Preparation method of organic intermediate benzoylacetone

A technology of benzoylacetone and benzoylacetone, which is applied in the field of preparation of organic intermediate benzoylacetone, can solve the problems of high raw material price and high cost, and achieves short reaction time, low cost and little environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

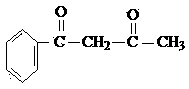

Image

Examples

Embodiment 1

[0013] In a four-necked reaction flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 16.8g of diketene, 47.2g of benzene, and 0.4g of a polymerization inhibitor in sequence, start the stirrer, and control the reaction time when the temperature is 85-105°C 5-10h, after stopping the reaction, add 1.5 times the total mass of benzene with hot water at 70-80°C, wash with water, separate the water phase, heat the remaining organic phase to reflux to separate water, decolorize with activated carbon, and filter the organic phase Perform cooling, crystallization and filtration to obtain the benzoylacetone product with a yield of 90.06% and a melting point of 60-61°C.

Embodiment 2

[0015] In a four-necked reaction flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 16.8g of diketene, 59.5g of benzene, and 0.8g of a polymerization inhibitor in sequence, start the stirrer, and control the reaction time when the temperature is 85-105°C 5-10h, after stopping the reaction, add 1.5 times the total mass of benzene with hot water at 70-80°C, wash with water, separate the water phase, heat the remaining organic phase to reflux to separate water, decolorize with activated carbon, and filter the organic phase Perform cooling, crystallization and filtration to obtain the benzoylacetone product with a yield of 90.84% and a melting point of 60-61°C.

Embodiment 3

[0017] In a four-necked reaction flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 16.8g of diketene, 59.5g of benzene, and 1.0g of a polymerization inhibitor in sequence, start the stirrer, and control the reaction time when the temperature is 85-105°C 5-10h, after stopping the reaction, add 1.5 times the total mass of benzene with hot water at 70-80°C, wash with water, separate the water phase, heat the remaining organic phase to reflux to separate water, decolorize with activated carbon, and filter the organic phase Cool down, crystallize and filter to obtain the benzoylacetone product with a yield of 91.32% and a melting point of 60-61°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com