Bamboo reed composite panel and forming method thereof

A composite material board and a molding method technology, which are applied in the field of reed bamboo composite material board and its molding, reed bamboo thermoplastic resin composite material board and its molding field, can solve problems such as poor mechanical properties of composite material boards, and achieve good mechanical properties, Low cost, good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Making Arundis polylactic acid composite board:

[0046] 1. Collect 1-year-old fresh and mature reed bamboo, then cut it off, split it, and flatten it into a reed bamboo board; cut the reed bamboo section into broken strips, flatten it and process it into a reed bamboo strip, and dry the reed bamboo strip to make it Its moisture content is 8% 10%; Plane and process the dried reed bamboo strips into a flattened reed bamboo board 1;

[0047] 2. Heat the polylactic acid resin masterbatch at a temperature of 175 degrees Celsius and a pressure of 3 MPa for 3 minutes to make a polylactic acid resin film 2 with a thickness of about 0.2 mm;

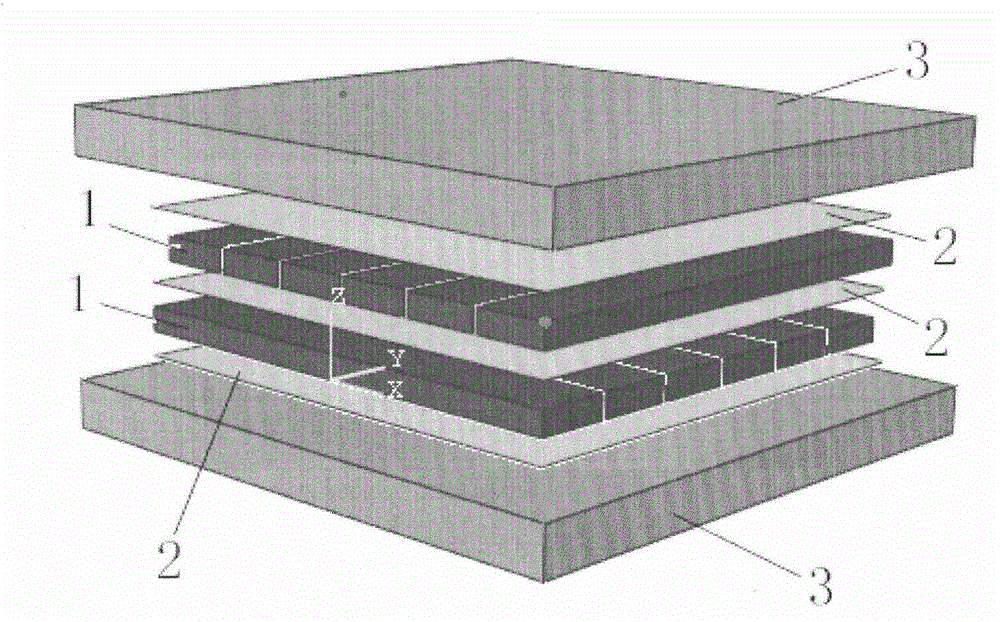

[0048] 3. Alternately arrange the flattened two-layer reed bamboo board 1 according to 0° / 90° lamination and the two-layer polylactic acid film 2, and place the release cloth on the upper and lower outer layers;

[0049] 4. Put all the above-prepared materials into a flat heat press, preheat at 180 degrees Celsius for 3 minutes, and heat ...

Embodiment 2

[0052] Preparation of Arundis sandwich composite board:

[0053] 1. Collect 1-year-old fresh and mature reed bamboo, then cut it off, split it, and flatten it into a reed bamboo board; cut the reed bamboo section into broken strips, flatten it and process it into a reed bamboo strip, and dry the reed bamboo strip to make it Its moisture content is 8%-10%; planing the dried reed bamboo strips into a flattened reed bamboo board 1;

[0054] 2. Heat the polypropylene resin masterbatch at a temperature of 180 degrees Celsius and a pressure of 3 MPa for 2 minutes to make a polypropylene resin film 2 with a thickness of about 0.2 mm;

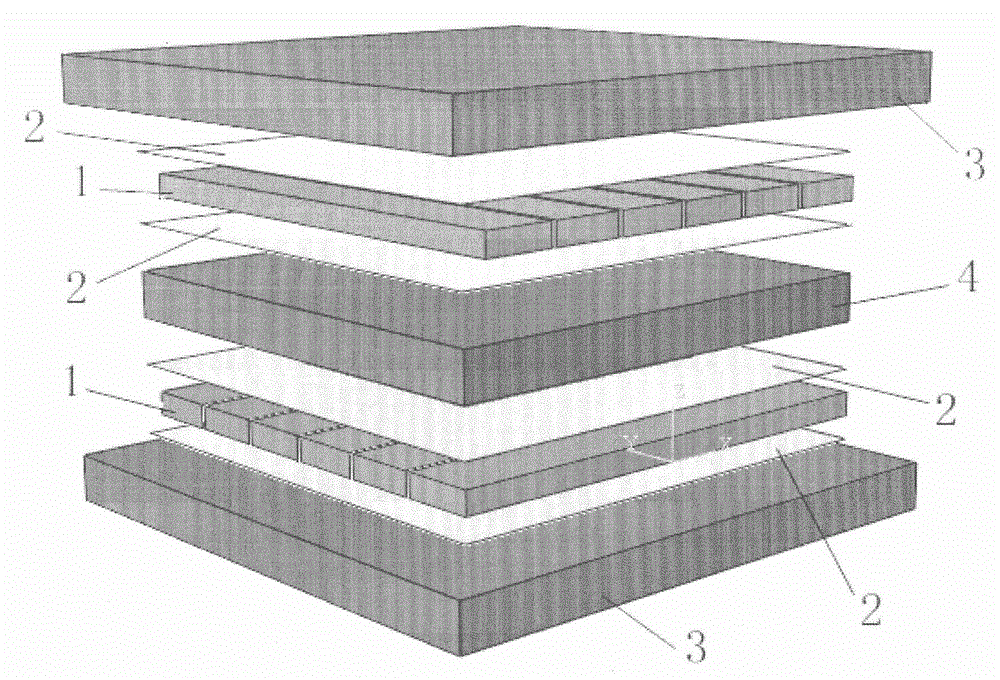

[0055] 3. Use wood particleboard with a thickness of 1cm as the interlayer 4. The selection requirements for the interlayer material are: it can withstand a high temperature of about 200 degrees Celsius and a pressure of about 2 MPa;

[0056] 4, the polypropylene resin film 2 is placed between the flattened two-layer reed bamboo board 1 and the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com