High-frequency large-power silicon carbide MOSFET module

A silicon carbide, high-power technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the power module power density is not high, the internal power loop parasitic inductance is large, and cannot meet the requirements of high power density and low parasitic inductance And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

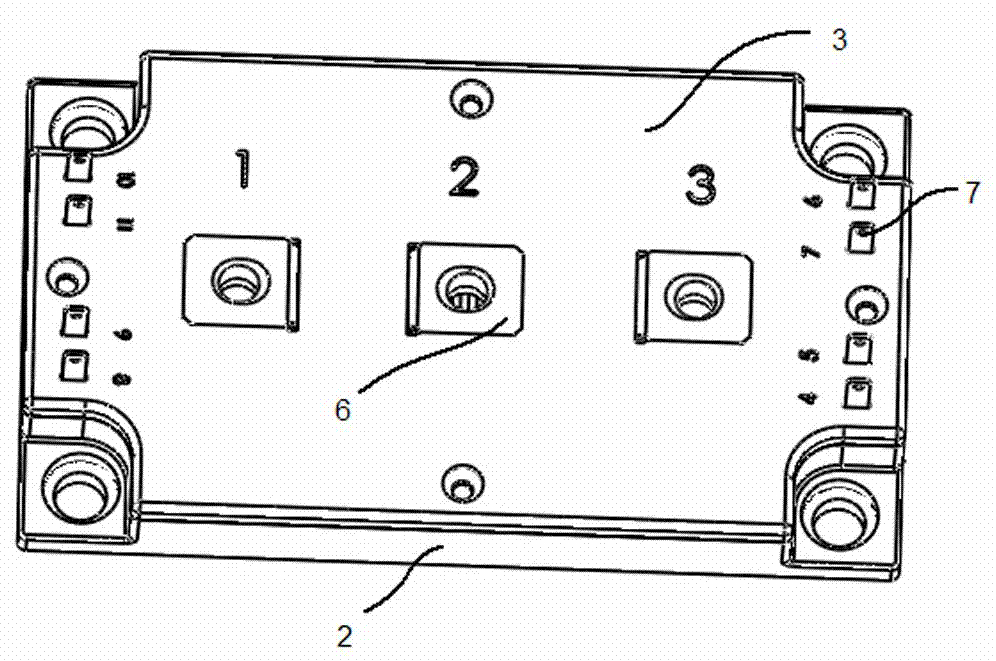

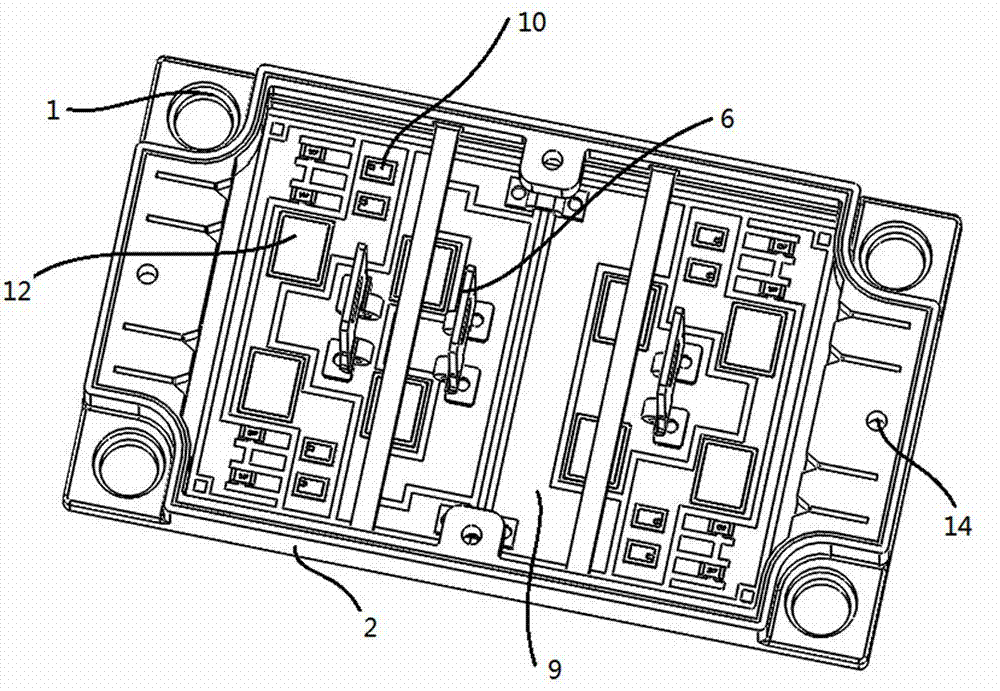

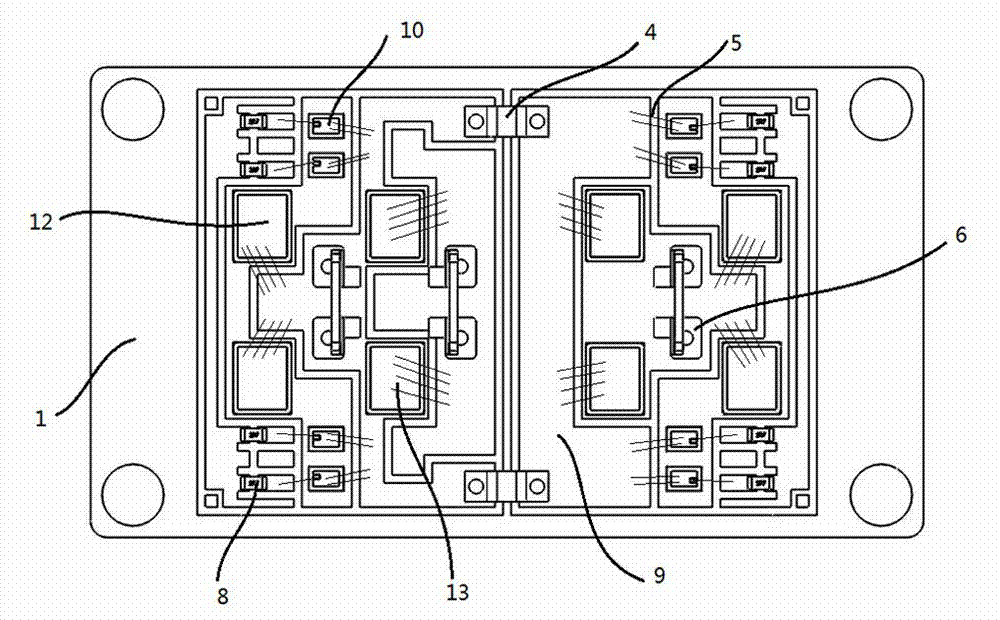

[0027] Embodiment: As shown in the figure, the present invention mainly includes: a heat dissipation substrate 1, a casing, and a circuit structure packaged in the casing; the casing includes a casing 2 and an outer cover 3 covering the casing, and the circuit structure includes power terminals 6. Signal terminal 7, insulating ceramic substrate 9, silicon carbide mosfet chip 10, silicon carbide SBD chip 12, 13;

[0028] The insulating ceramic substrate 9 is welded to the heat dissipation substrate 1 by high temperature reflow, and the silicon carbide mosfet chip 10 and the silicon carbide SBD chip 12, 13 are welded on the insulating ceramic substrate 9, and the silicon carbide mosfet chip 10 and the silicon carbide SBD chip 12, 13 are connected with the The circuit structure etched on the insulating ceramic substrate 9 is connected, and the silicon carbide mosfet chip 10 and the silicon carbide SBD chip 12, 13 are connected to each other through the aluminum wire 5, and at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com