Air disinfection effect pipeline evaluating system

An evaluation system, air disinfection technology, applied in the field of public health and environmental sanitation, can solve problems such as lack of repeatability, difficult control of microbial aerosol leakage, and potential biological safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

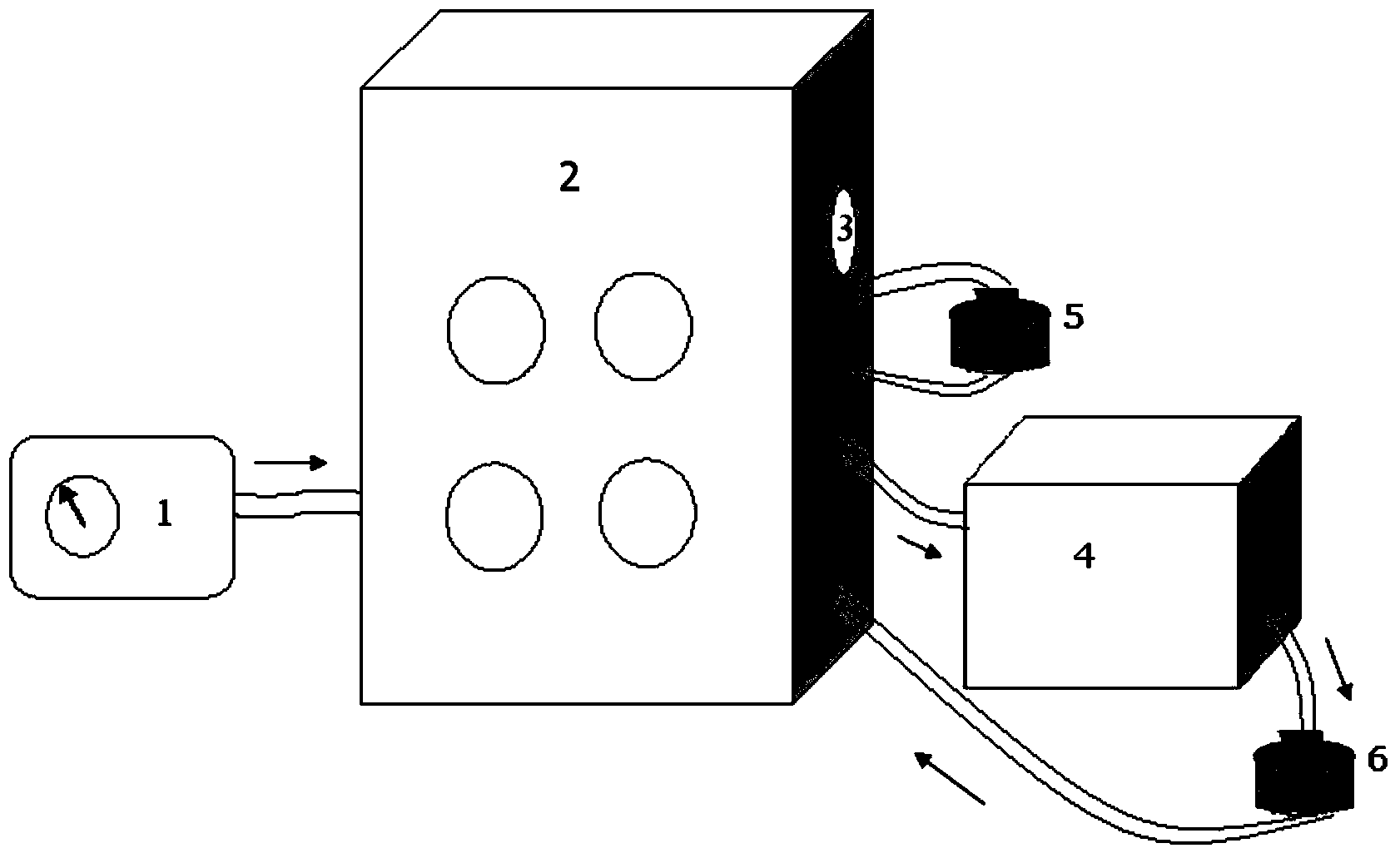

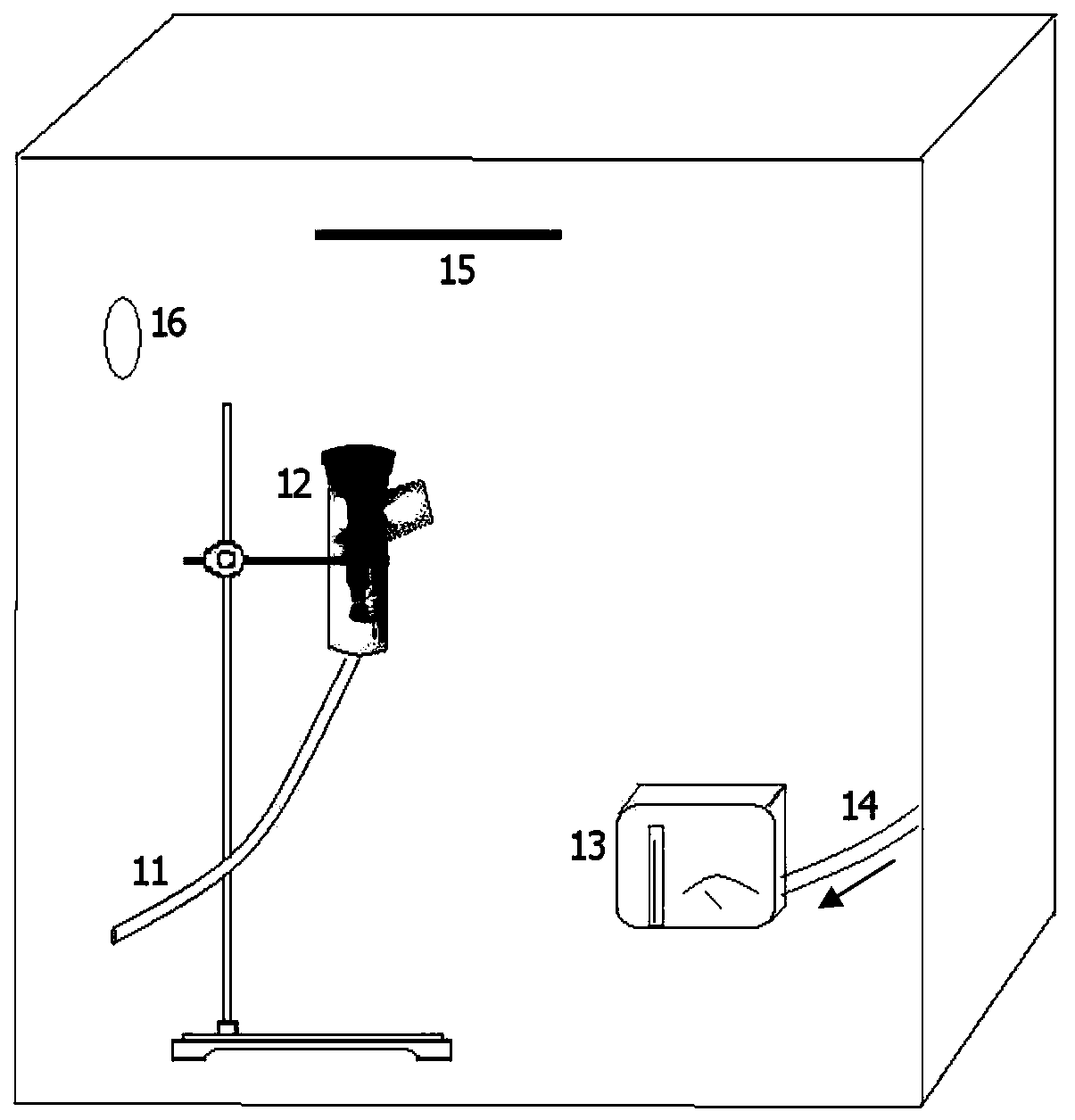

[0039] figure 1In the pipeline evaluation system used to test the transient disinfection effect of the air purifier, the integration method of the microbial aerosol generating equipment, the airtight cabinet containing the microbial aerosol, the air purifier to be tested and two samplers is shown. The sampler I and the airtight cabinet independently form a closed circuit; the aerosol in the airtight cabinet flows back into the cabinet after passing through the air purifier and sampler II, and the arrow indicates the flow direction of the aerosol. figure 2 Indicates the main components inside the airtight cabinet, including the atomization cup and its bracket containing the atomization liquid, the air pump of the sampler I, and the ultraviolet lamp used for disinfection in the cabinet before and after the experiment and other auxiliary equipment. The arrow indicates that the aerosol passes outside the cabinet The air cleaner and sampler II flow back into the cabinet.

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com