Method for removing H2S in offshore oil production associated gas by utilizing seawater modified LO-CATII method

An associated gas removal technology, applied in separation methods, chemical instruments and methods, gas fuels, etc., can solve problems such as marine pollution, toxic desulfurization liquid, flammable floor space, etc., and achieve the effect of overcoming potential marine pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Measure fresh seawater in a 2L beaker and place it in a glass constant temperature water bath; (2) Weigh the complexing agent separately

[0021] m EDTA-2Na =0.945g, m HBDTA : 0.520, m 山梨糖醇 =0.07g, respectively added to beakers filled with seawater, and stirred continuously with a glass rod to dissolve completely; (3) Weigh Add in the above solution, after it is completely dissolved, measure its pH value to be acidic; (4) Slowly add anhydrous Na to the solution 2 CO 3 And keep stirring, when its pH=8, it will be made into seawater absorption liquid. Due to Fe 3+ It is unstable under alkaline conditions, therefore, the seawater absorption solution needs to be prepared immediately after use.

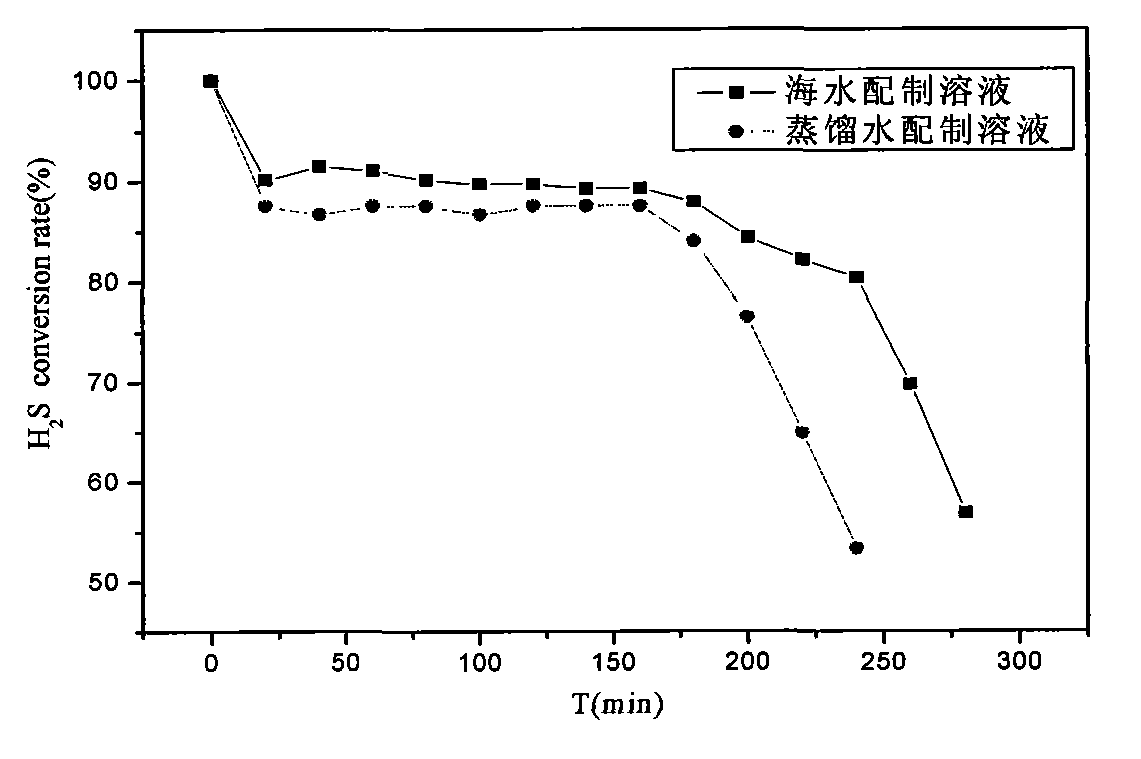

[0022] In addition, distilled water is used instead of seawater, and the distilled water absorption solution is prepared according to steps (1)-(4). The experimental conditions for desulfurization activity evaluation of the absorption liquid prepared by seawater and dist...

Embodiment 2

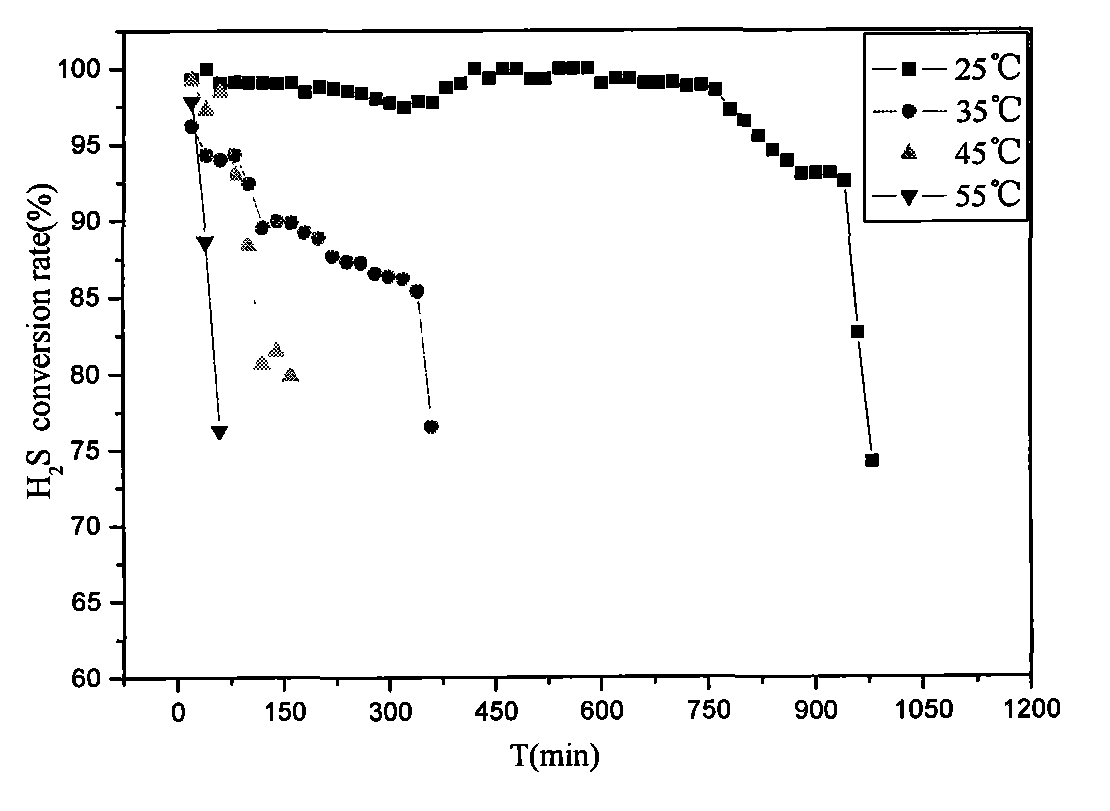

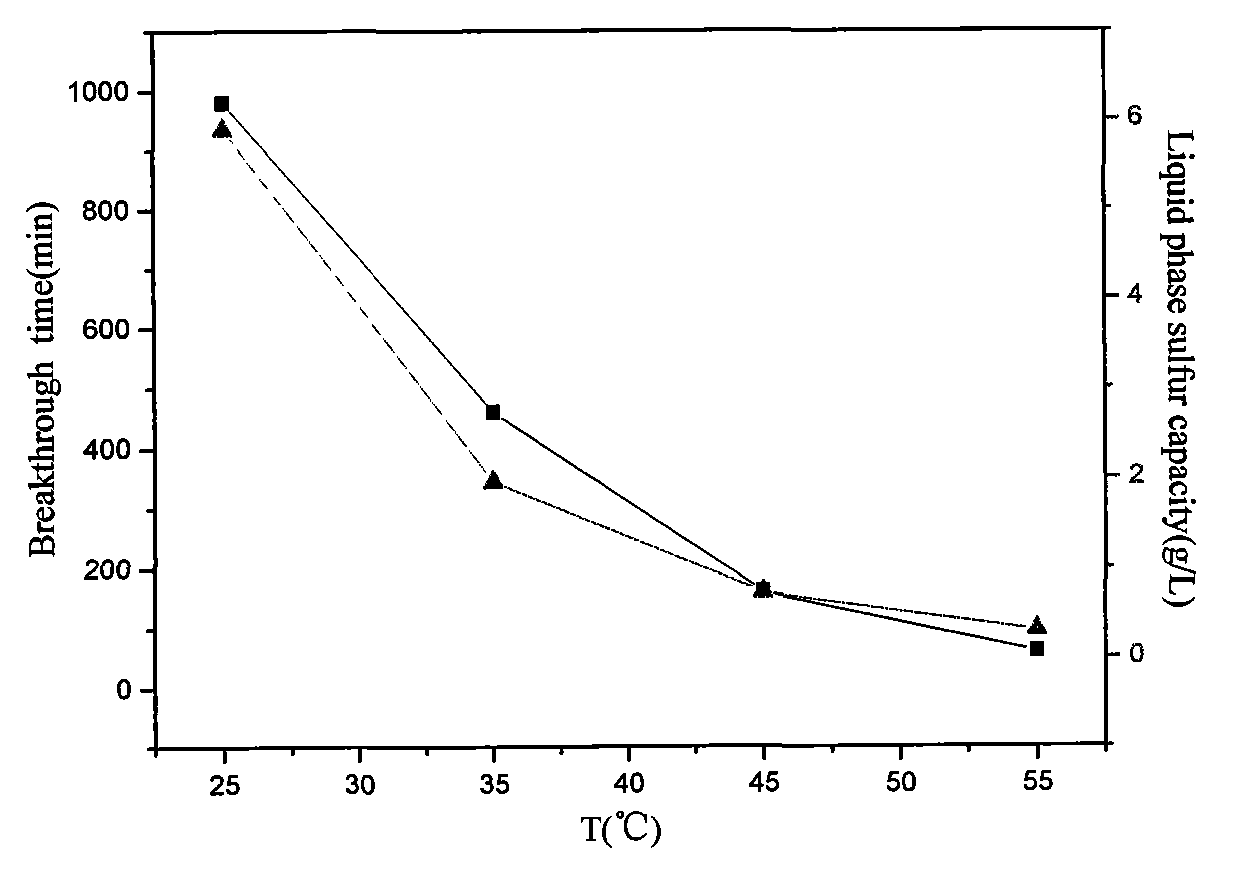

[0024] (1) Measure fresh seawater in a 2L beaker and place it in a glass constant temperature water bath; (2) Weigh the complexing agent m EDTA-2Na : 1.23g, m HEDTA : 0.38g, Yin 山梨糖醇 : 0.31g, respectively added to a beaker filled with seawater, and stirred with a glass rod to make it completely dissolved; (3) Weigh Add in the above solution, after it is completely dissolved, measure its pH value to be acidic; (4) Slowly add anhydrous Na to the solution 2 C0 3 And keep stirring, when its pH=8, it will be made into seawater absorption liquid. The experimental conditions for evaluating the desulfurization activity of the seawater absorption liquid are as follows: the volume flow rate of raw gas v=600ml / min, the initial pH value of the absorption liquid is 8, The excess air factor ε is 60. The desulfurization effect at different temperatures is as follows: figure 2 and image 3 shown. Depend on figure 2 and image 3 It can be seen that low temperature favors H 2 Rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com