Wear-resistant anticorrosive sucker-rod coupling

A sucker rod coupling, mass percentage technology, applied in drill pipe, drilling equipment, earthwork drilling, etc. The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

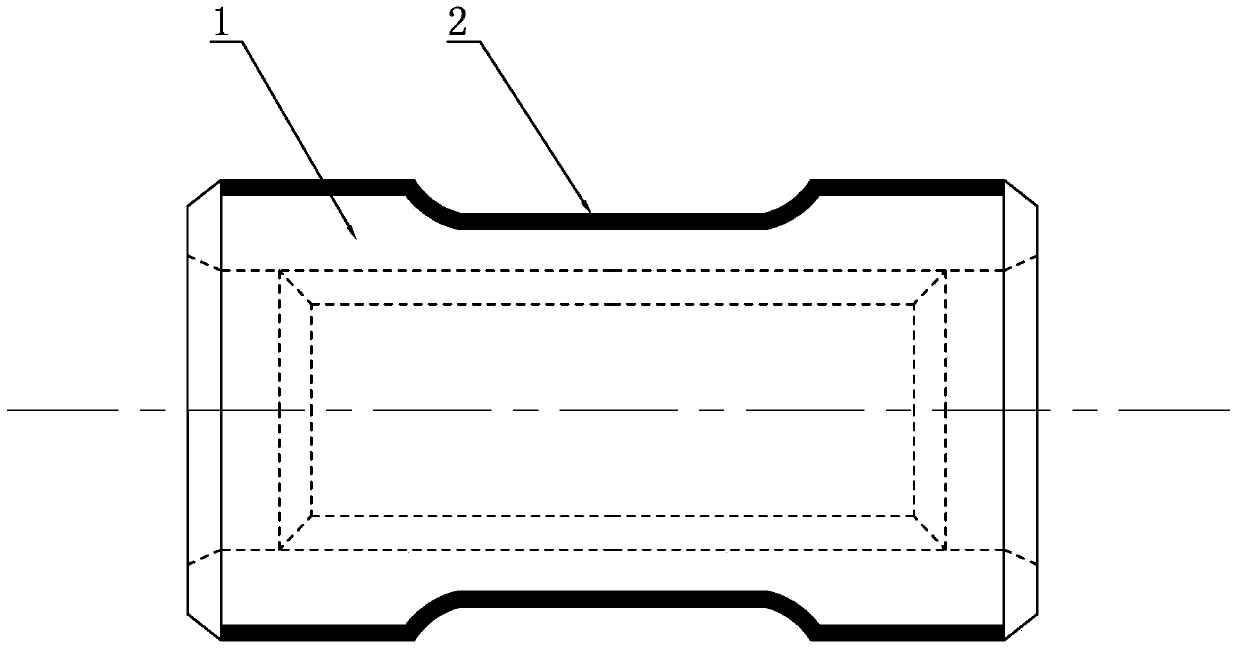

Image

Examples

Embodiment 1

[0033] Embodiment 1: In terms of mass percentage, the composition of the nickel-based alloy powder is selected as: C: 0.2%, Si: 2%, B: 5%, Cr: 23%, Fe: 3.7%, and the balance is nickel . In terms of mass percentage, the composition of the matrix 1 is selected as: C: 0.1%, Si: 0.4%, Mn: 0.7%, Cr: 2%, Mo: 0.6%, Ni: 0.6%, P: 0.025%, S: 0.025%, the balance is iron.

Embodiment 2

[0034] Embodiment 2: In terms of mass percentage, the composition of the nickel-based alloy powder is selected as: C: 0.3%, Si: 3%, B: 6%, Cr: 16%, Fe: 4%, and the balance is nickel . In terms of mass percentage, the composition of the matrix 1 is selected as: C: 0.13%, Si: 0.8%, Mn: 1.0%, Cr: 2.5%, Mo: 0.2%, Ni: 0.2%, P: 0.025%, S: 0.025%, the balance is iron.

Embodiment 3

[0035] Embodiment 3: In terms of mass percentage, the composition of the nickel-based alloy powder is selected as: C: 0.5%, Si: 4%, B: 4%, Cr: 19%, Fe: 3.5%, and the balance is nickel . In terms of mass percentage, the composition of the matrix 1 is selected as: C: 0.16%, Si: 1.2%, Mn: 0.4%, Cr: 1.5%, Mo: 0.4%, Ni: 0.4%, P: 0.025%, S: 0.025%, the balance is iron.

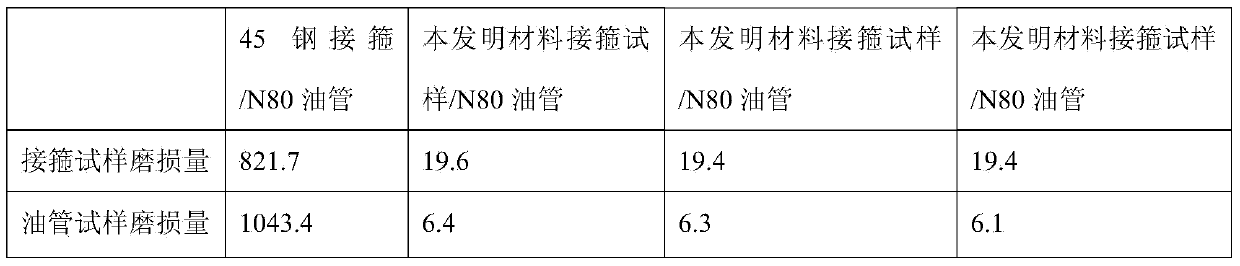

[0036] Secondly, under experimental conditions, the sample spray welding layer 2 in the above three embodiments is tested for corrosion and wear performance, and three 45 steel coupling samples are selected to test corrosion resistance and wear resistance, and then the present invention Corrosion resistance and wear resistance were compared and evaluated.

[0037] Corrosion resistance test The experimental process and results are as follows: the corrosion test was carried out in HCl solution with a concentration of 1mol / L and NaCl solution with a concentration of 3.5%, and the samples were soaked continuously for 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com