Wire bonding apparatus and wire bonding method

一种引线接合、接合点的技术,应用在焊接设备、半导体/固态器件零部件、半导体/固态器件测试/测量等方向,能够解决接合强度降低、损坏装置、污染超声波喇叭等问题,达到防止热渗透、结构简单化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

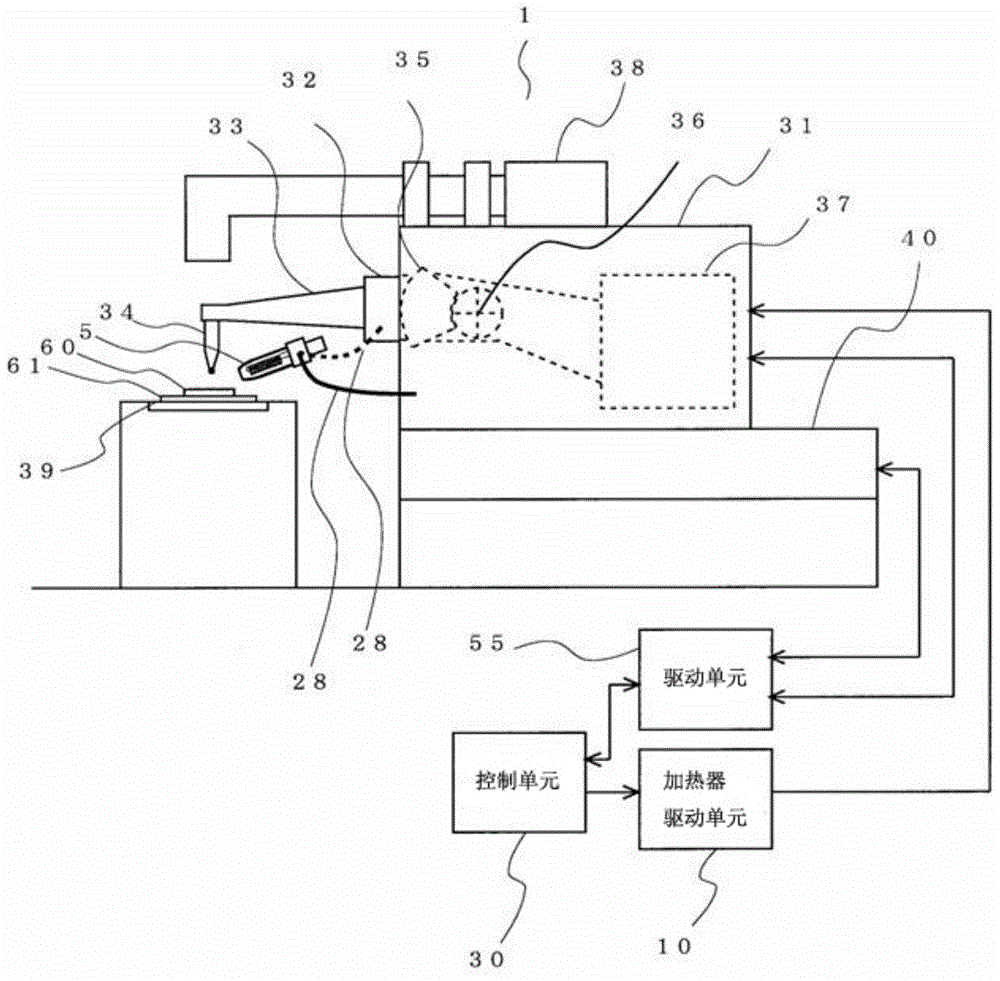

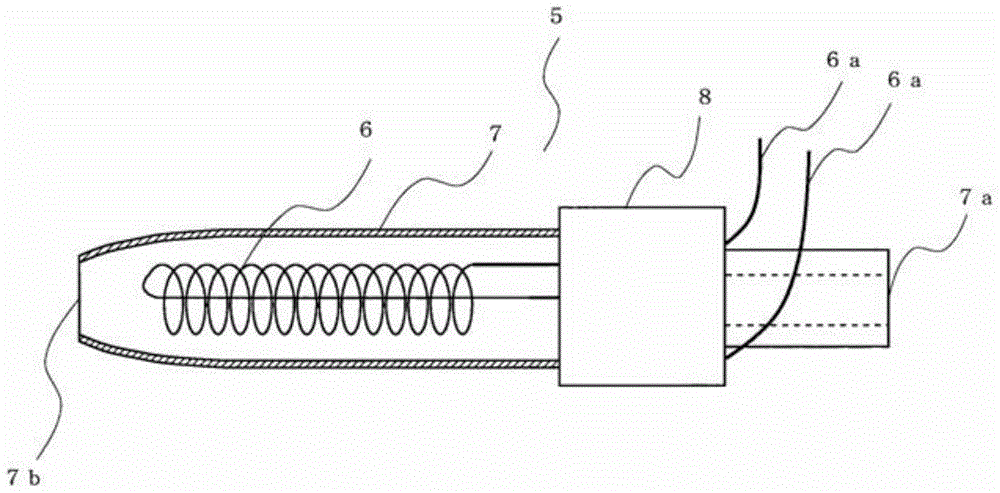

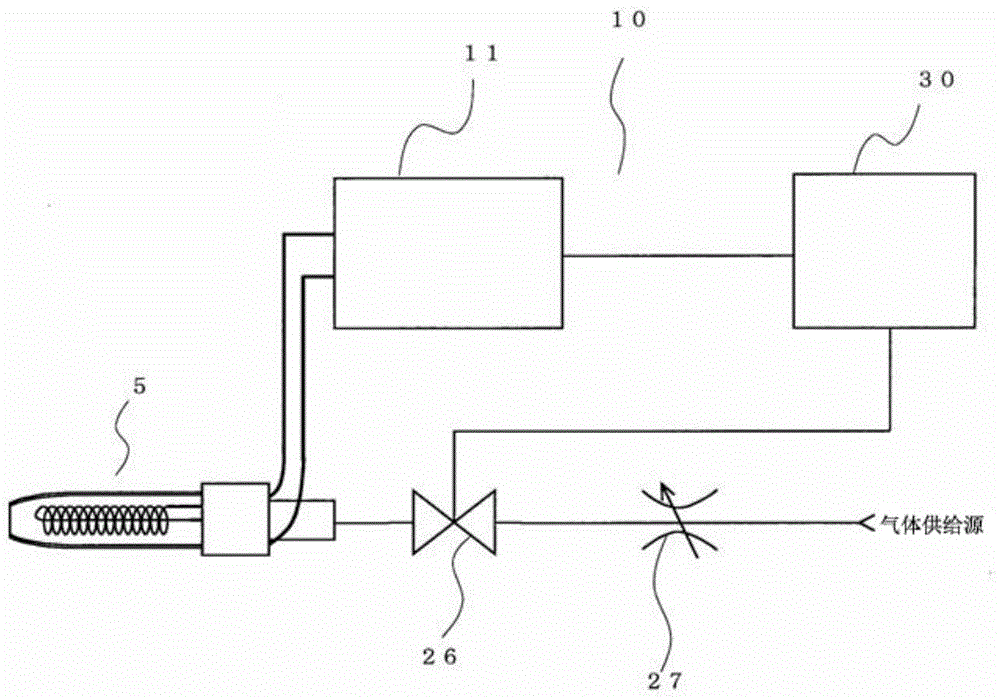

[0044] Embodiments of the wire bonding apparatus and the wire bonding method of the present invention will be described with reference to the following drawings. In addition, the present invention uses heated air or other gas (gas) and other gases that flow out from the ultra-small hot air heater installed on the bonding head or the bonding arm to heat the chips, substrates (lead frames), and balls (balls). ), the bonding tool or the bonding wire is heated, and the heated air or gas is supplied for a limited time in the necessary heating area for bonding, thereby improving the bonding performance, reducing the adverse effects of heating with the existing heating plate, and improving production. efficiency and quality.

[0045] The structure of the coupling device

[0046] figure 1 It is a structural schematic diagram of the bonding device of the present invention. Additionally, for Figure 8 The same structural parts of the conventional wire bonding apparatus shown are den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com