Comprehensive performance test rig of vehicle electric power steering system

An electric power steering and system integration technology, applied in the direction of vehicle steering/jump performance, etc., to achieve real-time vehicle dynamics simulation environment and good real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

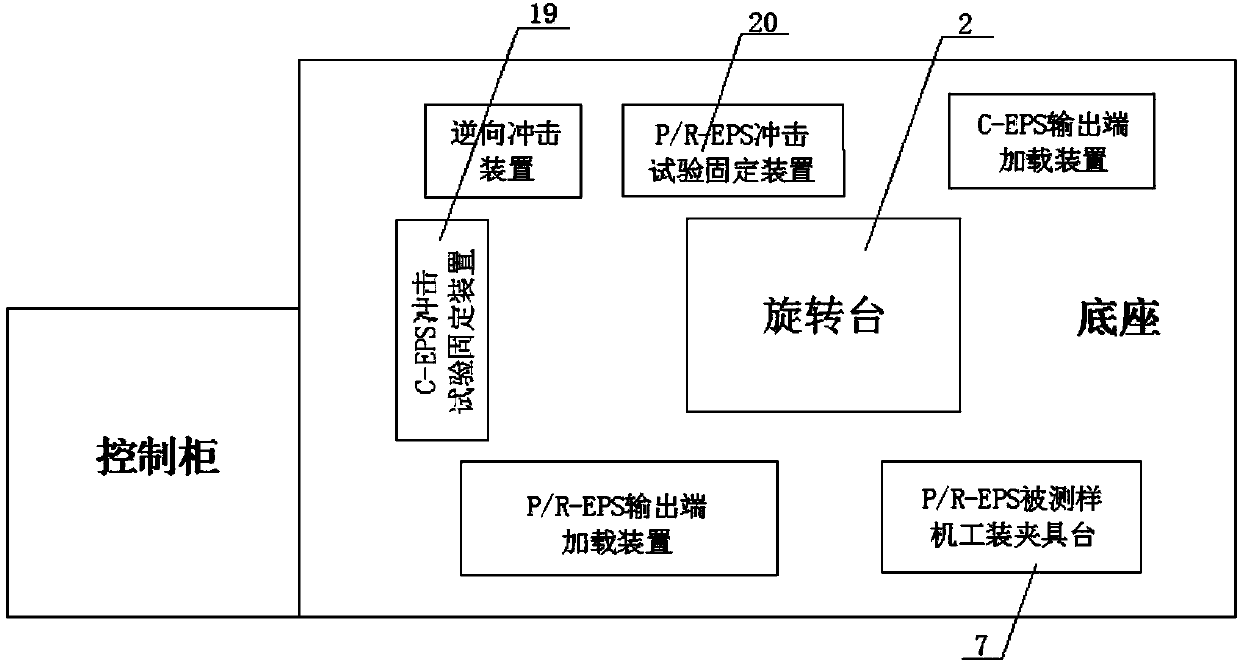

Embodiment 1

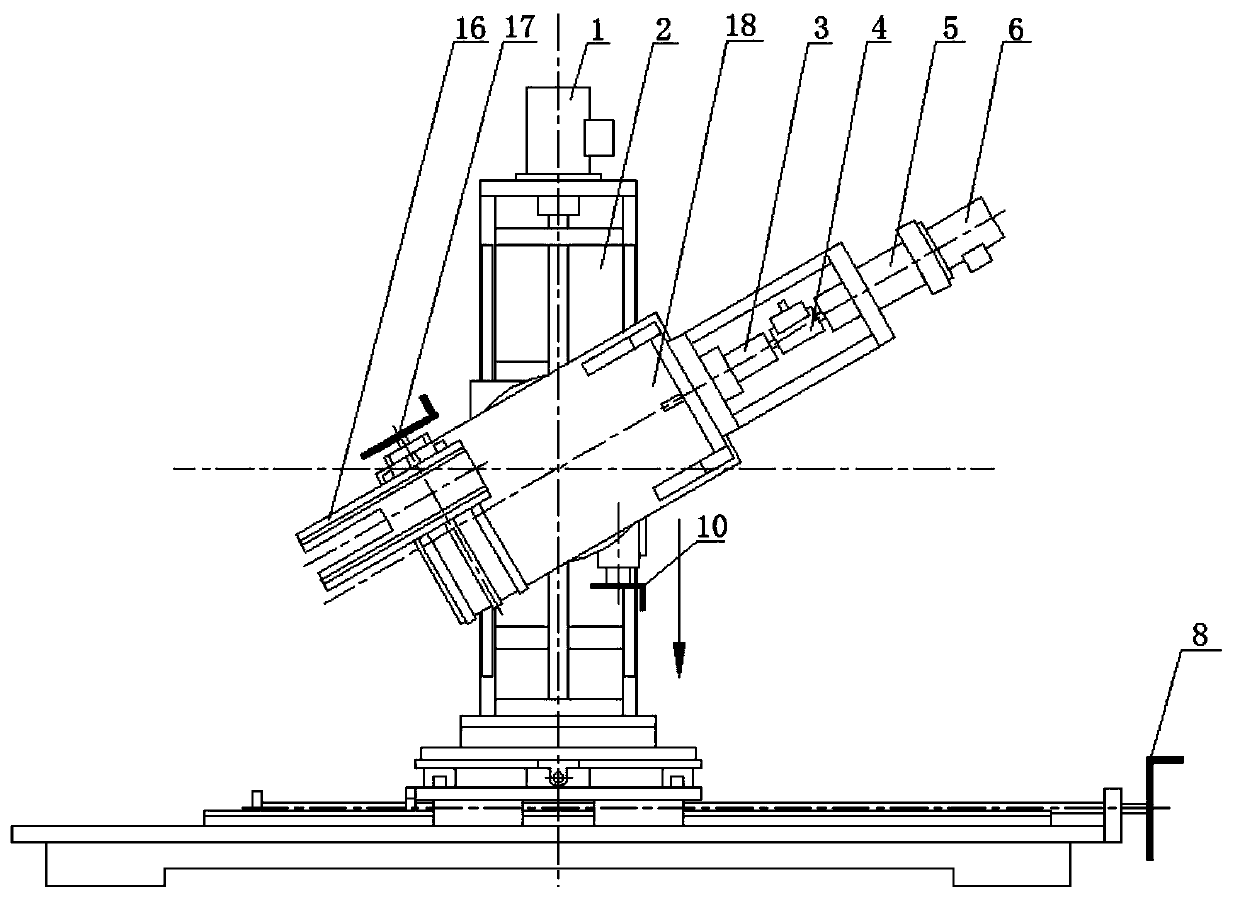

[0043] Embodiment 1: Functional test of C-EPS

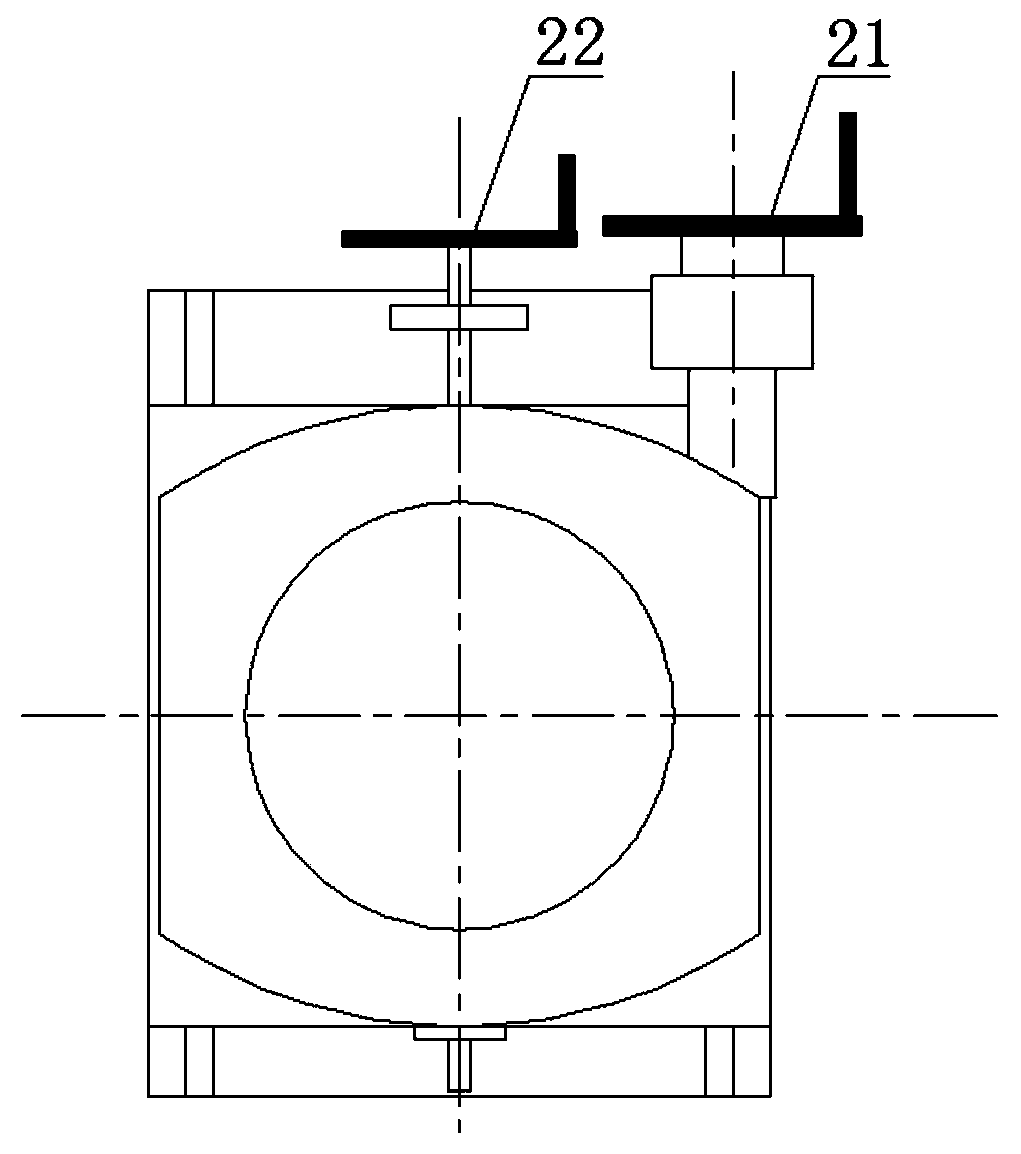

[0044] First, adjust the seventh handwheel 8, the fifth handwheel 21, and the sixth handwheel 22 respectively to place the turntable 2 at the test position, then fix the C-EPS tested prototype on the C-EPS tooling fixture 16, and the input drive It is connected with the C-EPS tested prototype by a sliding spline, and the C-EPS output loading device is connected with the C-EPS tested prototype by a double universal joint sliding connection. Adjust the third handwheel 23 to make the C-EPS loading assembly adjustment mechanism 24 rotate around the vertical direction, adjust the first handwheel 9 to change the pitch angle of the adjustment mechanism, adjust the handwheel 10 to change the pitch angle of the fixture plate 18, adjust the second The hand wheel 17 changes the vertical height of the C-EPS fixture 16 to ensure that the C-EPS tested prototype, the input drive, and the output rotary loader are in a straight line.

[0045] Af...

Embodiment 2

[0046] Embodiment 2: Functional test of P-EPS

[0047] The function test of P-EPS or R-EPS uses the loading device at the output end of P / R-EPS, which is a linear loader. Firstly, the P-EPS or R-EPS prototype 32 to be tested is installed on the jig table 7 , and the fifth hand wheel 21 is adjusted to place the rotary table 2 in the direction of the jig table 7 . The input driver is connected with the P-EPS or R-EPS tested prototype 32 by sliding splines. The loading device at the output end of the P / R-EPS loads the P-EPS or R-EPS sample machine 32 to be tested through the tie rod 33 .

[0048] After the installation is completed, operate the industrial computer, open the P / R-EPS performance test software, and select the function test. At this time, the first loading servo motor 15 of the loading device at the output end of the P / R-EPS will follow the vehicle speed given by the motion control card. The changing load signal is loaded, and the driving servo motor 6 of the input d...

Embodiment 3

[0049] Embodiment 3: Driver's power steering feel test

[0050] Adjust the third hand wheel 23 to rotate the C-EPS loading assembly adjustment mechanism 24 so that the loading device at the output end of the C-EPS faces the manual input device 34, and connect the manual input device 34 to the loading device at the output end of the C-EPS through the sliding spline connect.

[0051] After the installation is completed, operate the industrial computer, open the C-EPS performance test software, and select the driver's steering power-assisted feel test. At this time, the driver can feel the power-assisted feel of the steering gear to be tested by operating the steering wheel. At the same time, the first display shows the curves of the torque sensor voltage and the driving motor current changing with time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com