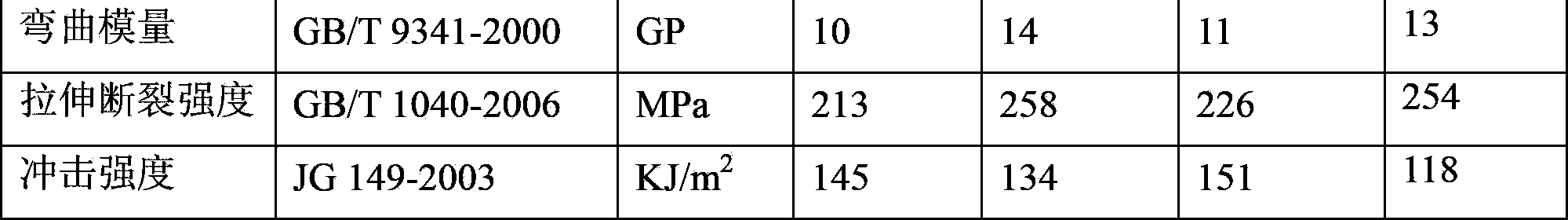

Examples

Embodiment 1

[0040] Example 1 Recycling of continuous fiber reinforced polypropylene waste

[0041] (1) Cut the continuous fiber reinforced polypropylene material waste to a size of 150×150mm; then put it into an aqueous solution with a concentration of 5wt% caustic soda detergent at 80°C for washing; dry it at 120°C for 10 minutes; then crush it to obtain Crushed material with a fiber length of 30-50mm;

[0042] (2) The continuous glass fiber reinforced polypropylene prepreg with 50 parts by weight of fiber and 50 parts by weight of resin is flattened by traction and rolling;

[0043] (3) Flatten the pulverized material with an area density of 1200g / ㎡ obtained in step (1), and evenly spread it on the continuous glass fiber reinforced polypropylene prepreg after rolling in step (2), and then place it on the pulverized material Lay a layer of continuous glass fiber reinforced polypropylene prepreg on the surface;

[0044] (4) Pull the material obtained in step (3) at 0.8m / min by a tractio...

Embodiment 2

[0044] (4) Pull the material obtained in step (3) at 0.8m / min by a traction device; turn on the infrared oven for heating, and the heating temperature is 160°C; then use metal rollers to make it smooth and cool to 50°C with cooling water Coiled or cut. Example 2 Recycling Continuous Fiber Reinforced Polypropylene Scrap

[0045] (1) Cut the continuous fiber reinforced polypropylene material waste to a size of 180×180mm; then put it into an aqueous solution with a concentration of 5wt% caustic soda detergent at 80°C for washing; dry it at 120°C for 15 minutes; then crush it to obtain Crushed material with a fiber length of 30-50mm;

[0046] (2) The carbon fiber reinforced polypropylene fiber fabric with 50 parts by weight of fiber and 50 parts by weight of resin is flattened by traction and rolling;

[0047] (3) Set the areal density obtained in step (1) to 1200g / m 2 The crushed material is flattened, evenly spread on the carbon fiber reinforced polypropylene fiber fabric rol...

Embodiment 3

[0048] (4) Pull the material obtained in step (3) at 0.8m / min by a traction device; turn on the infrared oven to heat, and the heating temperature is 170°C; then roll it with a metal roller to make it smooth, and cool it to 50°C with cooling water. Coiled or cut. Example 3 Recycling of continuous fiber reinforced polypropylene waste

[0049] (1) Cut the continuous fiber reinforced polypropylene material waste to a size of 150×150mm; then put it into an aqueous solution with a concentration of 5wt% caustic soda detergent at 80°C for washing; dry it at 120°C for 20 minutes; then crush it to obtain Crushed material with a fiber length of 30-50mm;

[0050] (2) The continuous glass fiber reinforced polypropylene prepreg with 50 parts by weight of fiber and 50 parts by weight of resin is flattened by traction and rolling;

[0051] (3) Set the areal density obtained in step (1) to 1600g / m 2 The pulverized material is flattened, evenly placed on the continuous glass fiber reinforce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com