Method for processing saturated overwet soil foundation for prespud operation by using graded construction slag soilbag

A technology of dregs and bags, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of a large amount of sand and gravel, difficult construction, long construction period, etc., and achieve the goal of reducing landfill, shortening construction period, and fewer processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

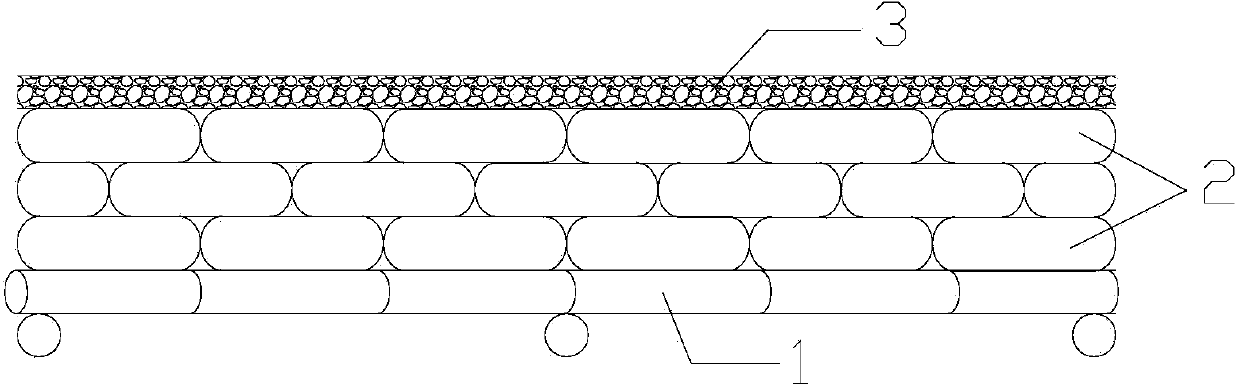

[0021] The overall design diagram of the present invention is as follows figure 1 shown, according to figure 1 The design, its specific scheme is as follows:

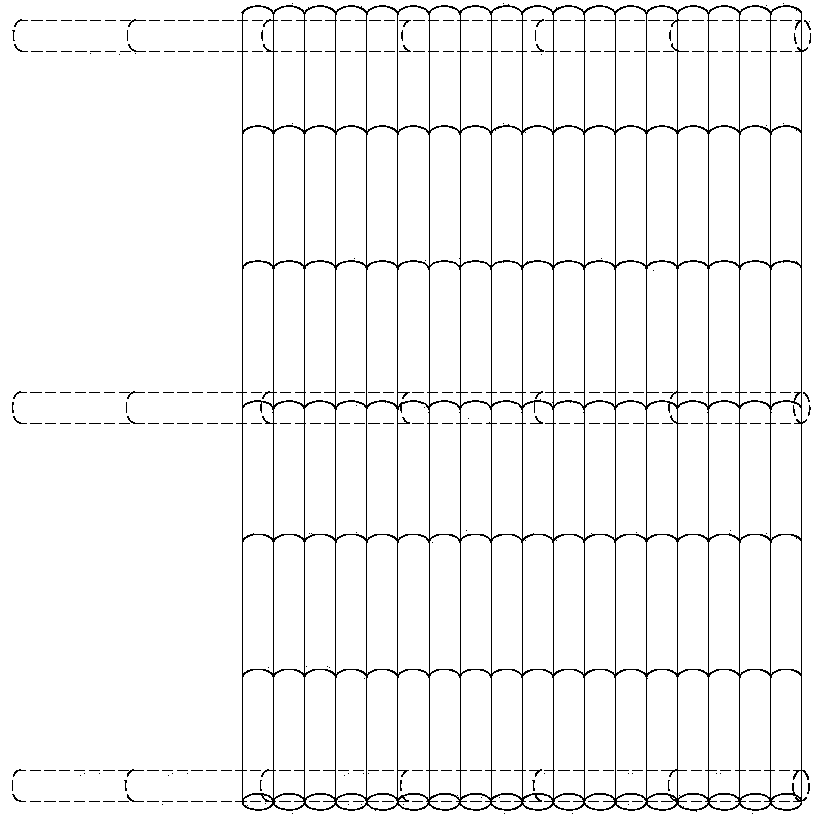

[0022] a) Use a light backhoe excavator and a light loader to level out a site, set a layer of bamboo rafts on the surface of the site, lay three bamboos perpendicular to the direction of the road, with a distance of 1m, lay bamboo continuously along the direction of the road, and fix them with bamboo strips (such as figure 2 shown), and then manually step on it to make the bamboo raft fully contact with the weak foundation;

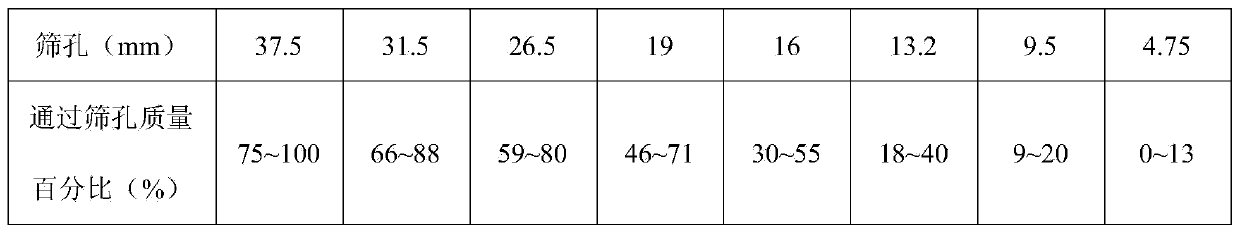

[0023] b) Use a crusher to crush the waste concrete and waste bricks to less than 4cm, and then put the waste concrete blocks and waste bricks into geotechnical bags according to the mass ratio of 70:30 according to the particle size requirements in Table 1 to form graded building slag Geobags;

[0024] c) Lay graded construction slag geobags on the bamboo rafts, lay three layers with staggere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com