A kind of rubber accelerator diethyldithiocarbamate sulfone and its preparation method and application

A technology of diethyldithiocarbamate and sodium diethyldithiocarbamate, applied in organic chemistry and other directions, can solve the problems of waste water polluting the environment and not conforming to the concept of green chemistry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

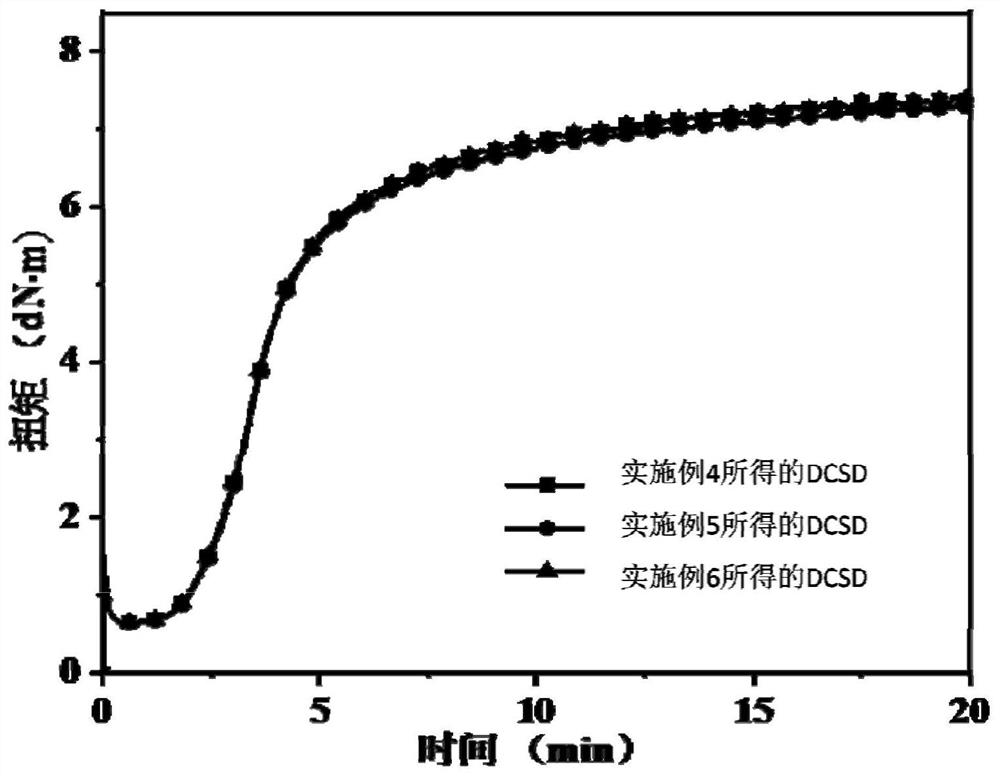

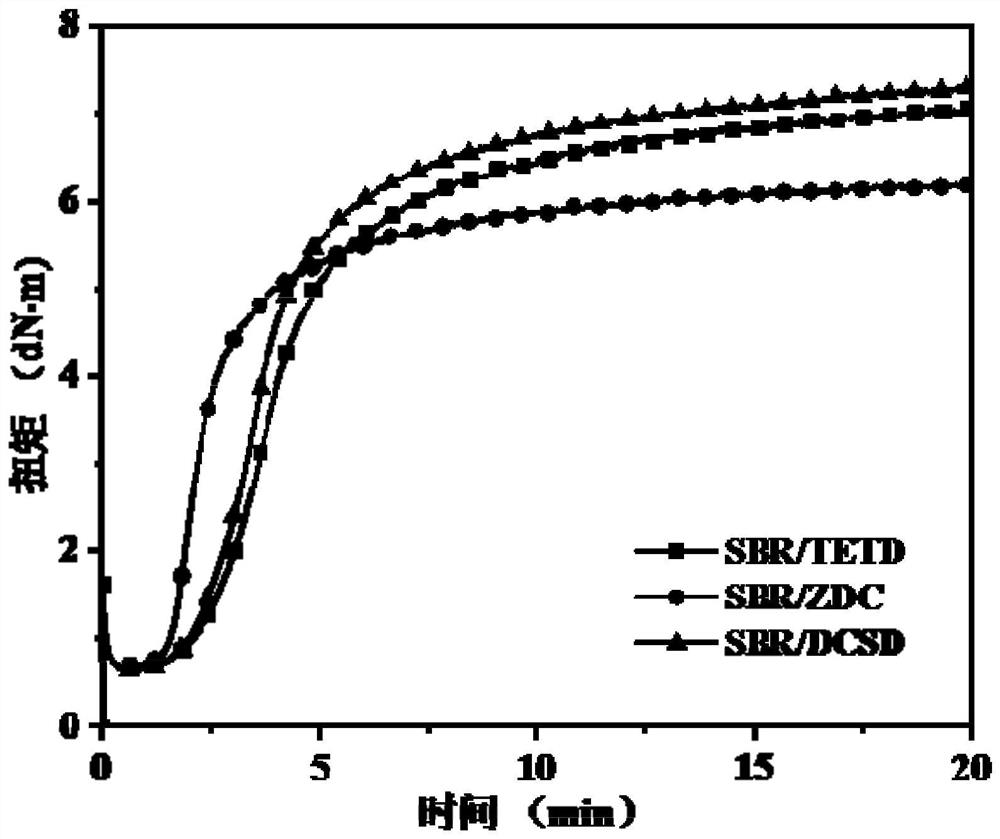

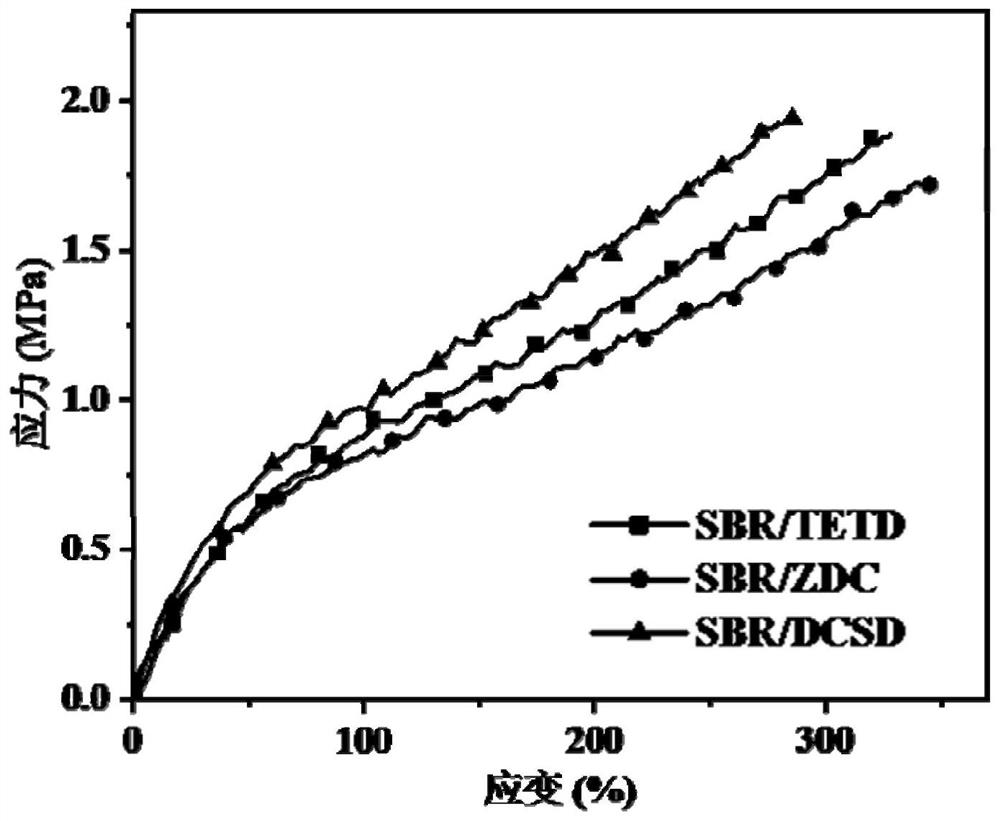

Embodiment 1

[0033] 11.25g sodium diethyldithiocarbamate (0.05mol) was dispersed in 150ml cyclohexane under stirring at 300rpm, and then 3.04g sulfonyl chloride (0.0225mol) was added dropwise to sodium diethyldithiocarbamate In the cyclohexane dispersion liquid, control the temperature at 0 ℃, and stir for 60min; after the reaction is finished, the rubber accelerator diethyl diethyl diethyl diethyl diethyl diethyl diethyl diacrylate is obtained by suction filtration, washing, drying, pulverization and sieving (mesh 400 mesh). Thiocarbamate sulfone; the yield of the obtained product is 76.4%.

Embodiment 2

[0035] 11.25g of sodium diethyldithiocarbamate (0.05mol) was dispersed in 150ml of petroleum ether under stirring at 300rpm, and then 4.05g of sulfonyl chloride (0.03mol) was added dropwise to the mixture of sodium diethyldithiocarbamate. In the petroleum ether dispersion liquid, the temperature was controlled at 10° C., and stirred for 60 minutes; after the reaction was completed, the rubber accelerator diethyl disulfide was prepared by suction filtration, washing, drying, pulverization, and sieving (mesh 400 mesh). Carbamate sulfone; the yield of the obtained product is 91.0%.

Embodiment 3

[0037] 11.25g of sodium diethyldithiocarbamate (0.05mol) was dispersed in 150ml of hexane under stirring at 300rpm, and 5.06g of sulfonyl chloride (0.0375mol) was added dropwise to the mixture of sodium diethyldithiocarbamate. In the hexane dispersion, the temperature was controlled at 15 ° C, and stirred for 60 min; after the reaction was completed, the rubber accelerator diethyldithiocyanate was prepared by suction filtration, washing, drying, pulverization, and sieving (400 mesh sieves). Carbamate sulfone; the yield of the obtained product is 81.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com