Preparation method for acyclic compound used as foaming agent

A technology of cyclic compounds and foaming agents, which is applied in the field of preparation of acyclic compounds, can solve the problems of complex components, many by-products, and restrictions on flotation indicators, and achieve the effects of optimized flotation performance, short reaction time, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

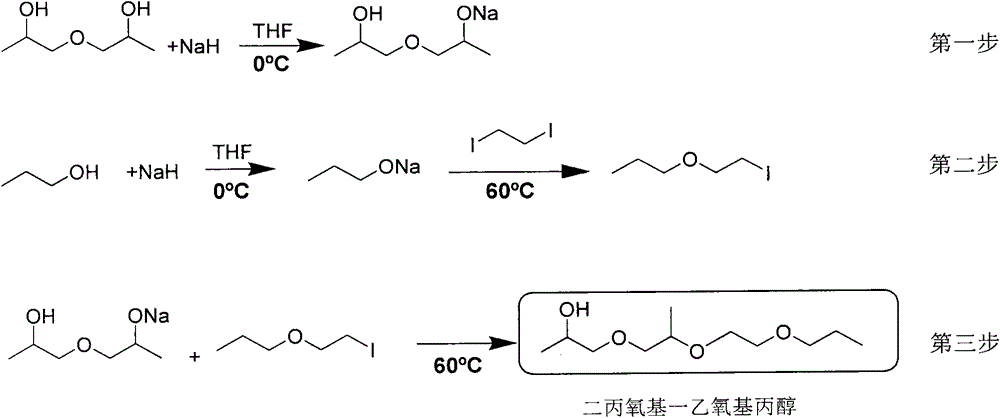

[0029] figure 1 is the reaction route diagram for the synthesis of novel blowing agents. combine figure 1, generating final products (such as dipropoxyl-ethoxypropanol) including:

[0030] Step 1: Add 20L of tetrahydrofuran solvent and 48g of sodium hydride into #1 reactor respectively, and stir until the sodium hydride is completely dissolved. Then 160.8g of dipropylene glycol was gradually added into the solution, and the reactants were reacted for two hours at 0°C to generate sodium dipropylene glycol;

[0031] Step 2: Add 20L of tetrahydrofuran solvent and 48g of sodium hydride into #2 reactor respectively, and stir until the sodium hydride is completely dissolved. Then, 72g of 1-propanol was gradually dropped into the solution, and the reactants were reacted for two hours at 0°C to generate sodium 1-propoxide;

[0032] Step 3: After two hours, gradually add 310g of 1,2-diiodoethane into #2 reactor, raise the temperature and keep it at 60°C, and react with sodium 1-pro...

Embodiment 2

[0040] Similar to the synthetic process of Example 1, the target product in this example is tripropoxy-ethoxypropanol. The generation steps include:

[0041] Step 1: Add 20L of tetrahydrofuran solvent and 48g of sodium hydride into #1 reactor respectively, and stir until the sodium hydride is completely dissolved. Then, 230.4 g of tripropylene glycol was gradually added into the solution, and the reactants were reacted for two hours at 0° C. to generate sodium tripropylene glycol;

[0042] Step 2: Add 20L of tetrahydrofuran solvent and 48g of sodium hydride into #2 reactor respectively, and stir until the sodium hydride is completely dissolved. Then, 72g of 1-propanol was gradually dropped into the solution, and the reactants were reacted for two hours at 0°C to generate sodium 1-propoxide;

[0043] Step 3: After two hours, gradually add 310g of 1,2-diiodoethane into #2 reactor, raise the temperature and keep it at 60°C, and react with sodium 1-propoxide in tetrahydrofuran s...

Embodiment 3

[0048] Similar to the synthetic process of Example 1, the target product in this example is tripropoxy-ethoxypentanol. The generation steps include:

[0049] Step 1: Add 20L of tetrahydrofuran solvent and 48g of sodium hydride into #1 reactor respectively, and stir until the sodium hydride is completely dissolved. Then, 230.4 g of tripropylene glycol was gradually added into the solution, and the reactants were reacted for two hours at 0° C. to generate sodium tripropylene glycol;

[0050] Step 2: Add 20L of tetrahydrofuran solvent and 48g of sodium hydride into #2 reactor respectively, and stir until the sodium hydride is completely dissolved. Next, 105.6 g of 1-pentanol was gradually dropped into the solution, and the reactants were reacted for two hours at 0° C. to generate sodium 1-pentoxide;

[0051] Step 3: After two hours, gradually add 310g of 1,2-diiodoethane into #2 reactor, raise the temperature and keep it at 60°C, and react with sodium 1-pentoxide in tetrahydrof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com