Stepless speed regulation device for working table or spindle of numerical control machine tool

A technology of stepless speed regulation for numerically controlled machine tools, applied in fields such as excitation or armature current control, can solve the problems of limiting system frequency bandwidth and speed regulation range, runaway time and large dead zone voltage, and restricting the development of the manufacturing industry, etc., to achieve Simple structure, high dynamic hardness, good rapidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

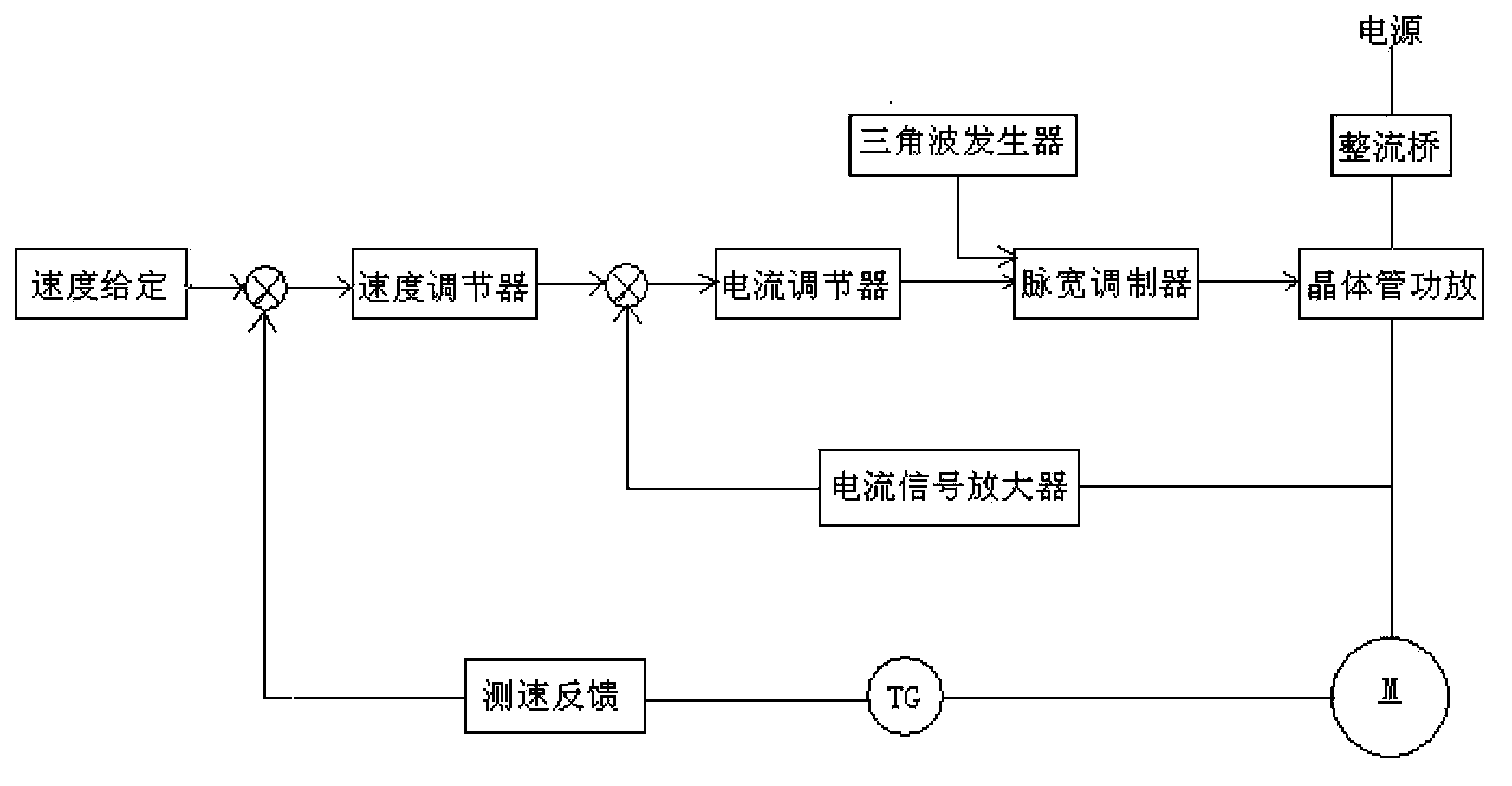

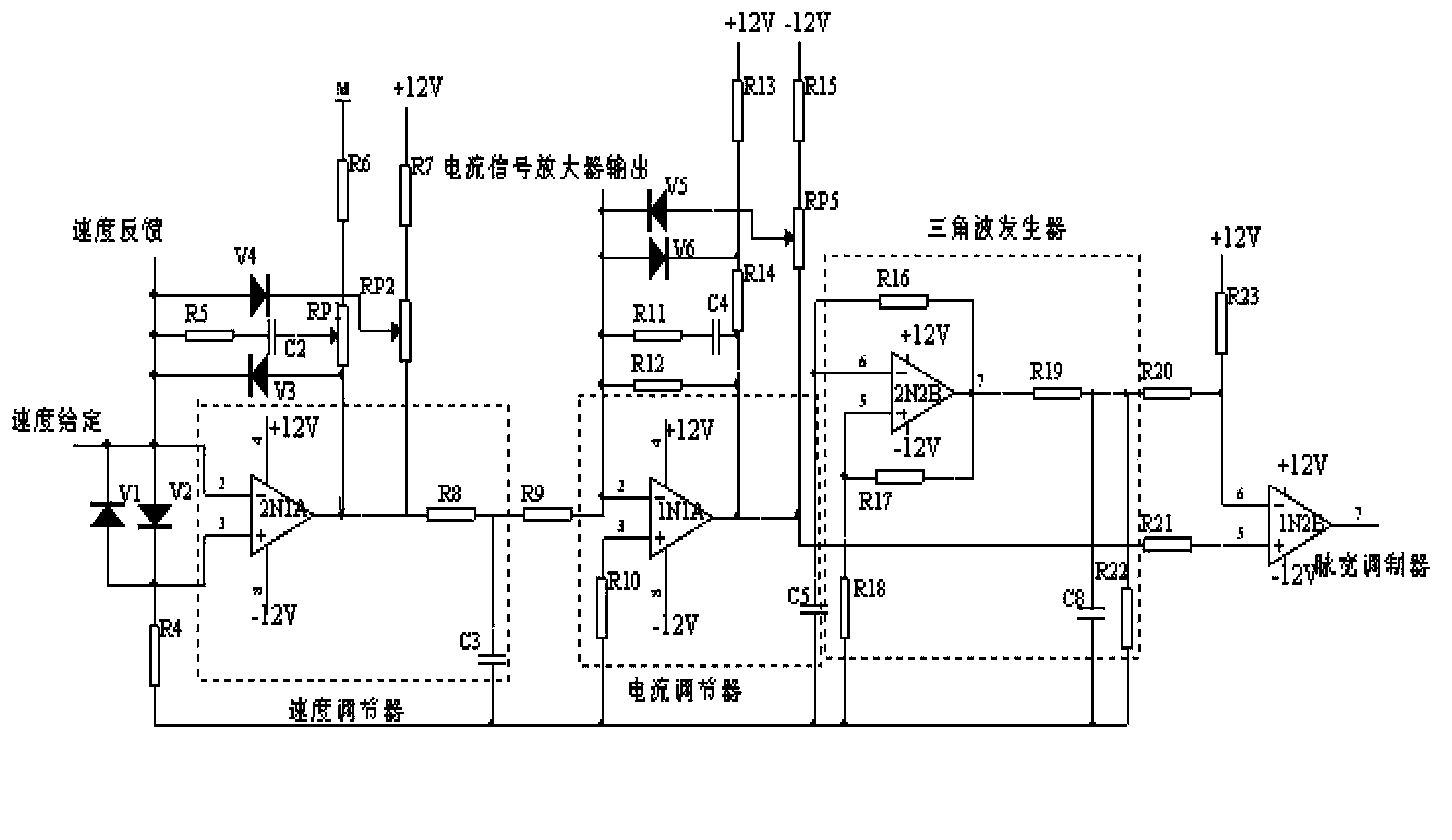

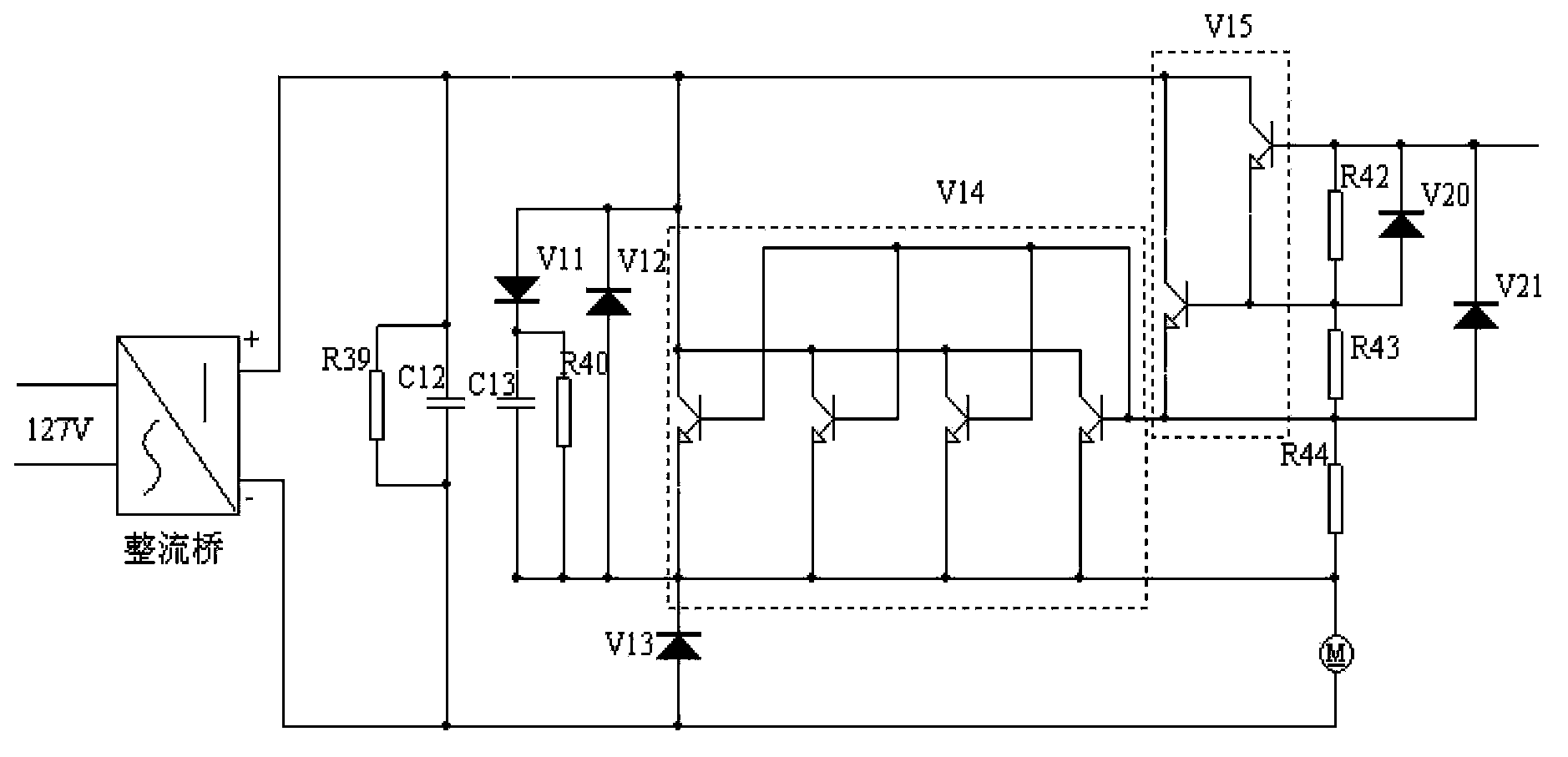

[0027] Such as figure 1 As shown, the structural design of the present invention is realized in this way: the device is a double closed-loop speed regulation system composed of a small current closed loop and a large speed closed loop, which is used to control the speed of the motor. The control loop is composed of a speed regulator, a current regulator, a triangle wave generator, and a pulse width modulator. The main circuit is composed of a rectifier circuit and a transistor power amplifier circuit.

[0028] Its connection is: the power supply unit has a rectification, filter circuit, power supply voltage stabilization circuit, and provides +5V, -5V, +12V, -12V DC power for other functional modules. Both the speed regulator and the current regulator use proportional integral regulators. The two are connected in series. The output of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com