Mineral fiber reinforced environment-friendly building board and preparation method thereof

A mineral fiber and building board technology, applied in the field of green building design, can solve the problems of organic thermal insulation materials such as easy combustion, poor water absorption and freeze-thaw cycles, and high energy consumption for firing ceramic plates, so as to achieve the performance of not being easily damaged, cracked, and stable Excellent, the effect of improving the flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

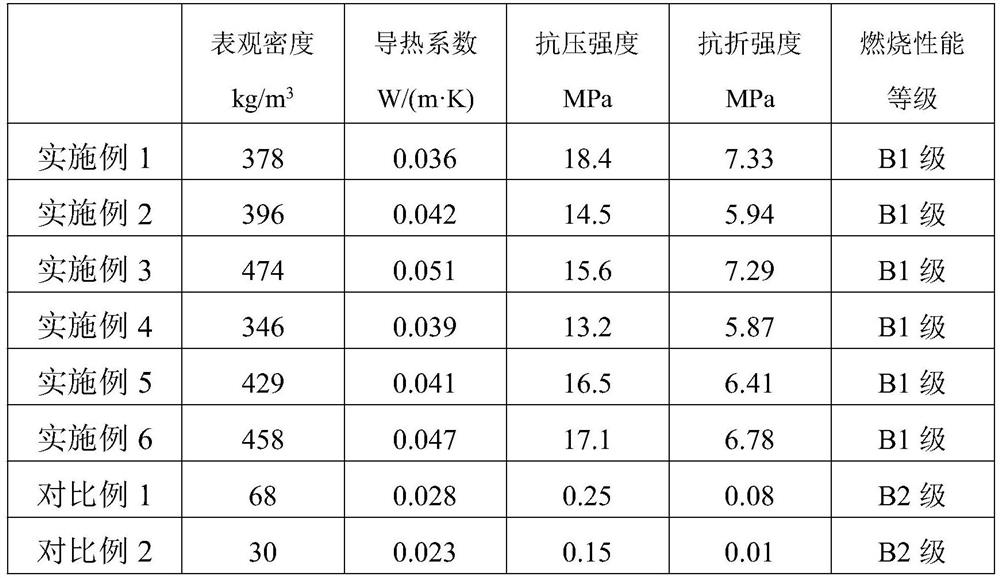

Examples

Embodiment 1

[0056] A mineral fiber reinforced environmental protection building board and a preparation method thereof, the preparation method comprising the following steps:

[0057] S1, take the particle size D 50 6 parts of wollastonite fibers with a diameter of 350nm and an aspect ratio of 18:1, particle size D 50 6 parts of sepiolite fibers with a diameter of 430nm and an aspect ratio of 45:1, particle size D 50 6 parts of attapulgite fibers with a diameter of 380nm and an aspect ratio of 15:1, particle size D 50 6 parts of palygorskite fibers with a diameter of 400nm and an aspect ratio of 25:1; Mg(OH) 2 Mass content 98%, particle size D 50 7 parts of 200nm magnesium hydroxide and 2 parts of phosphoric acid with a concentration of 0.5 mol / L were ground and kneaded for 40 minutes.

[0058] S2, take the bulk density as 180kg / m 3 6 parts of expanded perlite and 2 parts of isocyanate propyltriethoxysilane were added to the materials in step S1, mixed for 12 minutes, and heated to 1...

Embodiment 2

[0065] A mineral fiber reinforced environmental protection building board and a preparation method thereof, the preparation method comprising the following steps:

[0066] S1, take the particle size D 50 350nm, 20 parts of wollastonite fiber with aspect ratio of 15:1, particle size D 50 350nm, 4 parts of sepiolite fiber with aspect ratio of 15:1, particle size D 50 3 parts of attapulgite fibers with a length of 350nm and an aspect ratio of 15:1; Mg(OH) 2 Mass content 98%, particle size D 50 7 parts of 200nm magnesium hydroxide and 1 part of phosphoric acid were ground and kneaded for 35 minutes.

[0067] S2, take the bulk density as 150kg / m 3 6 parts of expanded perlite and 1 part of isocyanate propyltriethoxysilane were added to the material in step S1, mixed for 10 minutes, and heated to 105°C.

[0068] S3. Add 14 parts of phenolic resin and 25 parts of epoxy resin to the heated material in step S2, and stir for 14 minutes, so that the resin is uniformly coated on the s...

Embodiment 3

[0074] A mineral fiber reinforced environmental protection building board and a preparation method thereof, the preparation method comprising the following steps:

[0075] S1, take the particle size D 50 350nm, 20 parts of wollastonite fiber with aspect ratio of 15:1, particle size D 50 350nm, 12 parts of sepiolite fiber with aspect ratio of 15:1, particle size D 50 350nm, 12 parts of palygorskite fiber with aspect ratio of 15:1; Mg(OH) 2 Mass content 98%, particle size D 50 5 parts of 220nm magnesium hydroxide and 1 part of phosphoric acid were ground and kneaded for 30 minutes.

[0076] S2, take the bulk density as 100kg / m 3 6 parts of expanded perlite and 1 part of isocyanate propyltriethoxysilane were added to the material in step S1, mixed for 12 minutes, and heated to 120°C.

[0077] S3. Add 14 parts of phenolic resin and 14 parts of epoxy resin to the heated material in step S2, and stir for 13 minutes, so that the resin is evenly coated on the surface of the inorg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com