Sludge drying method and system

A sludge drying and sludge technology, applied in dehydration/drying/concentrated sludge treatment, energy wastewater treatment, etc., can solve the problems of thermal drying construction cost, high operating cost, low air drying cost, and low air drying efficiency , to achieve the effect of resource utilization, best drying effect and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

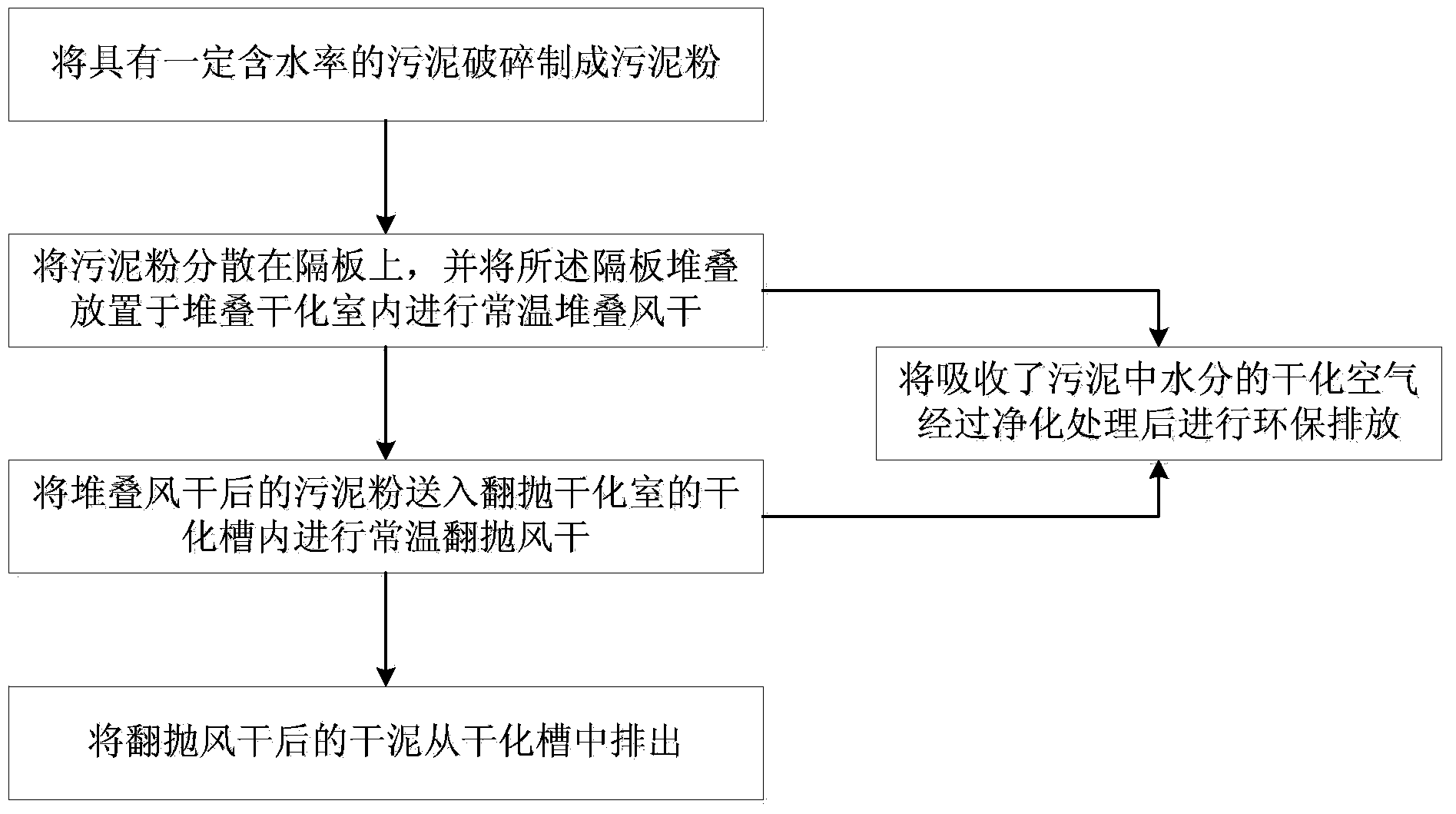

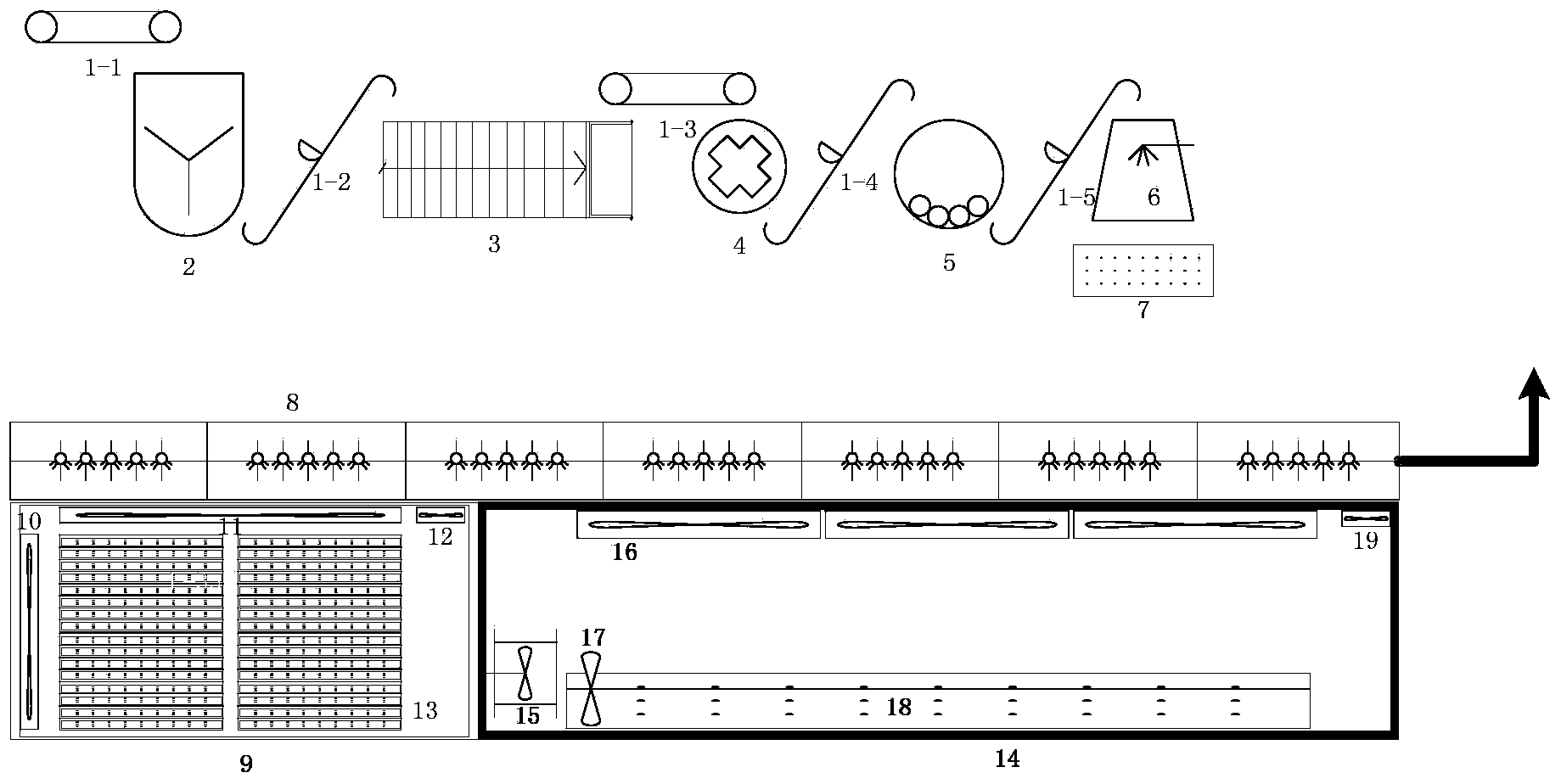

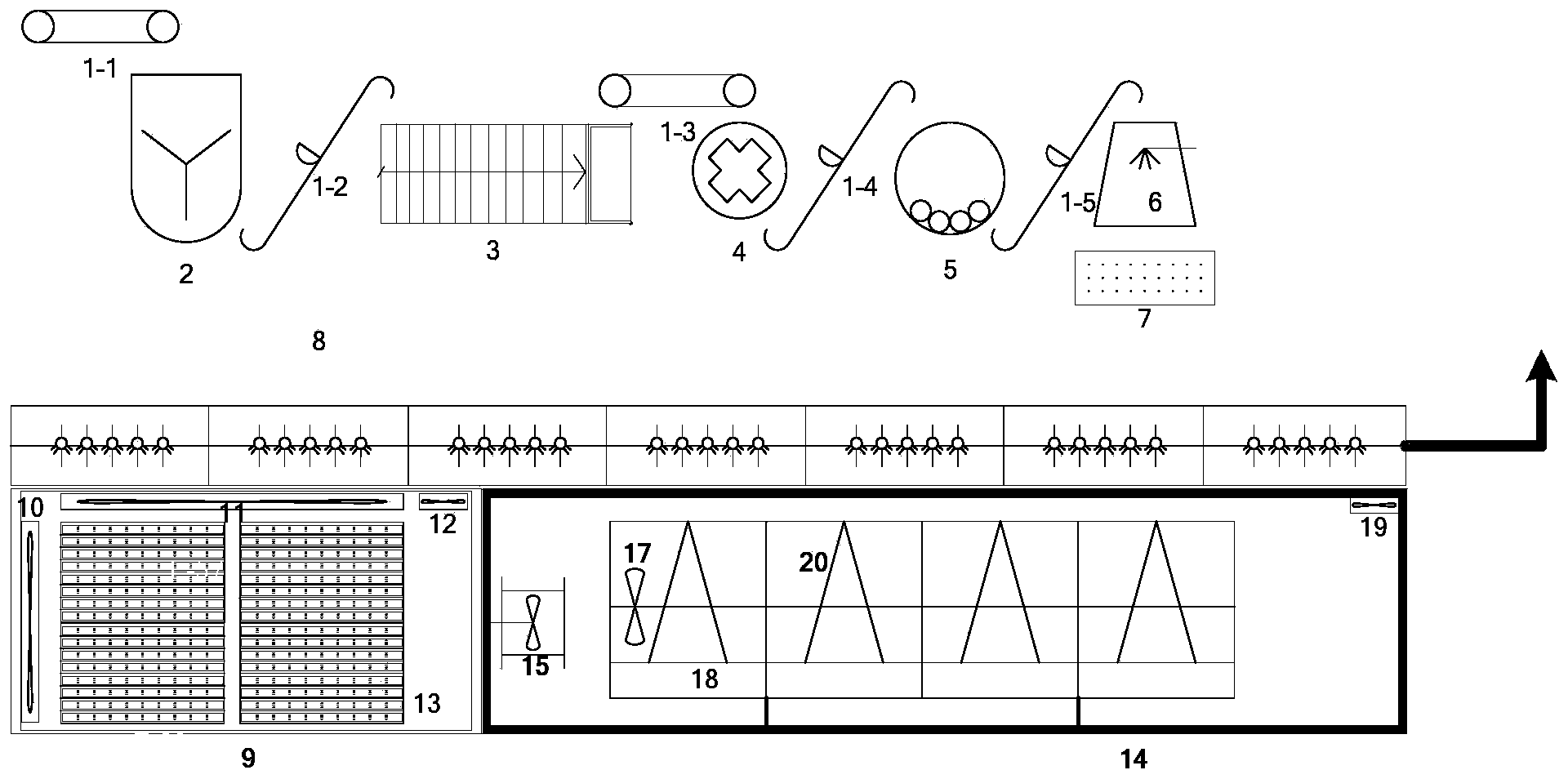

[0032] combine figure 1 , figure 2 As shown, the sludge drying method disclosed in the present invention adopts a three-stage drying method of mechanical pressing, stacking air drying and turning and throwing air drying to dry the wet sludge, that is, firstly dry the sludge powder and wet After the sludge is mixed, it is preliminarily dried by mechanical pressure filtration, and then the mud cake is crushed and stacked for air drying. Finally, the semi-dry sludge powder is put into the drying tank for overturning and air drying. In combination with the sludge drying system disclosed in the first preferred embodiment of the present invention, the sludge drying process specifically includes:

[0033] First, the dry sludge powder and wet sludge are sent into the agitating mixer 2 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com