Soft fermented coarse pancake and producing method thereof

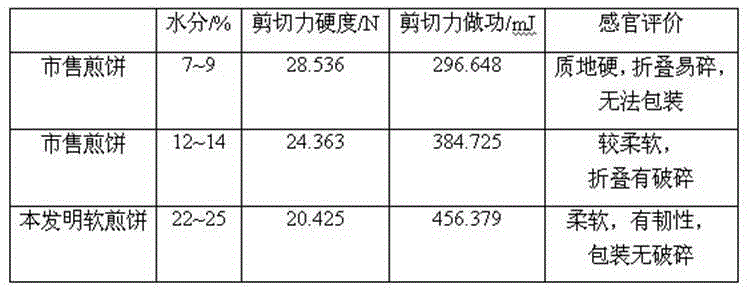

A technology for pancakes and miscellaneous grains, which is applied in the field of miscellaneous grains fermented soft pancakes and their preparation, which can solve the problems of unsuitable stuffing or rolls, poor eating quality, and hard pancakes, so as to achieve a more chewy taste and improve emulsification properties. Effects of stabilization, improvement of elasticity and water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh raw materials: 20kg brown rice, 40kg rice, 23.85kg flour, 10kg soybeans, 0.3kg xanthan gum, 0.2kg carrageenan, 0.2kg sodium bicarbonate, 0.1kg ammonium bicarbonate, 5kg polydextrose, 0.3kg sodium pyrophosphate, 0.05kg sodium dehydroacetate;

[0031] (1) Mix 20kg of brown rice, 40kg of rice, 23.85kg of flour and 10kg of soybeans evenly to obtain mixed raw materials, add 300kg of water to soak for 10 hours; add soaked mixed raw materials to 200kg of water, grind to 100 mesh, and ferment at 28°C for 6 hours. get fermented batter;

[0032] (2) Add 0.3kg of xanthan gum, 0.2kg of carrageenan, 0.2kg of sodium bicarbonate, 0.1kg of ammonium bicarbonate, 5kg of polydextrose, and 0.3kg of coke to the fermented batter prepared in step (1) by weight percentage. Stir sodium phosphate and 0.05kg sodium dehydroacetate evenly, and mix it into miscellaneous grain pancake paste;

[0033] (3) Take 300g of the mixed grain pancake batter, roll it out evenly on a griddle at 180°C to ...

Embodiment 2

[0035] Weigh raw materials: 21.51kg brown rice, 40kg rice, 20kg flour, 15kg soybeans, 0.1kg xanthan gum, 0.3kg carrageenan, 0.1kg sodium bicarbonate, 0.15kg ammonium bicarbonate, 2kg polydextrose, 0.8kg sodium pyrophosphate, 0.04kg sodium dehydroacetate;

[0036] (1) Mix 21.51kg of brown rice, 40kg of rice, 20kg of flour and 15kg of soybeans evenly to obtain mixed raw materials, add 200kg of water to soak for 12 hours; add soaked mixed raw materials to 300kg of water, grind to 140 mesh, and ferment at 32°C for 10 hours. get fermented batter;

[0037] (2) Add 0.1kg of xanthan gum, 0.3kg of carrageenan, 0.1kg of sodium bicarbonate, 0.15kg of ammonium bicarbonate, 2kg of polydextrose, and 0.8kg of coke to the fermented batter prepared in step (1) by weight percentage. Stir sodium phosphate and 0.04kg sodium dehydroacetate evenly, and mix it into miscellaneous grain pancake paste;

[0038] (3) Take 500g of mixed grain pancake batter, roll it out evenly on a griddle at 180°C to f...

Embodiment 3

[0040] Weigh raw materials: 20kg sorghum, 40.73kg rice, 25kg flour, 10kg soybeans, 0.2kg xanthan gum, 0.25kg carrageenan, 0.15kg sodium bicarbonate, 0.12kg ammonium bicarbonate, 3kg polydextrose, 0.5kg sodium pyrophosphate, 0.05kg sodium dehydroacetate;

[0041] (1) Mix 20kg of sorghum, 40.73kg of rice, 25kg of flour and 10kg of soybeans evenly to obtain the mixed raw material, add 250kg of water to soak for 11 hours; add the soaked mixed raw material to 250kg of water, grind to 120 mesh, and ferment at 30°C for 8 hours, get fermented batter;

[0042] (2) Add 0.2kg xanthan gum, 0.25kg carrageenan, 0.15kg sodium bicarbonate, 0.12kg ammonium bicarbonate, 3kg polydextrose, 0.5kg coke to the fermented batter prepared in step (1) by weight percentage Stir sodium phosphate and 0.05kg sodium dehydroacetate evenly, and mix it into miscellaneous grain pancake paste;

[0043](3) Take 400g of the mixed grain pancake batter, roll it out evenly on a griddle at 180°C to form thin pancakes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com