Method for measuring corrosion performance of descaling agent

A measurement method and corrosion performance technology, which is applied in the field of determination of the corrosion performance of descaling agents, can solve problems such as the adverse effects of phosphorus compounds on the ecological environment, and achieve the effects of reducing test costs, simple test steps, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

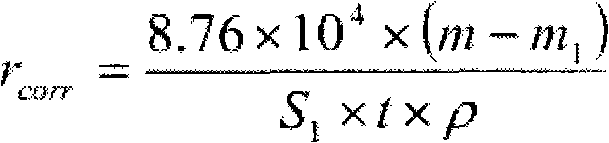

Image

Examples

Embodiment

[0026] A kind of measuring method of corrosion performance of descaling agent that the present invention relates to, comprises the following steps:

[0027] (a) First, according to the requirements of the experiment, use a volumetric flask to prepare the acid descaling agent solution and the corrosion inhibitor solution, and the solution will be prepared on the day of the experiment;

[0028] (b) Then, wipe the test piece with filter paper first, then put it into a container filled with acetone with a boiling range of 60-90°C, remove the grease on the surface of the test piece with absorbent cotton, and then soak it in absolute ethanol for 5 minutes , further degreasing and dehydration; take out the test piece and put it on the filter paper, dry it with cold air, then wrap the test piece with filter paper, store it in a desiccator, take it out after standing for 1 hour, measure the size and weigh it, accurate to 0.1mg;

[0029] (c) Add the prepared acid descaling agent solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com