Method for preparing foam glass with plant ash and waste glass

A foam glass and waste glass technology is applied in the field of preparing foam glass by using plant ash and waste glass to achieve the effects of low firing temperature, high economic benefit and improved thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

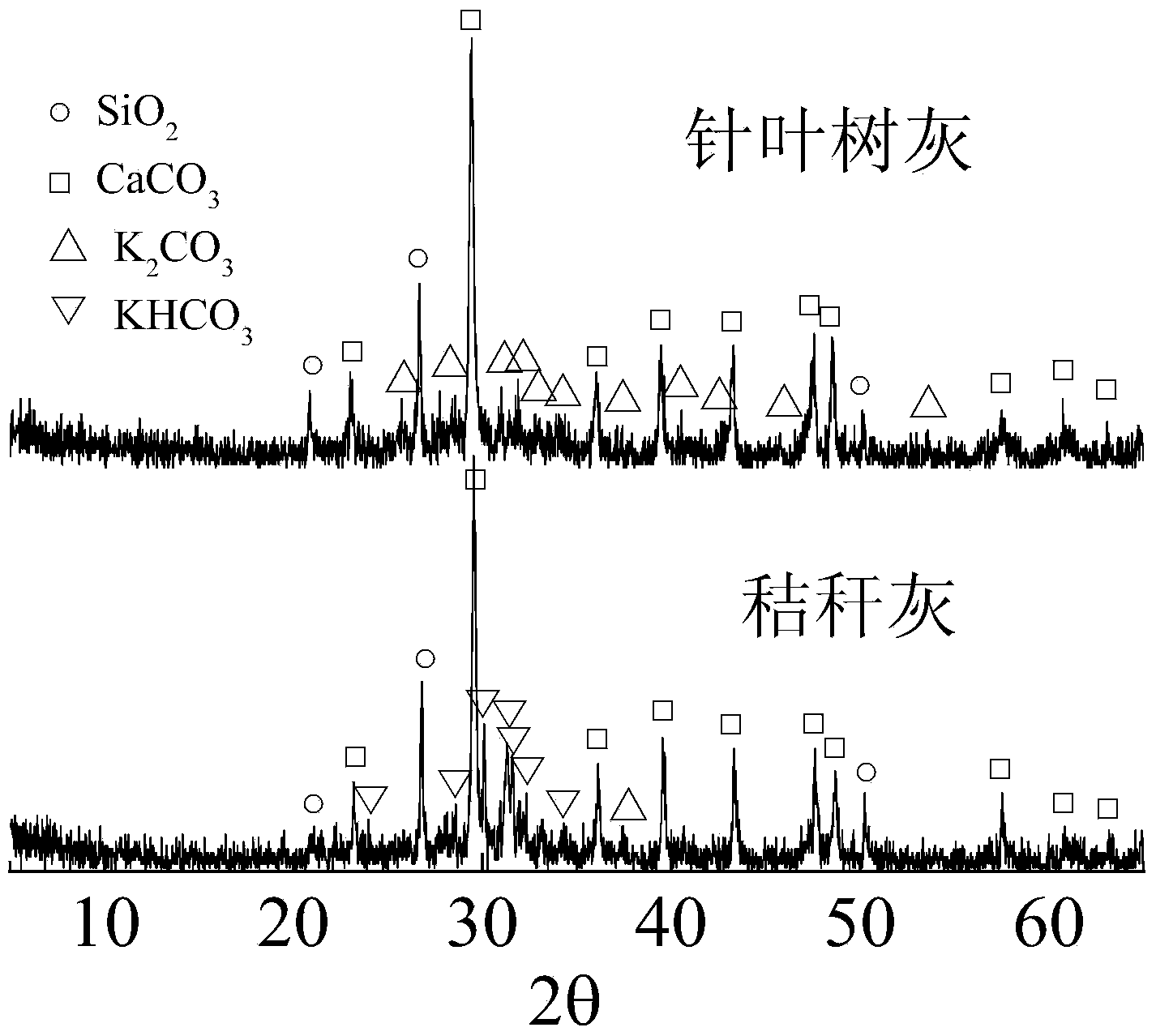

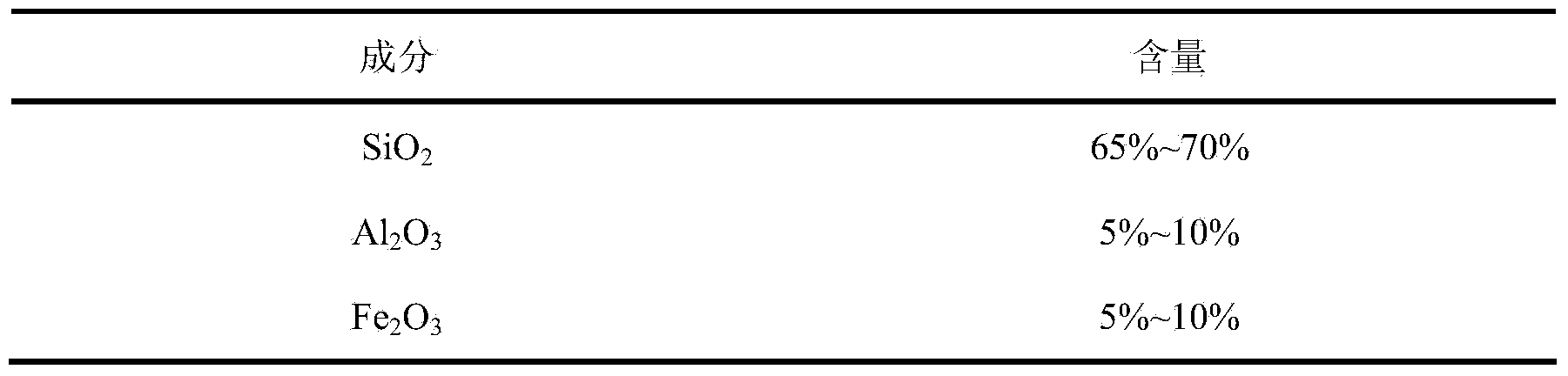

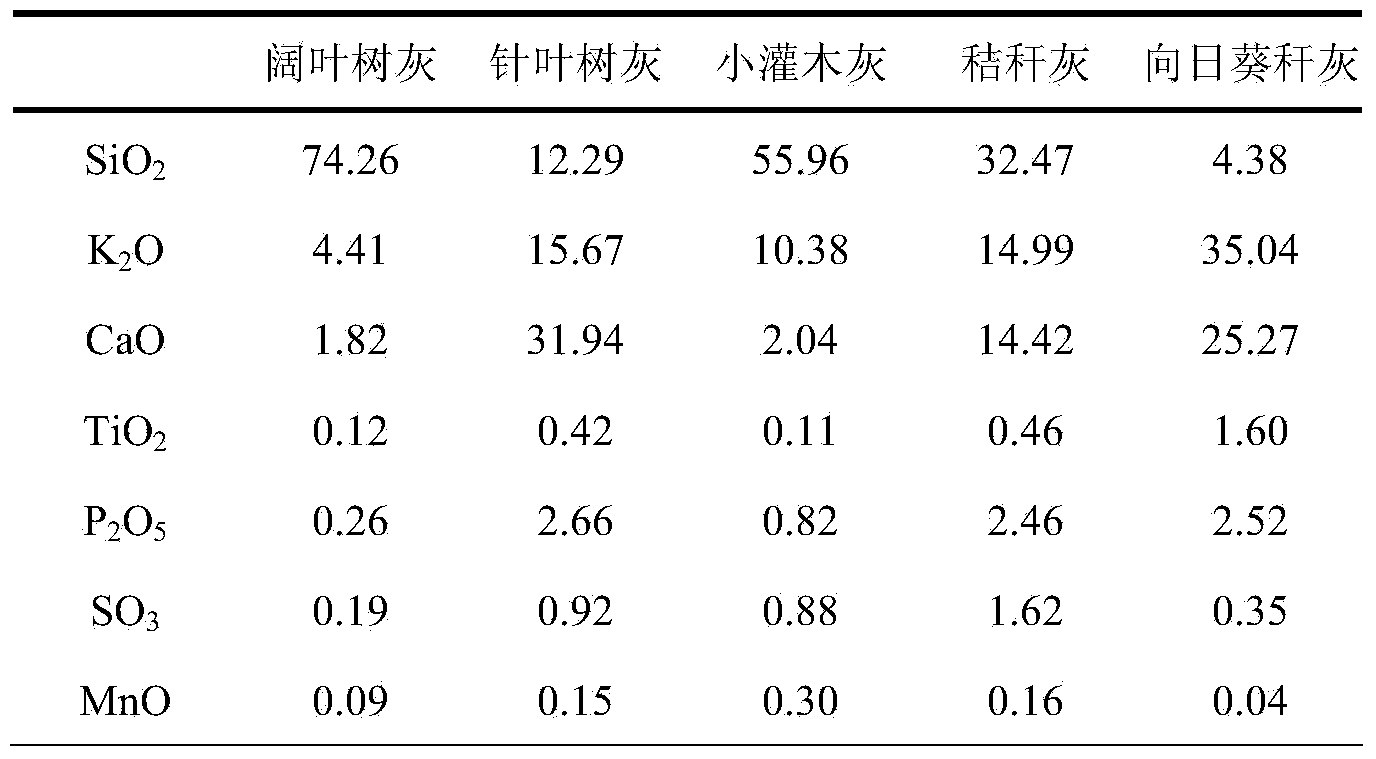

Method used

Image

Examples

Embodiment 1

[0052] Present embodiment prepares cellular glass as follows:

[0053] Weigh 30% of the total weight, straw ash with a particle size range of 200-250 mesh and 70% of the total weight, with a particle size range of 140-200 mesh waste flat glass; use a mixer to mix the two evenly to obtain a mixture; Pour the mixture into the mold (450mm×350mm×100mm) on the table, adjust the vibration frequency of the vibrating table to 50HZ, and the amplitude to 5mm, and vibrate for 2s in the vertical and horizontal directions to make the distribution of the mixture dense and uniform; put the mold into In the furnace, rise from room temperature to 400°C at a heating rate of 5°C / min, and hold for 25 minutes; then rise to 900°C at a heating rate of 20°C / min, and hold for 25 minutes; then cool down to 600°C at a cooling rate of 20°C / min, Insulate for 30 minutes; then cool down to room temperature at a cooling rate of 1°C / min to obtain foam glass. The parameters of the cellular glass prepared by t...

Embodiment 2

[0055] Present embodiment prepares cellular glass as follows:

[0056] Take by weighing 25% of the total weight, coniferous ash with a particle size range of 200-250 mesh and 75% of the total weight, with a particle size range of 140-200 mesh embossed glass; adopt a ball mill to mix the two evenly to obtain a mixture; Pour the mixture into the mold (450mm×350mm×100mm), adjust the vibration frequency of the vibrating table to 50HZ, and the amplitude to 5mm, and vibrate in the vertical and horizontal directions for 3s to make the distribution of the mixture dense and uniform; put the mold into the furnace Inside, from room temperature to 450°C at a heating rate of 6°C / min, and hold for 20 minutes; then rise to 950°C at a heating rate of 15°C / min, and hold for 20 minutes; 30min; then cool down to room temperature at a cooling rate of 1°C / min to finally obtain foam glass. The parameters of the cellular glass prepared by this method are respectively: bulk density 165kg / m 3 ; Comp...

Embodiment 3

[0058] Present embodiment prepares cellular glass as follows:

[0059] Weighing sunflower stalk ash accounting for 20% of the total weight and having a particle size range of 200-250 mesh and waste bottle glass accounting for 80% of the total weight and having a particle size range of 140-200 mesh; using a mixer to mix the two evenly to obtain a mixture; Pour the mixture into the mold (450mm×350mm×100mm) on the vibrating table, adjust the vibration frequency of the vibrating table to 50HZ, and the amplitude to 5mm, and vibrate for 5s in the vertical and horizontal directions to make the distribution of the mixture dense and even; place the mold Put it into the furnace, raise the temperature from room temperature to 400°C at a heating rate of 7°C / min, and keep it for 25 minutes; then raise it to 900°C at a heating rate of 20°C / min, and keep it for 25 minutes; then cool it down to 600°C at a cooling rate of 15°C / min ℃, keep warm for 30min; then cool down to room temperature at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com