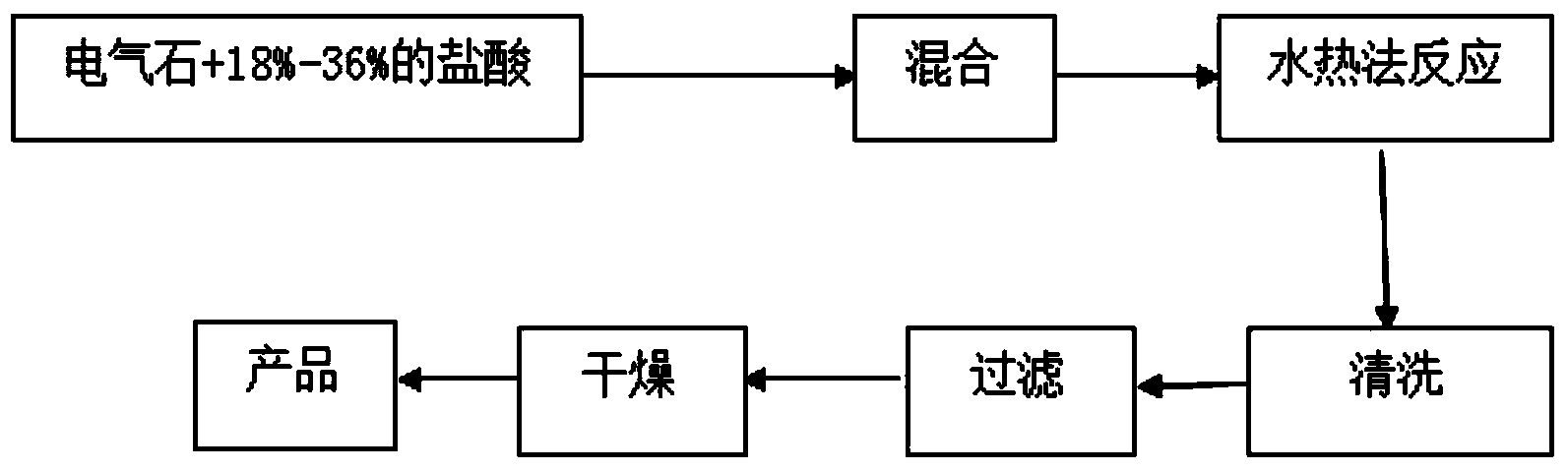

Method for whitening tourmaline powder by using hydrothermal method

A technology of tourmaline powder and hydrothermal method, applied in aluminum silicate, silicate and other directions, can solve the problems of low whiteness and dark color, and achieve the effect of improving quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) First crush the tourmaline to a particle size of 5-45 μm;

[0022] (2) Then mix the pulverized tourmaline powder with hydrochloric acid with a mass concentration of 18-36%, and the mass ratio of tourmaline powder to hydrochloric acid is 1:2;

[0023] (3) Then place it in a closed acid-resistant reaction kettle for heating, using an acid-resistant alloy bushing, the heating temperature is 650 ° C, and the reaction time is 12 hours;

[0024] (4) After the reaction, the reactant is taken out from the reactor, washed and dried to obtain a finished product with a whiteness of 55.

Embodiment 2

[0026] (1) First crush the tourmaline to a particle size of 1-5μm;

[0027] (2) Then mix the pulverized tourmaline powder with hydrochloric acid with a mass concentration of 18-36%, and the mass ratio of tourmaline powder to hydrochloric acid is 1:5;

[0028] (3) Then place it in a closed acid-resistant reaction kettle for heating, using an enamel bushing, the heating temperature is 200°C, and the reaction time is 48h;

[0029] (4) After the reaction is finished, the reactant is taken out from the reaction kettle, washed and dried to obtain a finished product with a whiteness of 50-60.

Embodiment 3

[0031] (1) First crush the tourmaline to a particle size of 600-1000nm;

[0032] (2) Then mix the pulverized tourmaline powder with hydrochloric acid with a mass concentration of 18-36%, and the mass ratio of tourmaline powder to hydrochloric acid is 1:3;

[0033] (3) Then put it in a closed acid-resistant reaction kettle for heating, using enamel bushing, the heating temperature is 400°C, and the reaction time is 30h;

[0034] (4) After the reaction is finished, the reactant is taken out from the reaction kettle, washed and dried to obtain a finished product with a whiteness of 50-65.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com