Numerical control elbow machining simulation method and device

A simulation method and pipe bending technology, applied in program control, computer control, general control system, etc., can solve problems such as poor versatility and cumbersome modeling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

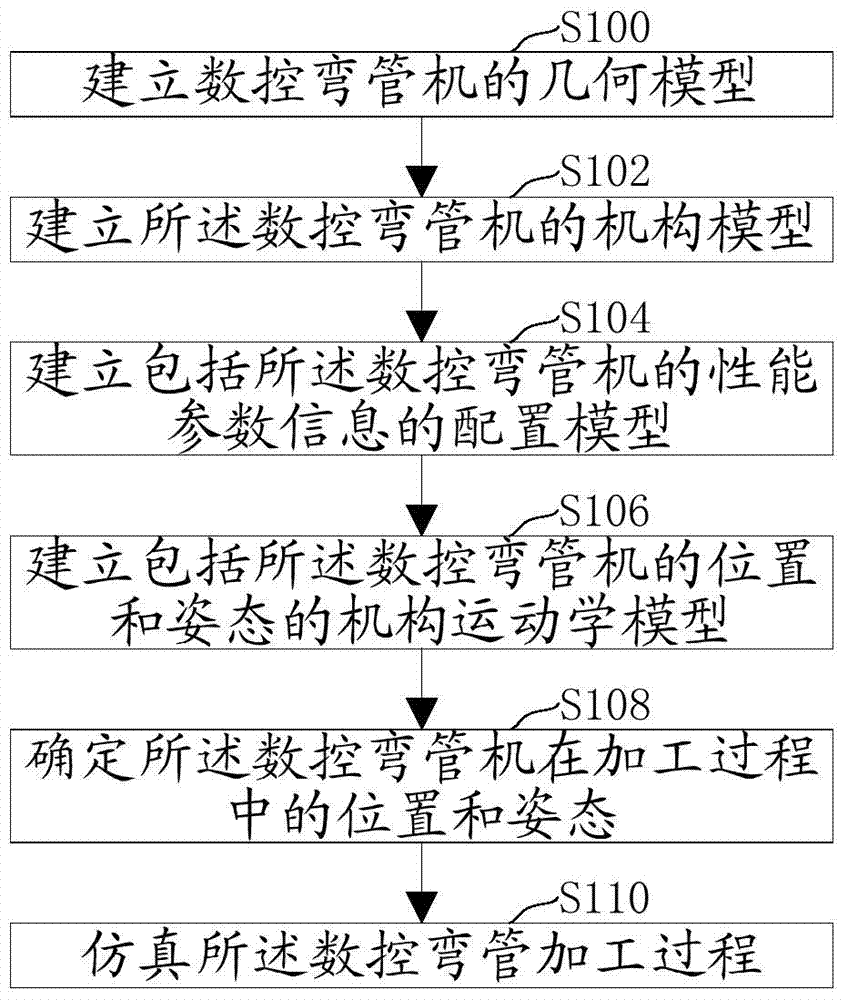

[0039] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

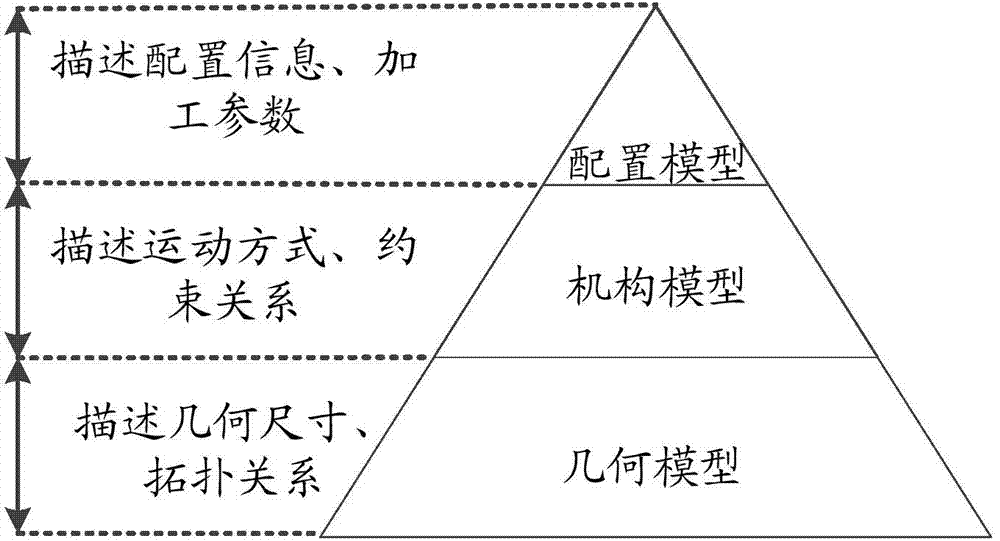

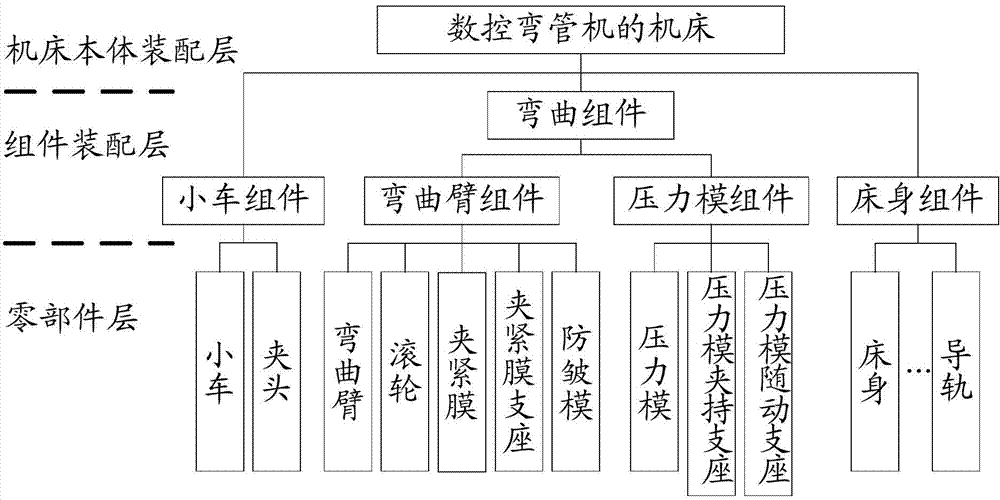

[0040] The embodiment provided by the present invention aims at the problem of complex modeling process and poor versatility of the digital pipe bending machine processing simulation method in the prior art, and provides a numerical control pipe bending processing simulation method and device, using the numerical control pipe bending machine as a multi- The space mechanism composed of components and kinematic pairs is established, and its mechanism information model is established. According to the motion law of the CNC pipe bending machine, its mechanism kinematics model is established, and the kinematic equation is solved by iterative method to obtain the generalized coordinates of the mechanism. The numerical control pipe bending process simulation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com