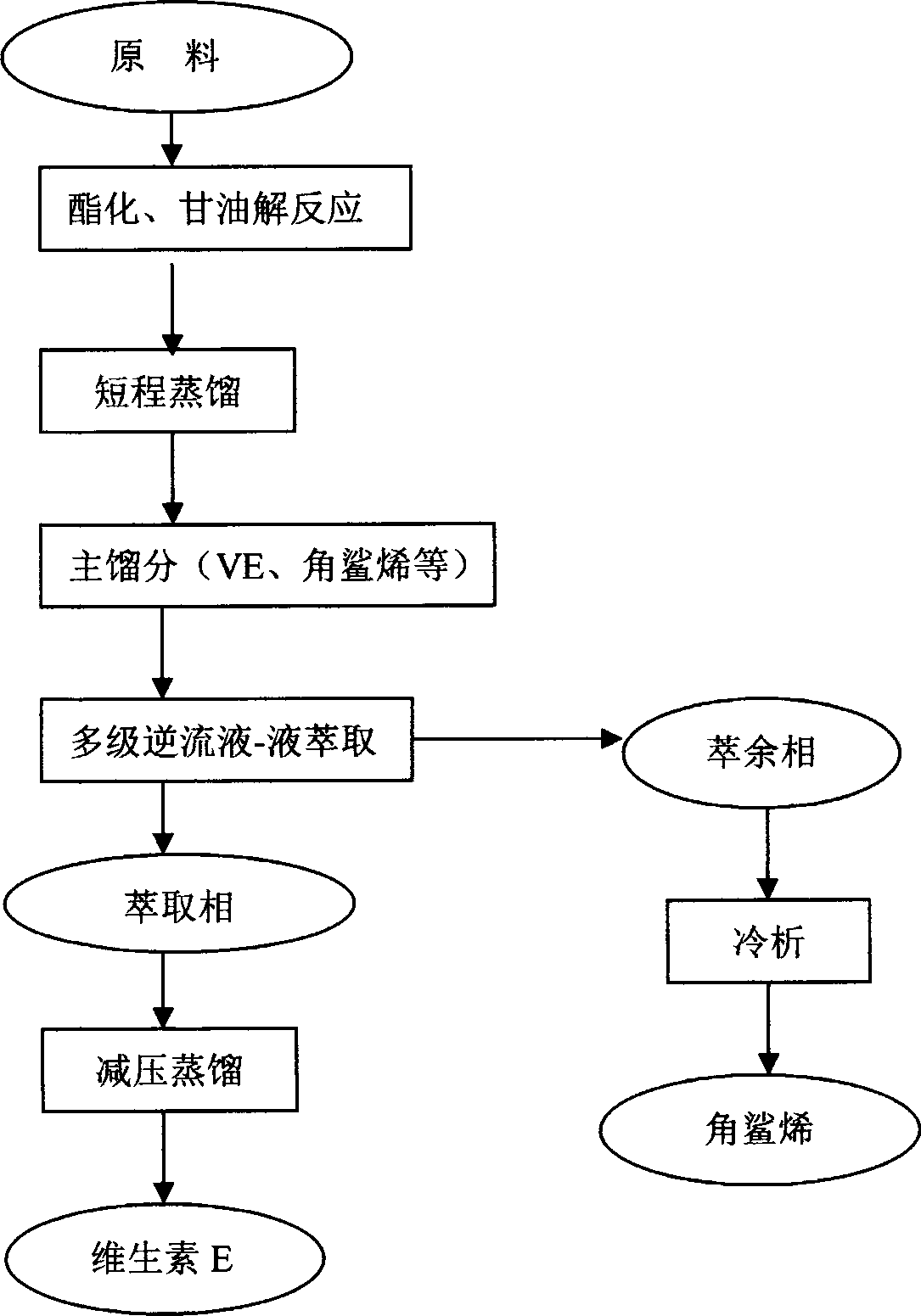

Novel technology for extracting vitamin E and squalene by employing multi-stage counter-current liquid-liquid extraction method

A technology of squalene and vitamins, applied in the direction of extraction and purification/separation, purification/separation of hydrocarbons, chemical instruments and methods, etc., can solve problems such as product yields not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Soybean oil deodorized distillate 65g, acid value 69, vitamin E 7.3%, squalene 1.8%, phytosterol 9.5%. (1), add raw material in the flask with condenser tube, add methanol 360ml, concentrated H 2 SO 4 1.0ml, react at reflux temperature for 2 hours. Then add 180ml of deionized water, separate the methanol water phase, wash the oil phase with 30% deionized water containing methanol until neutral; degas at 10mbar and 100°C for 30 minutes to obtain 660g of methyl esterified sample. (2). Add the methyl esterified sample into a flask with a condenser tube, add 25 g of glycerol and 1.5 g of NaOH, and react at 10 mbar and 210° C. for 4 hours to convert the methyl ester into glyceride. (3). Transfer the above sample to a batch-type short-path distillation device. First, under the conditions of 150-180°C and 50-100Pa, distill out 22.6g of the former fraction with a lower boiling point; Continue distillation under the condition, collect main distillate 85.5g, wherein vitamin E...

Embodiment 2

[0017] Rice bran oil deodorized distillate 500g, acid value 110, vitamin E 6.2%, squalene 3.1%, phytosterol 10.5%. (1), add raw material in the flask with condenser tube, add methanol 200ml, concentrated H 2 SO 4 0.75ml, reacted at reflux temperature for 3 hours. Then add 100ml of deionized water, separate the alcoholic water phase, wash the oily phase with deionized water containing 30% methanol until neutral; degas at 20mbar and 100°C for 45 minutes to obtain 510g of methyl esterified sample. (2) Add the raw material for methyl esterification into a flask with a fractionation condenser, add 30 g of glycerol and 1.0 g of NaOH, and react at 10 mbar at 210° C. for 5 hours to convert the methyl ester into glyceride. (3) Transfer the above sample to a batch-type short-path distillation device. First, under the conditions of 150-180°C and 50-100Pa, distill out 25.0g of the previous fraction with a lower boiling point; then under the conditions of 210-250°C and 1030Pa Continue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com