Bonding forming method of flexible stab-proof material and stab-proof body

A molding method and flexible technology, applied in the field of bonding and molding of stab-proof bodies and flexible stab-proof materials, can solve the problems of poor flexibility, easy deformation, thick thickness, etc., and achieve good softness and air permeability, excellent mechanical strength, The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

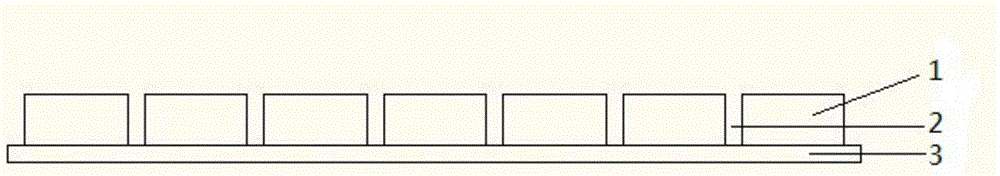

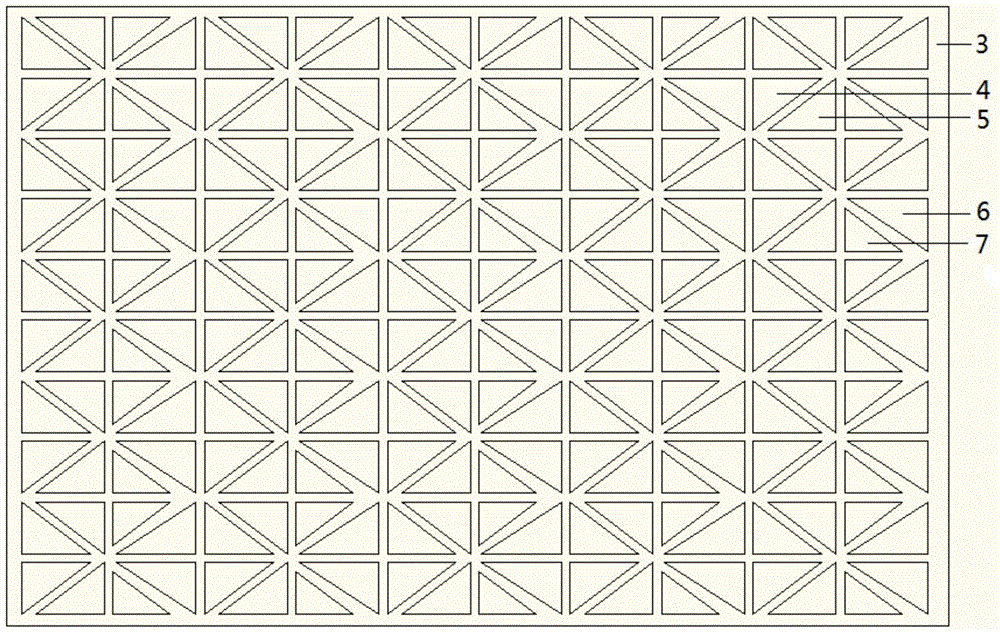

[0043] Refer to attached Figure 1-6 , the pattern of flexible stab-resistant composite material adopts image 3 , the base fabric is made of polyester woven plain fabric with a surface density of 270g / m 2, the warp and weft density is 178×194 (root / 10cm), the particles are polyformaldehyde resin particles, the particle diameter is 6mm, the particle height is 1.5mm, and the particle gap is 0.6mm. 7 layers of this anti-stab material are stacked alternately, and then the edges of each layer are sparsely stitched to each other, and then cut to make a protective body (stab-resistant liner). The total weight of the anti-stab clothing of specification 175cm, 90A prepared with this protective body is 2.8kg, and the thickness is 12.4mm. The stab-resistant clothing adopts the latest standard GA68-2008 of the public safety industry of the People's Republic of China to conduct a puncture test according to 24J energy, and the results show that the stab-resistant clothing fully meets the...

Embodiment 2

[0047] Refer to attached Figure 1-6 , the pattern of flexible stab-resistant composite material adopts Figure 5 , the base fabric is made of nylon woven plain fabric with a surface density of 260g / m 2 , The warp and weft density is 196×214 (root / 10cm), the particles are polyamide resin particles, the side length of the pentagon particles is 6mm, the side length of the square particles is 8mm, the particle height is 1.5mm, and the particle gap is 0.8mm. 6 layers of this stab-resistant material are stacked interlacedly, and the edges of each layer are sparsely stitched to each other, and then cut to make a protective body (stab-resistant liner). The total weight of the anti-stab clothing of specification 175cm, 90A prepared with this protective body is 2.5kg, and the thickness is 11.3mm. The stab-resistant clothing adopts the latest standard GA68-2008 of the public safety industry of the People's Republic of China to conduct a puncture test according to 24J energy, and the r...

Embodiment 3

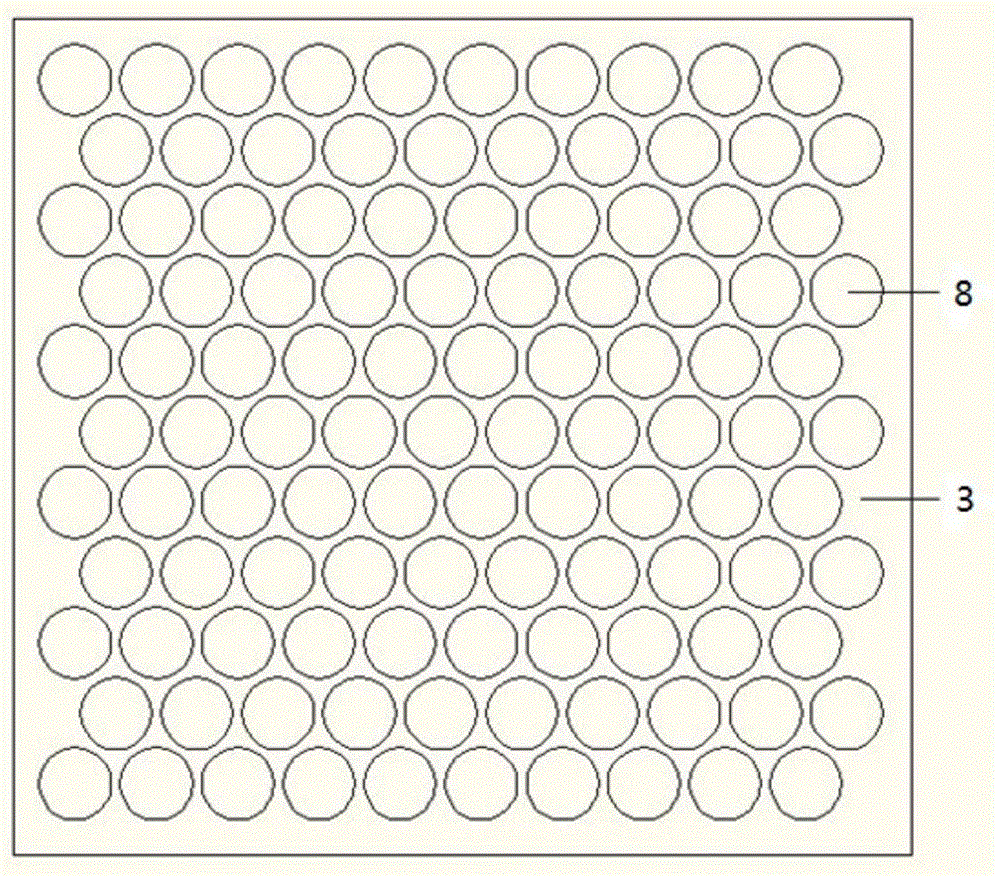

[0051] Refer to attached Figure 1-6 , the pattern of flexible stab-resistant composite material adopts Figure 6 , the base fabric is made of polyester woven plain fabric with a surface density of 270g / m 2 , The warp and weft density is 178×194 (root / 10cm), the particles are polycarbonate resin particles, the side length of the hexagonal particles is 6mm, the particle height is 1.5mm, and the particle gap is 0.8mm. Five layers of this anti-stab material are stacked interlacedly, and the edges of each layer are sparsely stitched to each other, and then cut to make a protective body (stab-proof liner). The total weight of the anti-stab clothing of specification 175cm, 90A prepared with this protective body is 2.3kg, and the thickness is 9.8mm. The stab-resistant clothing adopts the latest standard GA68-2008 of the public safety industry of the People's Republic of China to conduct a puncture test according to 24J energy, and the results show that the stab-resistant clothing f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com