Low-halogen flame retarding PVC (Polyvinyl Chloride) pipe material and preparing method thereof

A PVC pipe and auxiliary flame retardant technology, applied in the direction of hoses, pipes, rigid pipes, etc., can solve the problems of unsatisfactory flame retardant effect, increase product cost, difficult to achieve, etc., and achieve low production cost and flame retardant performance. Good, simple craftsmanship

Inactive Publication Date: 2014-05-28

ANHUI LAND GRP

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the flame retardant formula is unreasonable, the flame retardant effect is not ideal. If the flame retardant performance is improved by increasing the amount of addition, it will increase the cost of the product and affect the bending performance of the material, making it difficult to meet the national standards.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

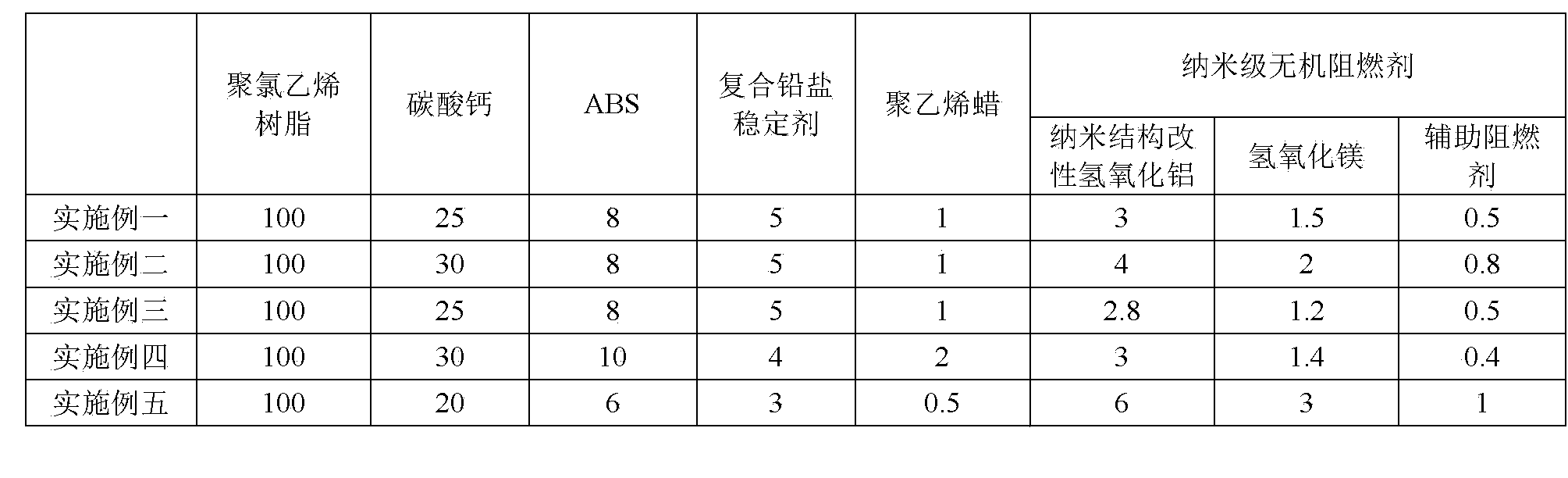

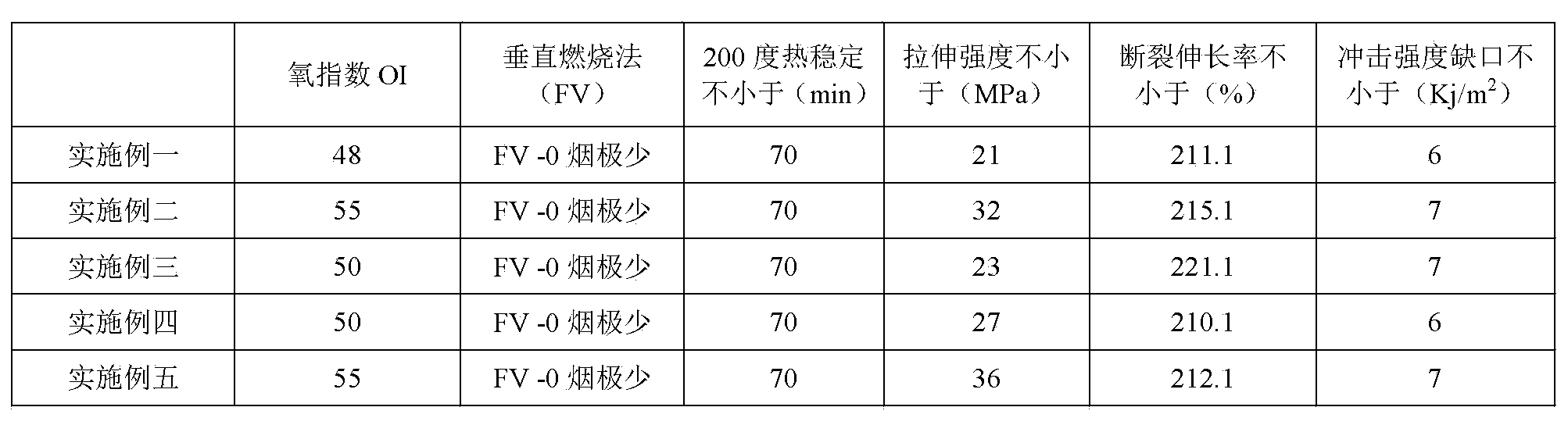

[0012] The following is a list of components and parts by weight of the low-halogen flame-retardant PVC pipe material of the embodiment of the present invention:

[0013] Table 1 Component and Content Table

[0014]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a low-halogen flame retarding PVC (Polyvinyl Chloride) pipe material. The low-halogen flame retarding PVC pipe material comprises the following ingredients in part by weight: 80-120 parts of polyvinyl chloride resin in a grain diameter of 0.1-0.2mm, 20-40 parts of calcium carbonate in a grain diameter of 300-500 mesh, 5-15 parts of an impact modifier ABS, 2-5 parts of a sulfur-containing organic tin salt thermal stabilizer, 0.5-2 parts of lubricant oxidized polyethlene wax, 2-5 parts of structure modified aluminum hydroxide in a grain diameter of 100-150 nanometer, 1-3 parts of magnesium hydroxide in a grain diameter of 1-10 microns and 0.5-2 parts of an auxiliary flame retardant. The low-halogen flame retarding PVC pipe material has excellent flame retarding performance, and the flame retarding oxygen index can reach more than 40. The low-halogen flame retarding PVC pipe has great rigidity, and excellent thermal resistance and ageing resistance. The invention further discloses a preparing method for the PVC pipe material. The preparing method has the advantages of low requirement on equipment, low manufacture cost and simple processing technology.

Description

technical field [0001] The invention belongs to the technical field of polyvinyl chloride composite materials, and in particular relates to a low-halogen flame-retardant PVC pipe material, and also relates to a preparation method of the PVC pipe material. Background technique [0002] At present, polyvinyl chloride products occupy a considerable proportion in construction, transportation, electronic appliances, and household daily necessities. We all know. Polyvinyl chloride itself is flame retardant and made of soft and hard products by adding various additives to make it non-flammable. Once it catches fire, it will cause the flame to spread rapidly and expand thick smoke and poisonous gas, which will bring harm to fire fighting and people's lives and property. to a huge loss. Therefore, endowing high polymer products with flame retardancy has become a top priority. Many countries have formulated various flame retardant standards for polymer materials. It is stipulated ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/06C08L55/02C08K13/06C08K3/26C08K5/58C08K3/22F16L9/12F16L11/04

Inventor 叶家和叶耿堂杨芸吴友山

Owner ANHUI LAND GRP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com