Metallic surface dirt laser cleaning system and method

A technology of laser cleaning and metal surface, which is applied in the field of laser cleaning to achieve the effect of good cleaning effect, reduced energy loss and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

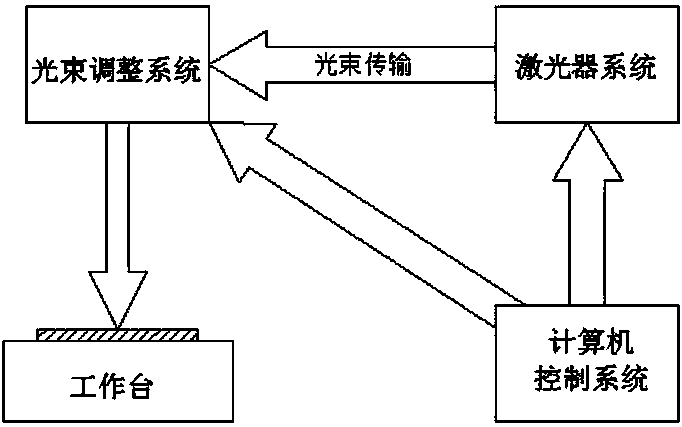

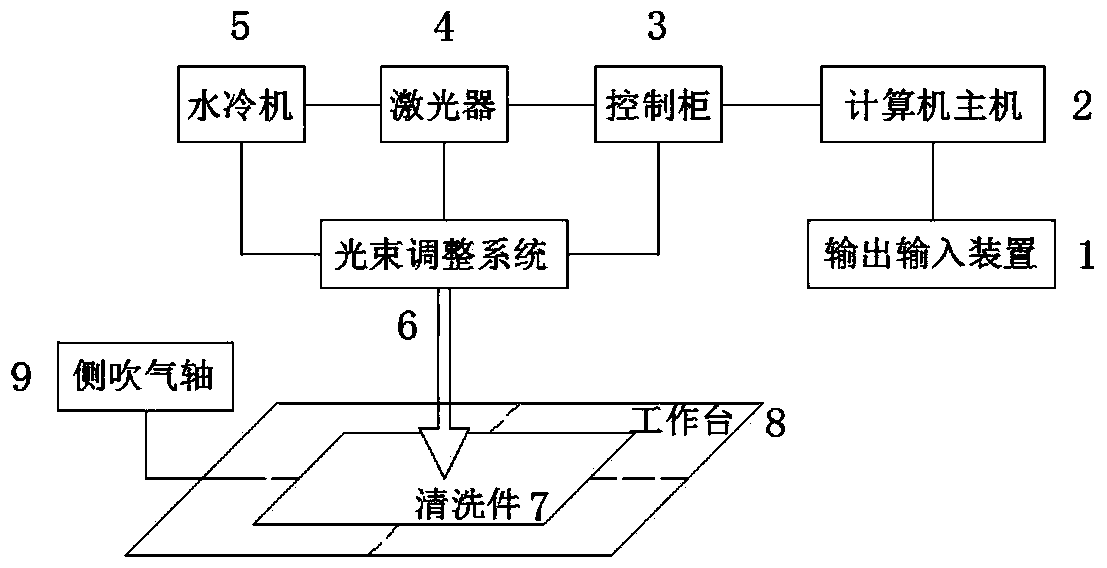

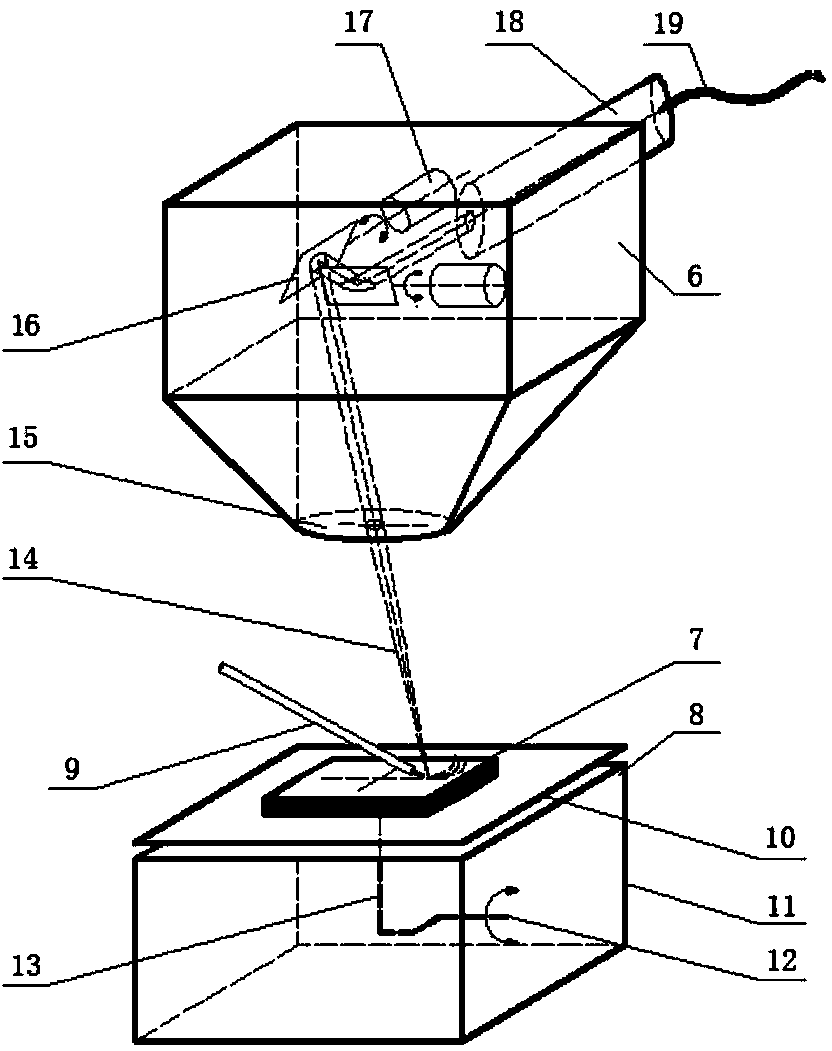

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0046] Example 1: Cleaning of metal paint on the surface of aluminum alloy body

[0047] Continuous laser light emitted by fiber laser

[0048] Paint layer thickness: 0.50mm

[0049] Laser power: 300w

[0050] Cleaning speed: 500mm / s

[0051] Spot diameter: 0.07mm

[0052] Air flow: 3.5m 3 / h

[0053] Under microscopic observation, ≧95% of the paint layer is removed, cleaning efficiency: 115.4mm 2 / s, compared with the existing ultrasonic cleaning efficiency of the same thickness of metal paint layer is generally only 40-50mm 2 / s; In addition, the base material is not damaged after cleaning, and the original bright white color of the aluminum alloy is exposed on the surface, achieving the ideal effect of cleaning.

example 2

[0054] Example 2: Rust layer cleaning on the surface of 45 steel

[0055] Continuous laser light emitted by fiber laser

[0056] Rust layer thickness: 0.45mm

[0057] Laser power: 250w

[0058] Cleaning speed: 500mm / s

[0059] Spot diameter: 0.07mm

[0060] Air flow: 3.0m 3 / h

[0061] Under microscopic observation, ≧95% of the rust layer is removed, cleaning efficiency: 89.8mm 2 / s. The base material is not burned, and the metal color of carbon steel is exposed, achieving the ideal effect of cleaning.

example 3

[0062] Example 3: Cleaning of oil stain layer on stainless steel plate

[0063] Using truncated pulsed laser

[0064] Oil layer thickness: 0.05mm

[0065] Laser power: 200w

[0066] Cleaning speed: 500mm / s

[0067] Spot diameter: 0.07mm

[0068] Air flow: 1.0m 3 / h

[0069] Under microscopic observation, ≧95% of the oil layer is removed, cleaning efficiency: 122.2mm 2 / s. There is no damage to the stainless steel plate, and the original metal color of the stainless steel substrate is exposed, achieving the ideal effect of cleaning.

[0070]Therefore, the metal surface laser cleaning method based on the fiber laser proposed in the present invention breaks the limitation that the power density can only be increased by increasing the power in the early stage, but uses a fiber laser with a small beam diameter and stable quality, and adjusts the beam system to achieve the ideal spot diameter. While increasing the power density, it does not affect the change of heat input...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com