Electric bag composite dust remover and processing method thereof

A technology of electric bag compounding and processing methods, applied in the direction of chemical instruments and methods, separation methods, combined devices, etc., can solve problems such as poisonous gas and threaten the life safety of operators, and achieve the effect of overcoming toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

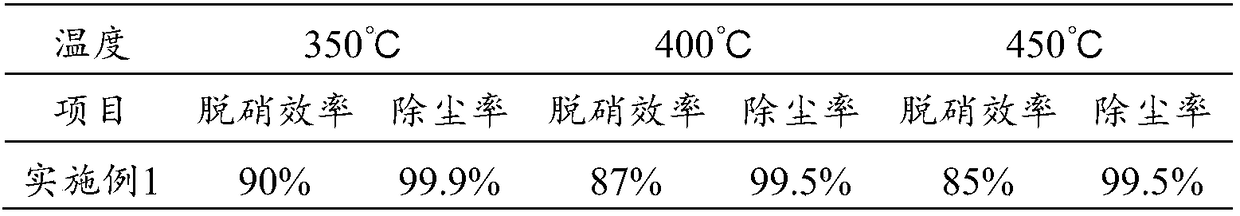

Embodiment 1

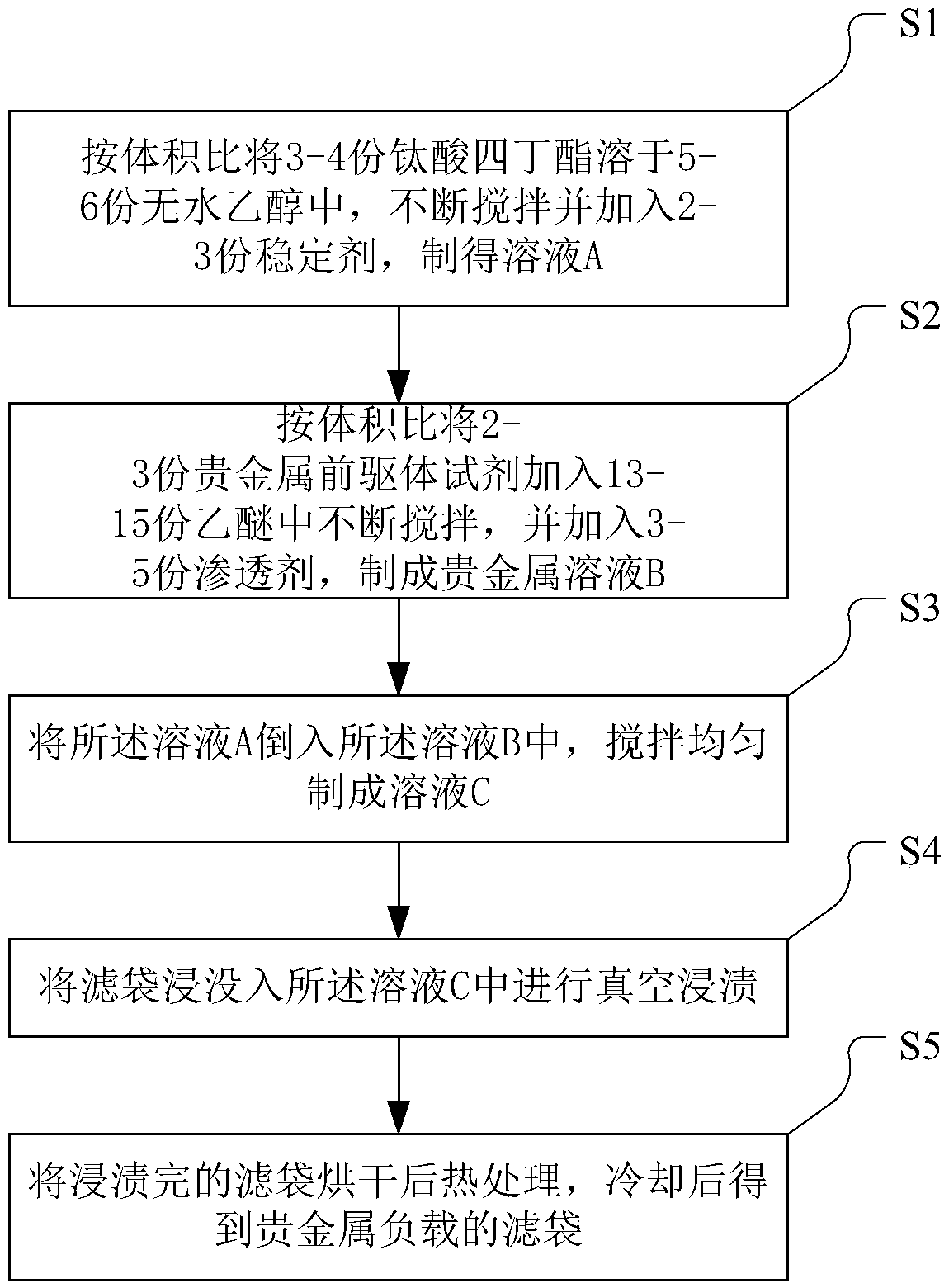

[0047] This embodiment discloses a processing method of an electric bag composite dust collector, the method comprising:

[0048] Step 1. Weigh 3 parts of tetrabutyl titanate, 6 parts of absolute ethanol and 2 parts of stabilizer by volume and stir for 15 minutes to prepare solution A;

[0049] Step 2. Weigh 2 parts of palladium chloride reagent and 15 parts of diethyl ether for rapid stirring, add 3 parts of penetrant during stirring, and stir for 15 minutes to prepare solution B;

[0050] Step 3. Pour solution A into solution B and stir continuously for 20 minutes to prepare solution C;

[0051] Step 4. Immerse the filter bag in solution C, and carry out vacuum impregnation, the vacuum pressure is 500Pa, the immersion time is 1.5 hours, and the number of immersion times is 8 times;

[0052] Step 5. Dry the impregnated filter bag in an oven at 100°C for 12 hours, then place it in air at 400°C for heat treatment for 2 hours, and finally cool it down to room temperature to prepa...

Embodiment 2

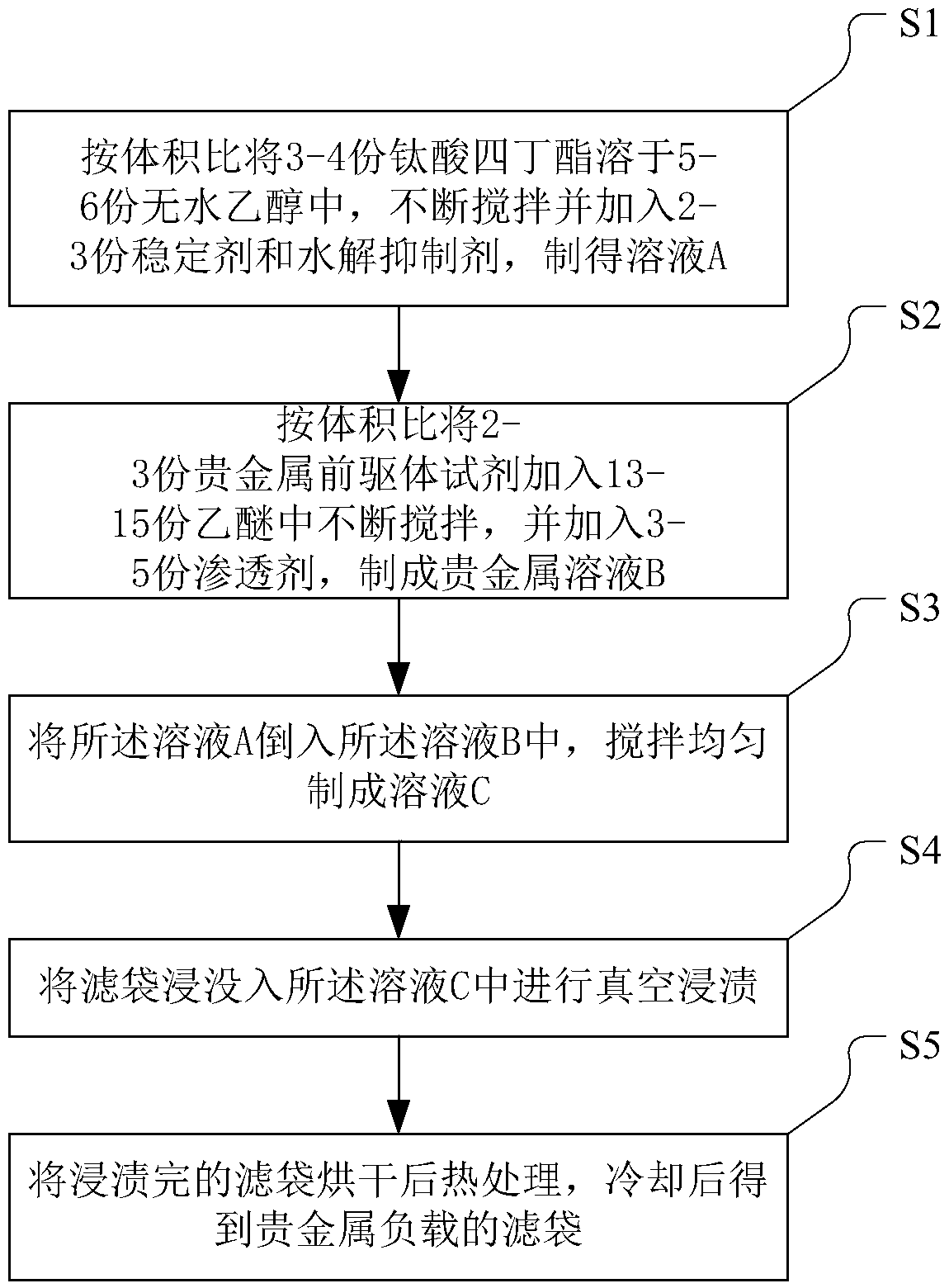

[0058] This embodiment discloses a processing method of an electric bag composite dust collector, the method comprising:

[0059] Step 1. Weigh 4 parts of tetrabutyl titanate, 5 parts of absolute ethanol and 3 parts of stabilizer by volume and stir for 18 minutes to prepare solution A;

[0060] Step 2. Weigh 3 parts of nano-platinum solution and 13 parts of diethyl ether for rapid stirring, add 5 parts of penetrant during the stirring process, and stir for 20 minutes to prepare solution B;

[0061] Step 3. Pour solution A into solution B and stir continuously for 25 minutes to prepare solution C;

[0062] Step 4. Immerse the filter bag in solution C, and carry out vacuum impregnation, the vacuum pressure is 500Pa, the immersion time is 3 hours, and the number of immersion times is 8 times;

[0063] Step 5. Dry the impregnated filter bag in an oven at 100°C for 12 hours, then place it in air at 400°C for heat treatment for 2 hours, and finally cool it down to room temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com