Production method of tribasic copper chloride

A production method and technology of copper chloride, applied in the direction of copper chloride, copper halide, etc., can solve the problems of strict crystallization conditions, product agglomeration, unstable crystal form of basic copper chloride, etc., and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of production method of basic cupric chloride, comprises the steps:

[0046] S1. Pretreatment: put 5m 3 Pour the acidic copper-containing etching waste liquid into the impurity removal reaction kettle, add 5 kg of sodium chloride under the condition of sufficient stirring, and stir for 10 minutes;

[0047] S2. Impurity removal: Add 5L hydrogen peroxide to the impurity removal reaction kettle, add sodium hydroxide to adjust its pH to 0.1 after 10 minutes of reaction, press filter after 20 minutes of reaction, and remove lead, arsenic, cadmium, mercury, iron and other impurities from the filtrate Enter the intermediate tank of acidic etching waste liquid;

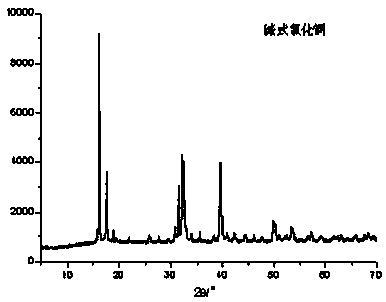

[0048]S3. Continuous production: preheat the clean water to 30°C, and under the condition of a stirring speed of 20r / min, the volume flow ratio of the alkaline copper-containing etching waste liquid and the acidic copper-containing etching waste liquid after removal of impurities is 0.1:1, Control the pH betwe...

Embodiment 2

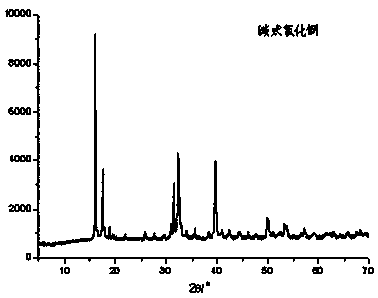

[0051] Except that sodium chloride is 400kg in S1, other conditions are with embodiment 1, and the appearance of the basic cupric chloride crystal prepared in embodiment 2 is brilliant green, and basic cupric chloride content (in terms of Cu 2 (OH) 3 Cl) is 98.6%, and the basic copper chloride X-ray diffraction figure that embodiment 2 makes is shown in figure 2 .

Embodiment 3

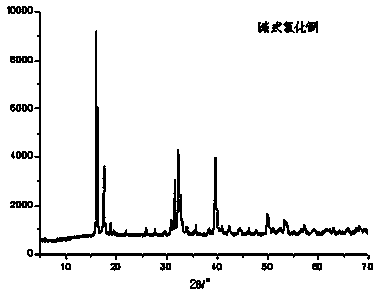

[0053] Except that sodium chloride is 250kg in S1, other conditions are the same as embodiment 1, and the appearance of the basic copper chloride crystal prepared by embodiment 3 is bright green, and the basic copper chloride content (in terms of Cu 2 (OH) 3 Cl) is 98.5%, and the basic copper chloride X-ray diffraction figure that embodiment 3 makes is shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com