Preparation method of praseodymium-based multi-ligand thiofide

A rubber vulcanization and multi-ligand technology, which is applied in chemical instruments and methods, organic chemistry, and compounds containing elements of group 3/13 of the periodic table, can solve problems such as poor solubility, simplify the process, and improve dissolution Sexuality and consumption-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

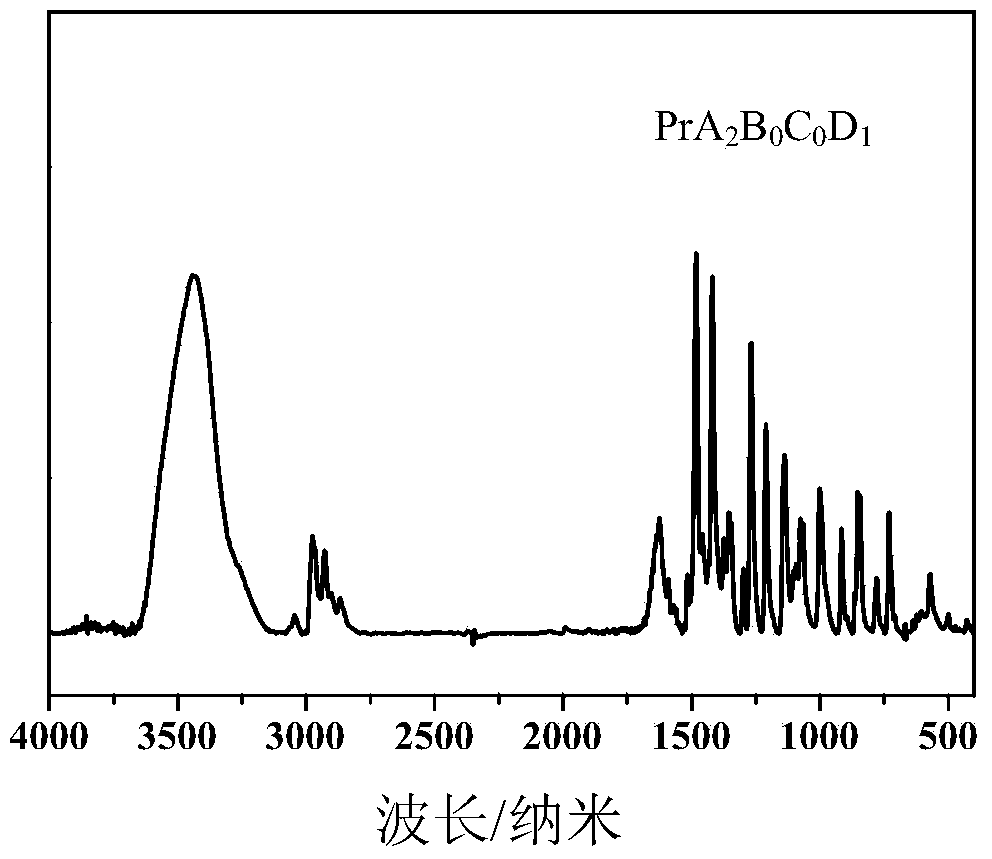

Embodiment 1

[0043] The preparation method of accelerator:

[0044] 0.01molPrCl 3 Dissolve in absolute ethanol at 60°C, dissolve 0.02mol potassium ethyl xanthate in absolute ethanol solution at 60°C, and dissolve 0.01mol o-phenanthroline in absolute ethanol solution at 60°C. Fully mix the ethanol solution of potassium ethyl xanthate and the ethanol solution of phenanthroline to obtain a mixed solution. Then the above mixed solution was added dropwise to PrCl 3 in anhydrous ethanol solution, stirred in an oil bath at 80°C for 6h and filtered, and the precipitate was washed with anhydrous ethanol, and placed in CaCl 2 Dry in a desiccant desiccator at 20°C to constant mass to obtain a light green powder, the target product PrA 2 B 0 C 0 D. 1 .

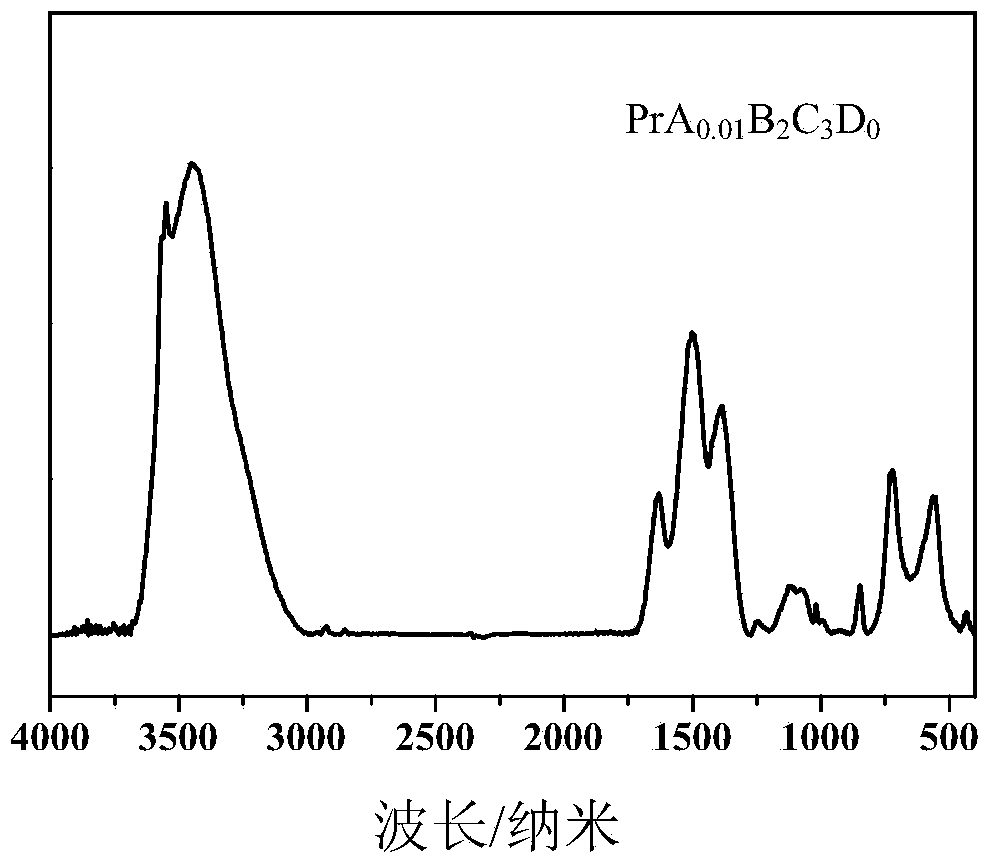

Embodiment 2

[0046] The preparation method of accelerator:

[0047] 0.01molPrCl 3 Dissolve in absolute ethanol at 60°C, dissolve 0.0001mol potassium ethyl xanthate in absolute ethanol solution at 60°C, dissolve 0.02mol sodium diethyldithiocarbamate in absolute ethanol solution at 60°C In, 0.03mol methacrylic acid was dissolved in absolute ethanol solution at 60°C. Fully mix the ethanol solution of potassium ethyl xanthate, the ethanol solution of sodium diethyldithiocarbamate and the ethanol solution of methacrylic acid to obtain a mixed solution. Then the above mixed solution was added dropwise to PrCl 3 in anhydrous ethanol solution, stirred in an oil bath at 80°C for 6h and filtered, and the precipitate was washed with anhydrous ethanol, and placed in CaCl 2 Dry in a desiccant desiccator at 20°C to a constant mass to obtain a green powder, the target product PrA 0.01 B2 C 3 D. 0 .

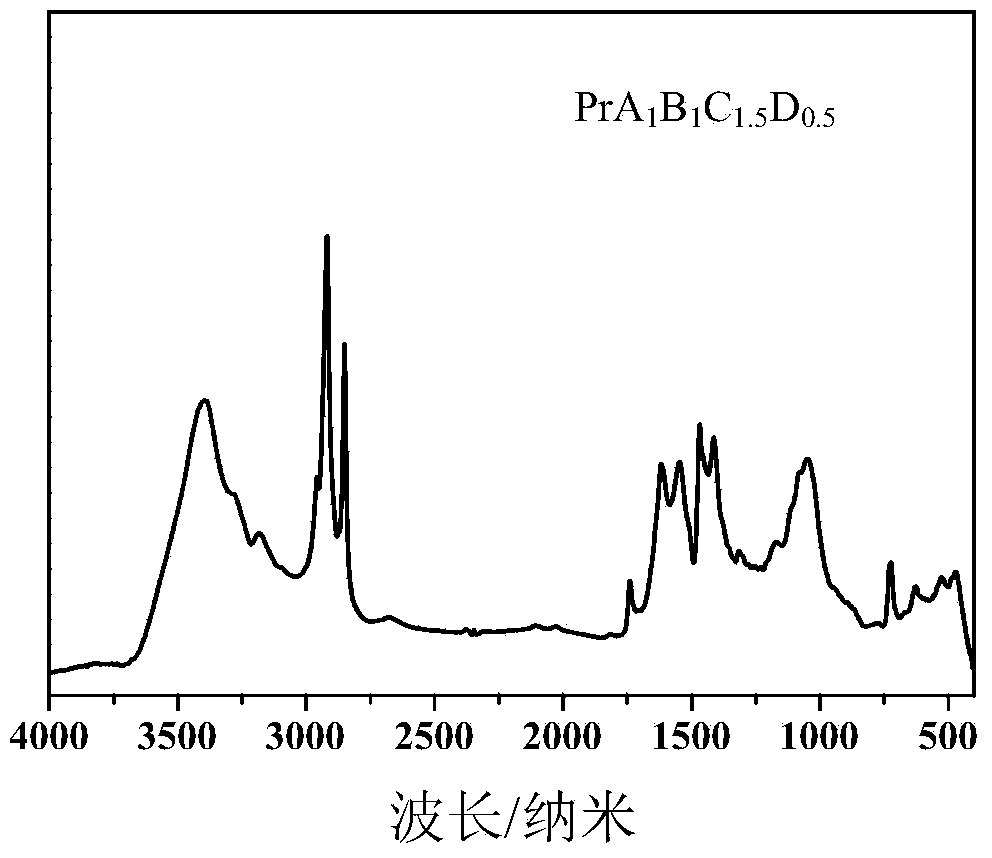

Embodiment 3

[0049] The preparation method of accelerator:

[0050] 0.01molPrCl 3 Dissolve in absolute ethanol at 60°C, dissolve 0.01mol potassium ethyl xanthate in absolute ethanol solution at 60°C, dissolve 0.01mol sodium diethyldithiocarbamate in absolute ethanol solution at 60°C In, 0.015mol methacrylic acid was dissolved in 60°C absolute ethanol solution, and 0.005mol o-phenanthroline was dissolved in 60°C absolute ethanol solution. Fully mix the ethanol solution of potassium ethyl xanthate, the ethanol solution of sodium diethyldithiocarbamate, the ethanol solution of methacrylic acid and the ethanol solution of o-phenanthroline to obtain a mixed solution. Then the above mixed solution was added dropwise to PrCl 3 in anhydrous ethanol solution, stirred in an oil bath at 80°C for 6h and filtered, and the precipitate was washed with anhydrous ethanol, and placed in CaCl 2 Dry in a desiccant desiccator at 20°C to a constant mass to obtain a green powder, the target product PrA 1 B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com