LED fluorescent lamp based on continuous spectrum fluorescent powder

A technology for LED fluorescent lamps and LED light sources, applied in the fields of semiconductor lighting and luminescent materials, can solve the problems of light color mismatch, affecting visual effects, glare, etc., to improve stability and service life, reduce fluorescence quenching effect, and reduce overall The effect of reflection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

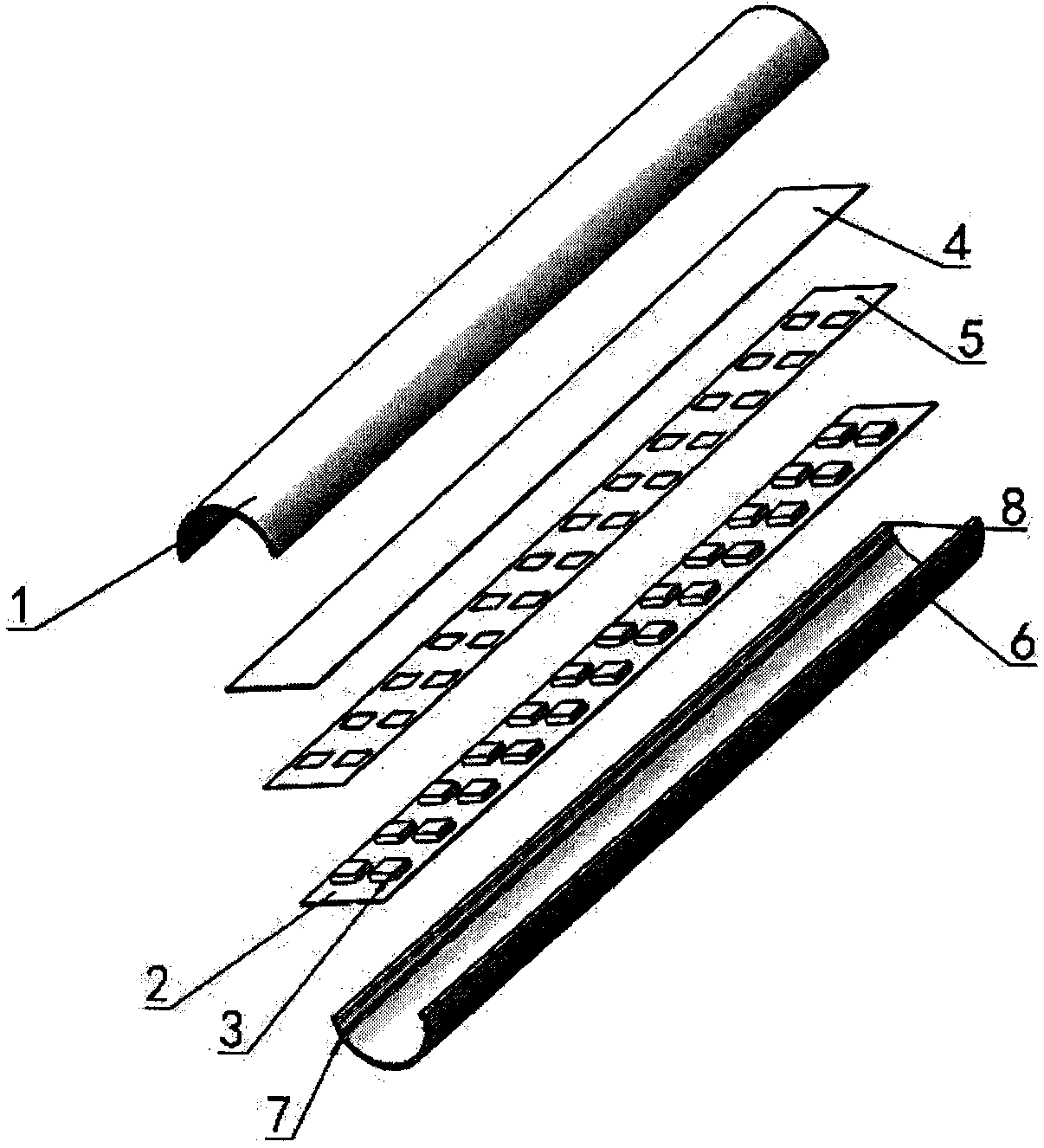

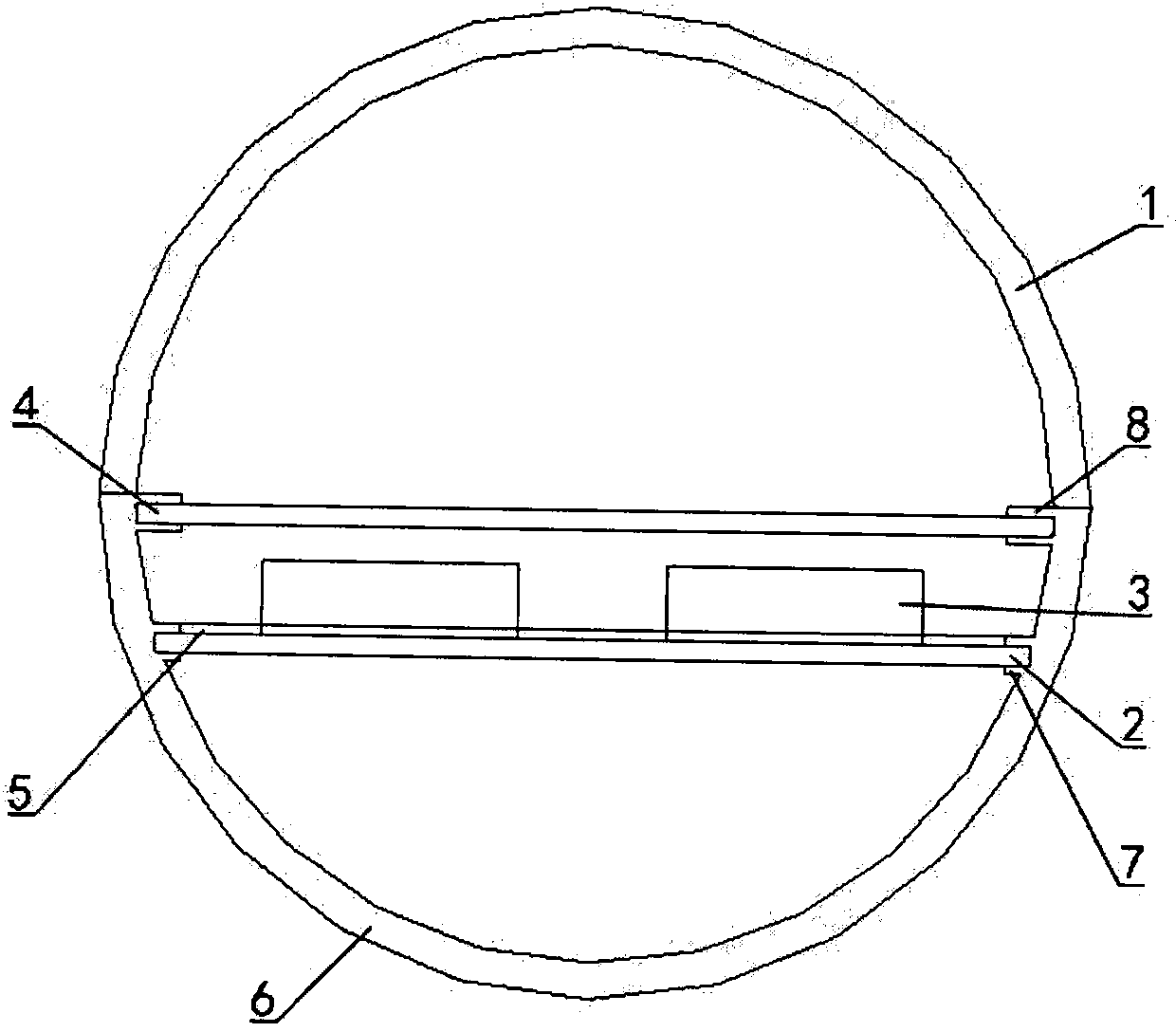

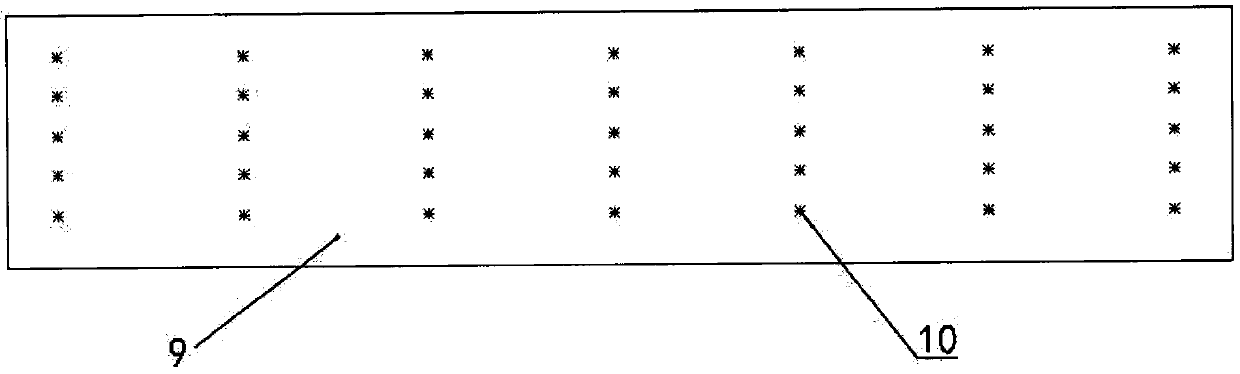

[0028] 1. Select a single LED light source (3) as the excitation light source, and fix it on the substrate (2) with thermally conductive adhesive; 2. Select a continuous spectrum phosphor (10) with a central particle size of 16 μm and a matrix material (9 ), prepare the fluorescent conversion device (4) by hot pressing; 3, carry out molding roughening treatment on the surface of the fluorescent conversion device; 4, combine the substrate (2) with the substrate bayonet (7), and the fluorescent conversion device (4 ) is placed on the top of the light source (3) in combination with the fluorescent conversion device bayonet (8) in a way away from the light source (3), and the MCPET optical reflection film (5) is closely attached to the surface of the substrate (2) to obtain a based on The continuous spectrum phosphor has high light utilization rate, high color rendering index, uniform light color, high reliability and low cost LED fluorescent lamp.

Embodiment 2

[0030] 1. Select an integrated packaged LED light source (3) as the excitation light source, and fix it on the substrate (2) with thermally conductive adhesive; 2. Select a continuous spectrum phosphor (10) with a central particle size of 17 μm and a base material (9 ), preparing the fluorescent conversion device (4) by injection molding; 3, performing dry etching roughening treatment on the surface of the fluorescent conversion device; 4, combining the substrate (2) with the substrate bayonet (7), and the fluorescent conversion device (4) Place it on the upper part of the light source (3) in combination with the fluorescent conversion device bayonet (8) in a way away from the light source (3), and the MCPET optical reflection film (5) is closely attached to the surface of the substrate (2) to obtain a An LED fluorescent lamp with high light utilization rate, high color rendering index, uniform light color, high reliability and low cost based on continuous spectrum phosphor.

Embodiment 3

[0032] 1. Select a single LED light source (3) as the excitation light source, and fix it on the substrate (2) with thermally conductive adhesive; 2. Select a continuous spectrum phosphor (10) with a central particle size of 18 μm and a matrix material (9 ), prepare the fluorescent conversion device (4) by spraying; 3, carry out molding roughening treatment on the surface of the fluorescent conversion device; 4, combine the substrate (2) with the substrate bayonet (7), and the fluorescent conversion device (4) Combining with the bayonet (8) of the fluorescent conversion device and placing it on the upper part of the light source (3) in a way far away from the light source (3), the mirror-surface aluminum optical reflection film (5) is closely attached to the surface of the substrate (2) to obtain a The continuous spectrum phosphor has high light utilization rate, high color rendering index, uniform light color, high reliability and low cost LED fluorescent lamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com