A connection member between prefabricated concrete laminated floor slab and h-shaped steel beam

A technology of prefabricated concrete and laminated floor slabs, which is applied in the direction of building construction and construction, can solve the problems of poor effect and achieve the effects of reduced number, accurate construction positioning and steel saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment, further illustrate the present invention.

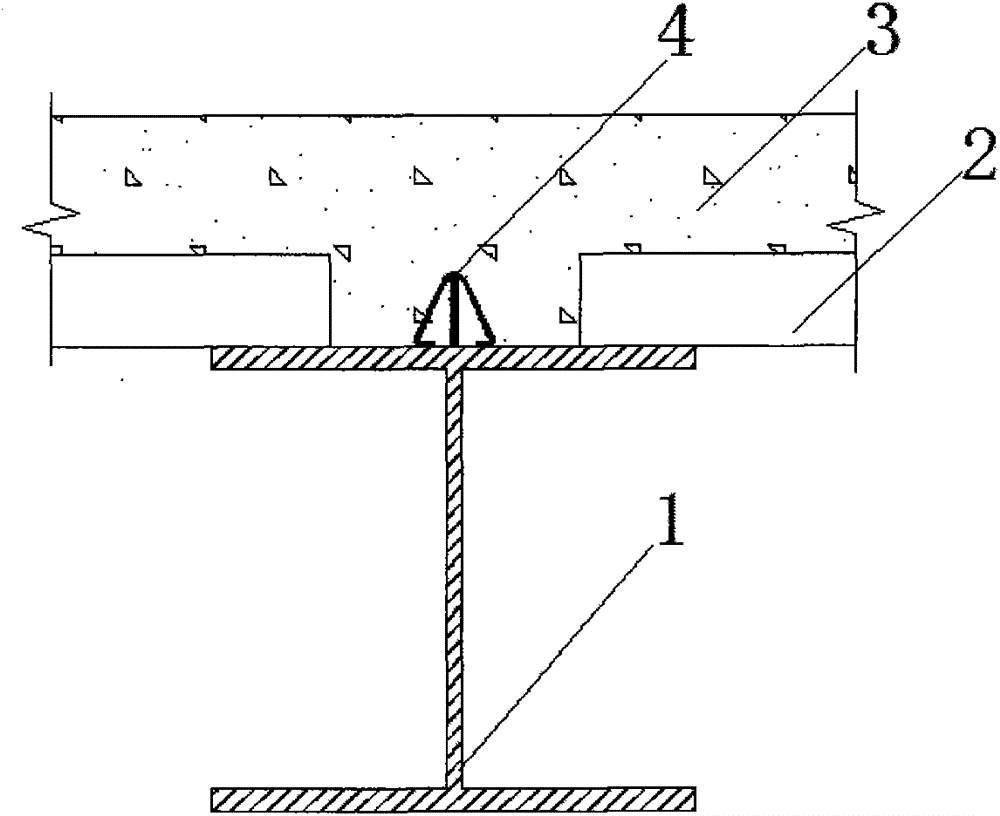

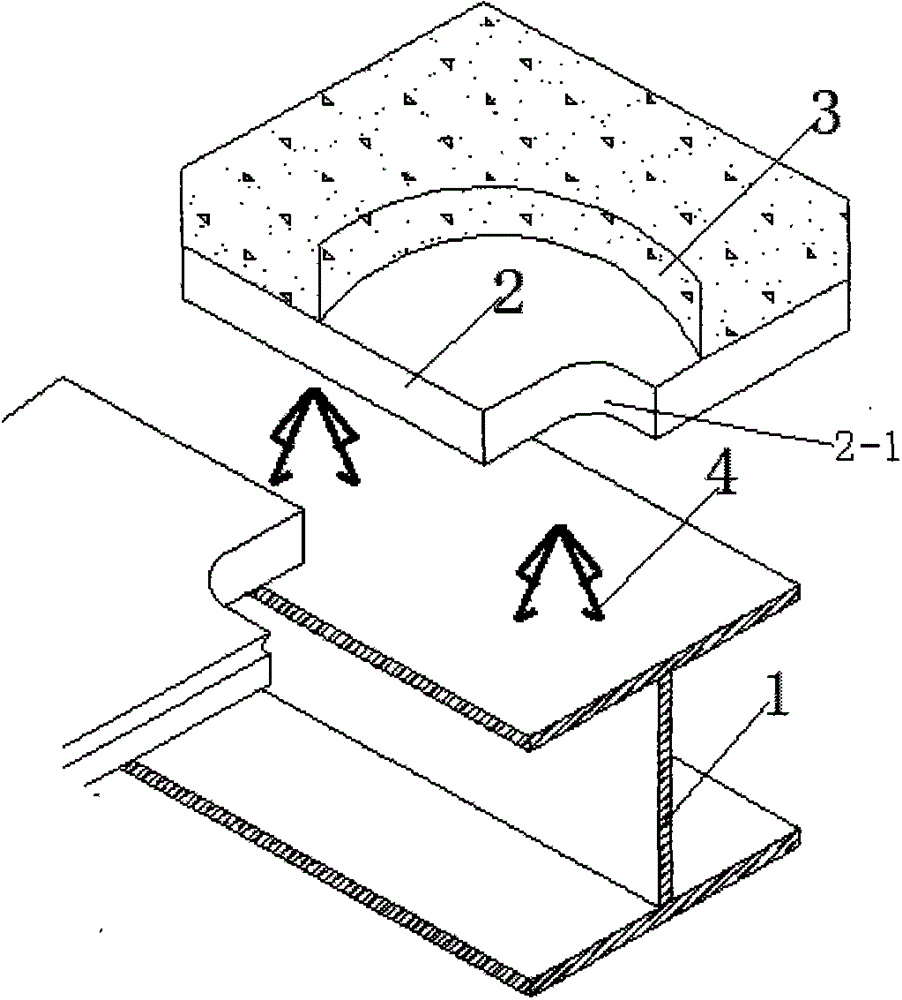

[0025] As shown in the figure, a connection member between a prefabricated concrete laminated floor slab and an H-shaped steel beam is characterized in that it includes an H-shaped steel beam (1), a prefabricated thin plate (2), a concrete layer (3), and four-corner bending bars ( 4),

[0026] The prefabricated thin plate (2) is located at the upper flange of the H-shaped steel beam (1), the prefabricated thin plate (2) has a reserved hole (2-1), and the upper flange of the H-shaped steel beam (1) There are four-corner bent bars (4) welded at the place, and the four-cornered bent bars (4) are located in the reserved holes (2-1) and pass through the concrete layer (3).

[0027] The concrete layer (3) is located on the upper part of the prefabricated thin plate (2) and in the reserved hole (2-1).

[0028] There are multiple quadrangular ribs (4). The thickness of the prefabricate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com