Halogen-free rubber-plastic foam heat insulating material

A technology of rubber and plastic foaming and thermal insulation materials, which is applied in the field of rubber and plastic foaming thermal insulation materials to achieve the effect of reducing casualties and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

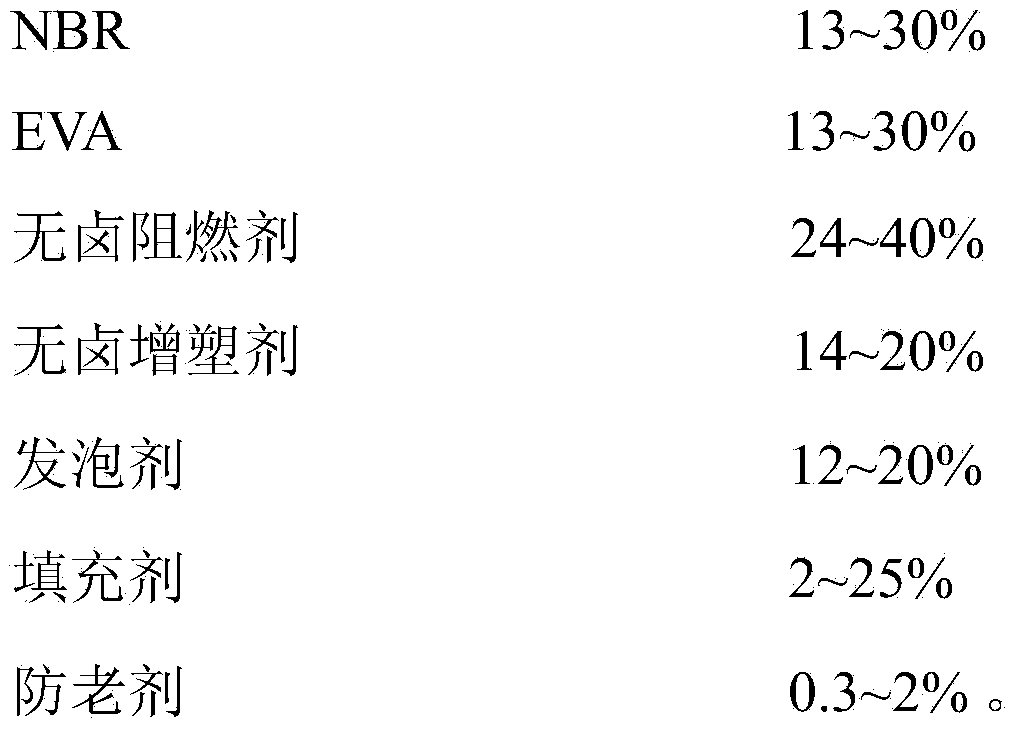

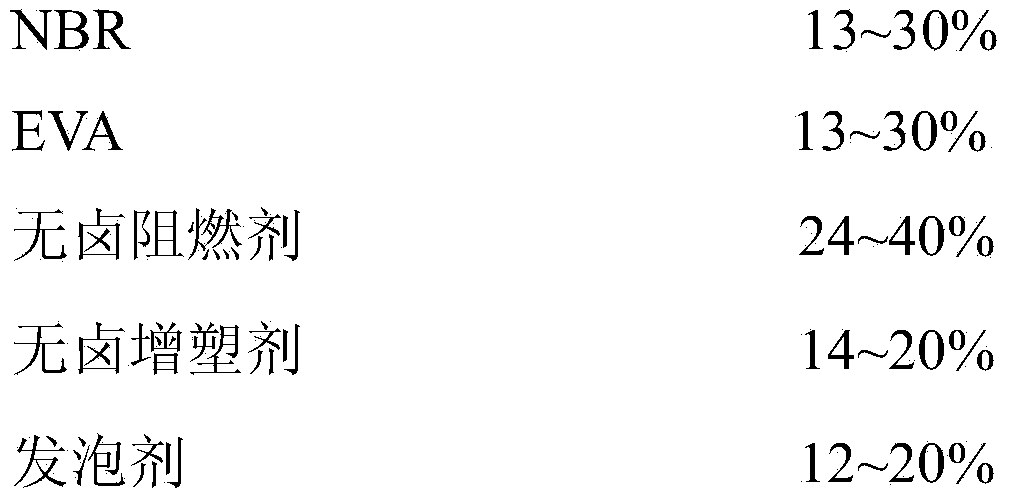

[0022] A halogen-free rubber and plastic foam insulation material, comprising the following components:

[0023] Main material: NBR15kg, EVA13kg;

[0024] Halogen-free flame retardant: aluminum hydroxide 24kg;

[0025] Halogen-free plasticizer: tricresyl phosphate 14kg;

[0026] Foaming agent: azodicarbonamide 12kg;

[0027] Filler: talcum powder 11kg, clay 7kg, calcium carbonate 3.7kg;

[0028] Anti-aging agent: anti-aging agent MB0.3kg.

[0029] The preparation method of the halogen-free rubber and plastic foam insulation material in this example: take the above-mentioned component raw materials, put them into a 75L internal mixer for mixing, and generate the mixed rubber; the mixed rubber is cut into pieces and added to the extruder to be pressed out to form; the formed product Send it into a hot air oven for vulcanization and foaming; then cool and cut to make the final product.

Embodiment 2

[0031] A halogen-free rubber and plastic foam insulation material, comprising the following components:

[0032] Main material: NBR13kg, EVA13kg;

[0033] Halogen-free flame retardant: aluminum hydroxide 25kg, magnesium hydroxide 14kg;

[0034] Halogen-free plasticizer: tricresyl phosphate 20kg;

[0035] Foaming agent: azodicarbonamide 12kg;

[0036] Filler: talcum powder 2.1kg;

[0037] Anti-aging agent: anti-aging agent MB0.6kg, anti-aging agent DNP0.3kg.

[0038] In this example, the raw materials are weighed according to the above components, and the halogen-free rubber and plastic foam insulation material of this example is prepared according to the preparation method of Example 1.

Embodiment 3

[0040] Main material: NBR20kg, EVA18kg;

[0041] Halogen-free flame retardant: aluminum hydroxide 16kg, magnesium hydroxide 14kg;

[0042] Halogen-free plasticizer: tricresyl phosphate 17kg;

[0043] Foaming agent: azodicarbonamide 12kg;

[0044] Filler: talcum powder 2.1kg;

[0045] Anti-aging agent: anti-aging agent MB0.6kg, anti-aging agent DNP0.3kg.

[0046] In this example, the raw materials are weighed according to the above components, and the halogen-free rubber and plastic foam insulation material of this example is prepared according to the preparation method of Example 1.

[0047] According to the national fire protection standard "GB8624", the safety grades of the halogen-free rubber and plastic foam insulation materials prepared in the above three examples were tested, and the results are as follows:

[0048] Test items Example 1 Example 2 Example 3 Density (kg / m 3 ) 48 47 47 Oxygen Index 33 34 32 Smoke Density (Grade) 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com